Welding method of fiber boards

A welding method and fiberboard technology, applied in the field of fiberboard welding, can solve problems such as low welding success rate, difficult welding, easy bending, etc., and achieve the effects of improving quality, improving welding efficiency, and increasing success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

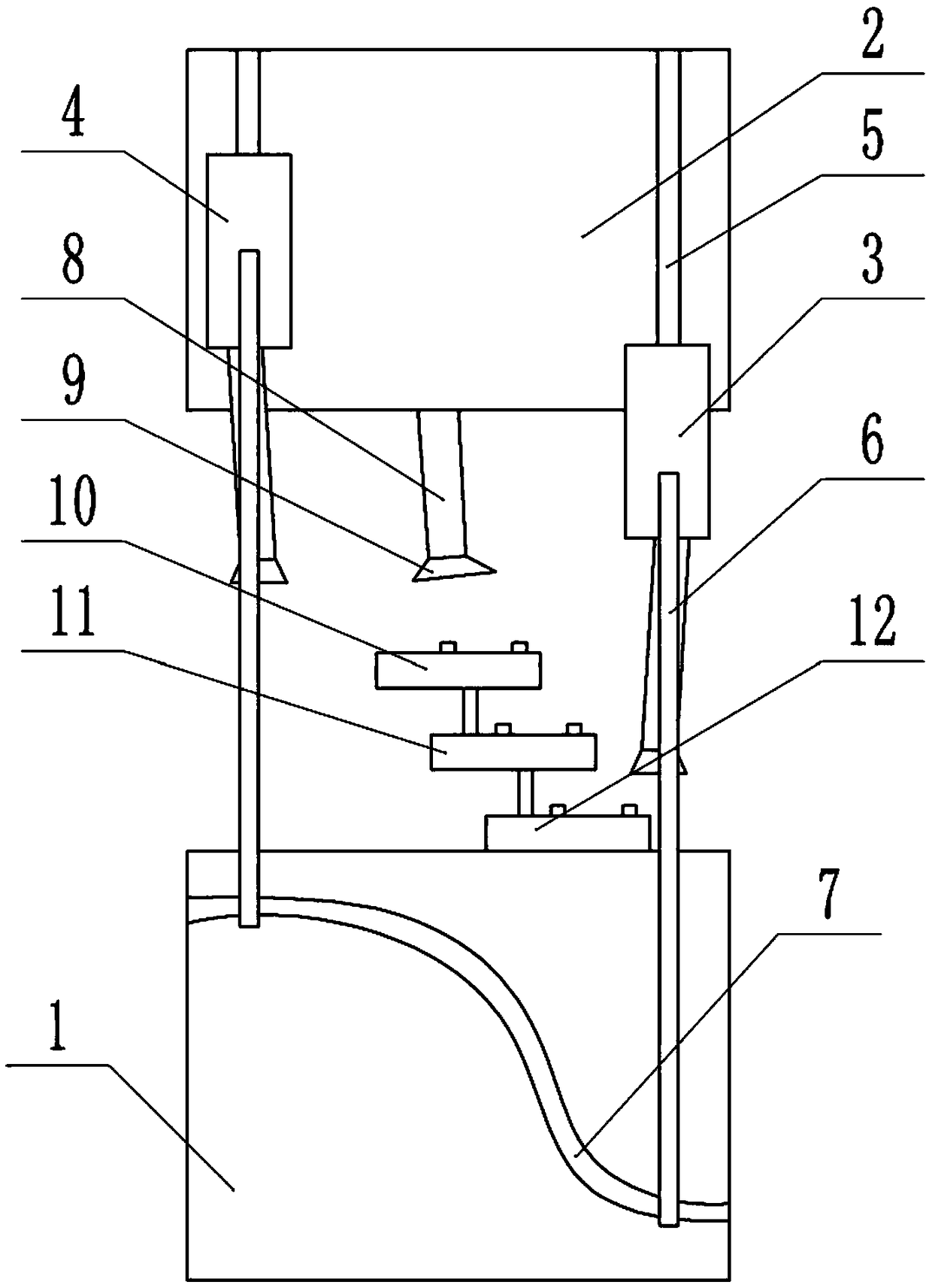

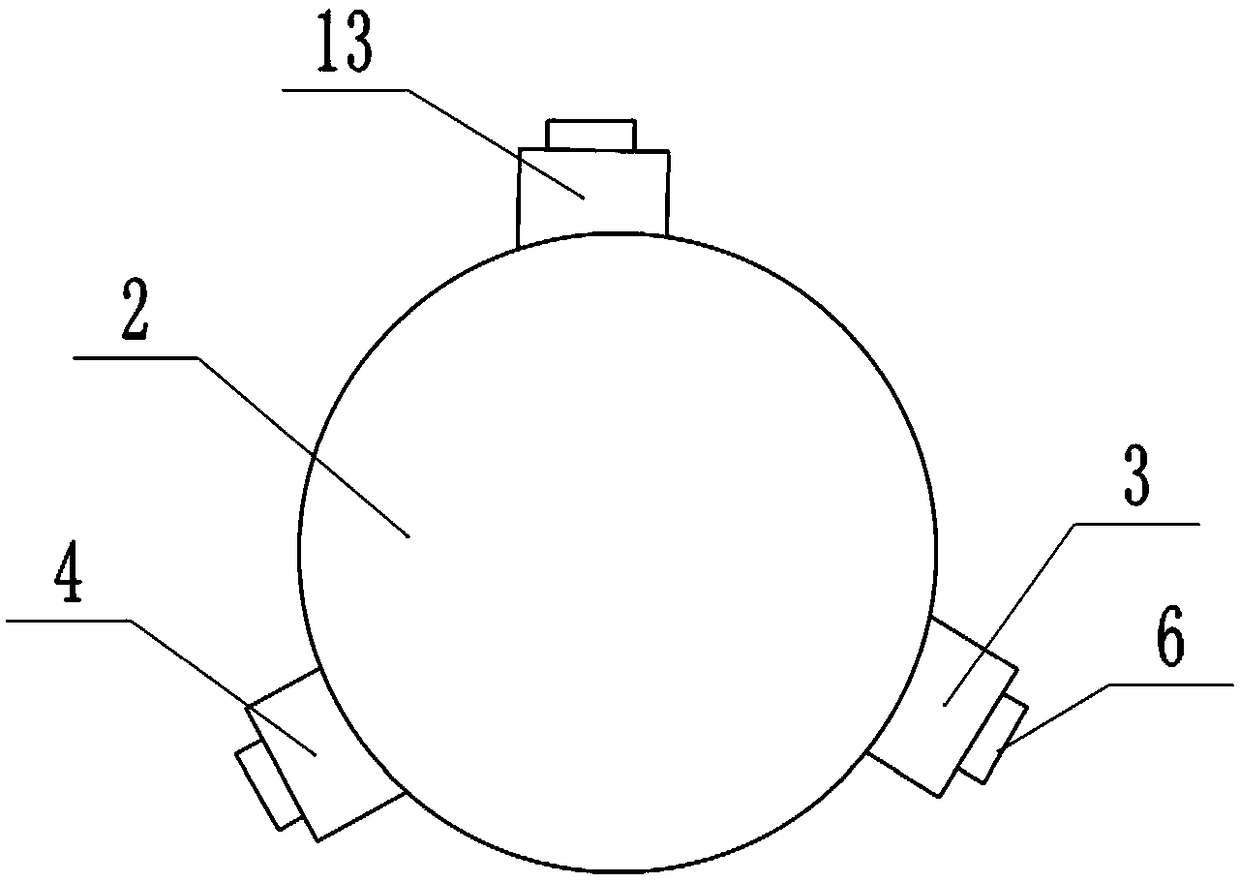

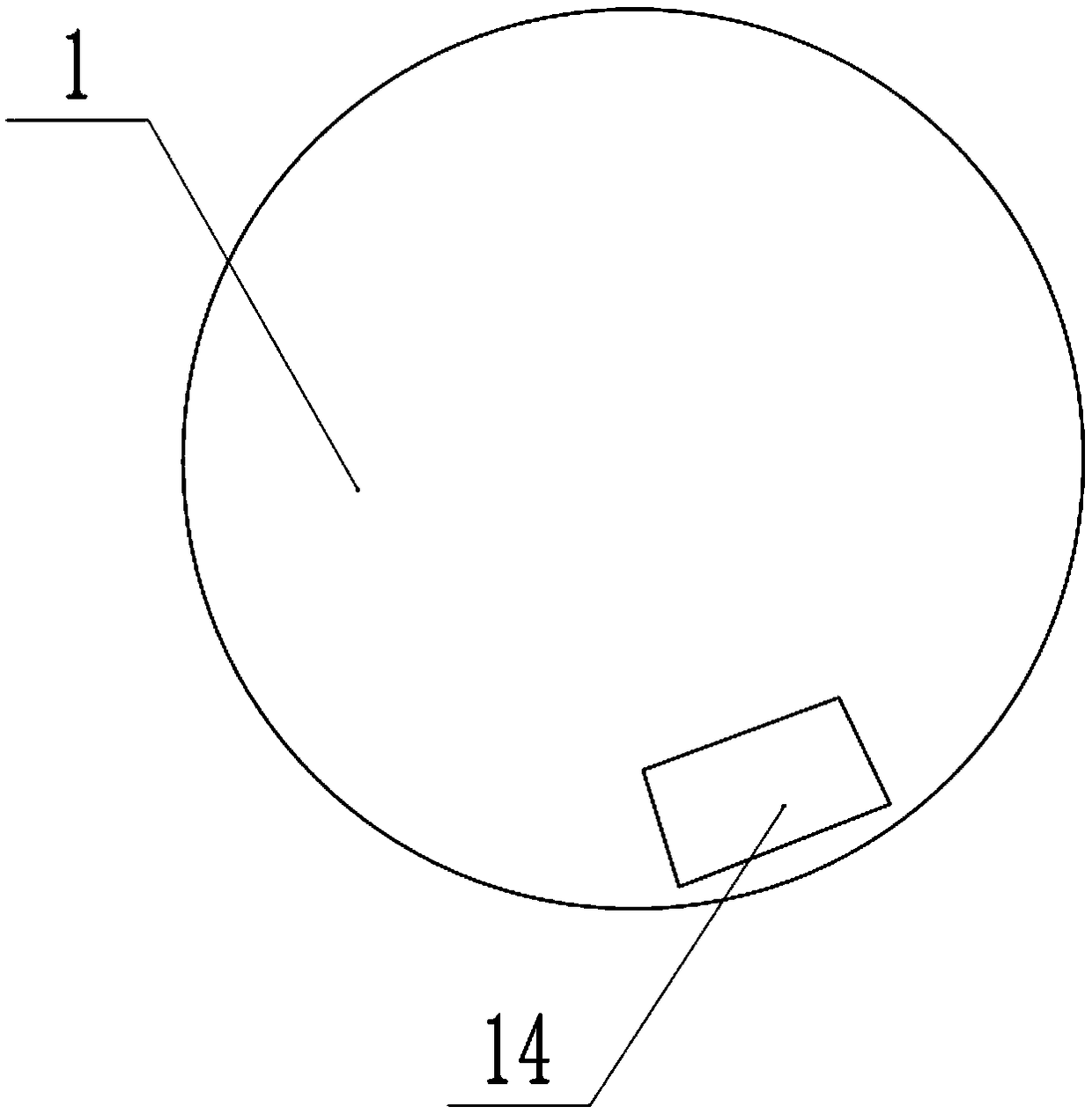

[0023] The reference signs in the drawings of the description include: rotating column 1, fixed column 2, first box body 3, third box body 4, chute 5, vertical bar 6, arc groove 7, through pipe 8, nozzle 9, The first support plate 10 , the second support plate 11 , the third support plate 12 , the second box body 13 , the support member 14 , the node 17 , and the thermal fuse 18 .

[0024] The embodiment is basically as attached Figure 1-Figure 4 Shown: a kind of welding method of fiberboard, comprises the following steps:

[0025] A. Material preparation: prepare the overlapped fiberboard, and prepare flux, tin and antioxidant.

[0026] B. Put the fiberboard on the movable support 14, combine figure 1 As shown, the support 14 includes a first support plate 10, a second support plate 11 and a third support plate 12 from top to bottom, between the first support plate 10 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com