Control system for pressure joint process of detonating cord

A process control system and detonating cord technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of high production cost, insufficient processing accuracy, low work efficiency, etc., and achieve the goal of feeding process Safe and reliable, high crimping precision, and the effect of precise feeding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

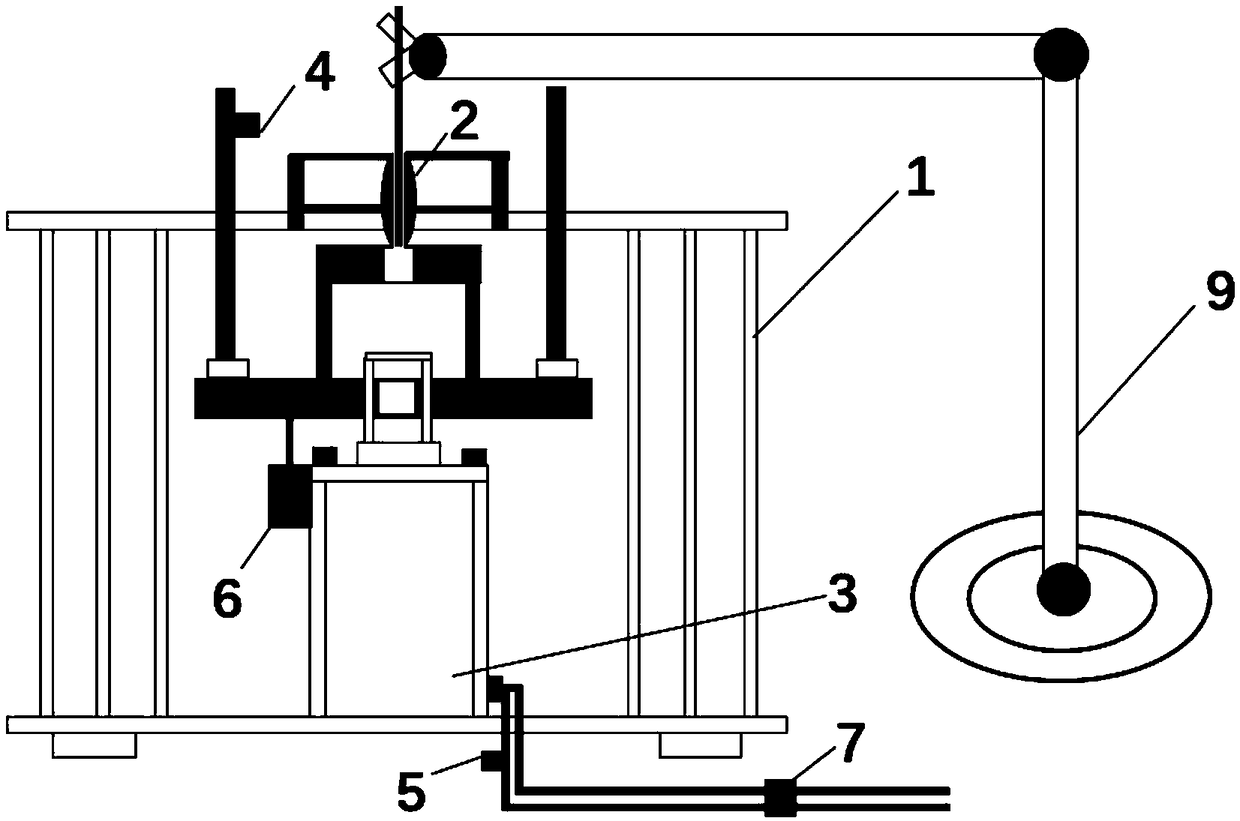

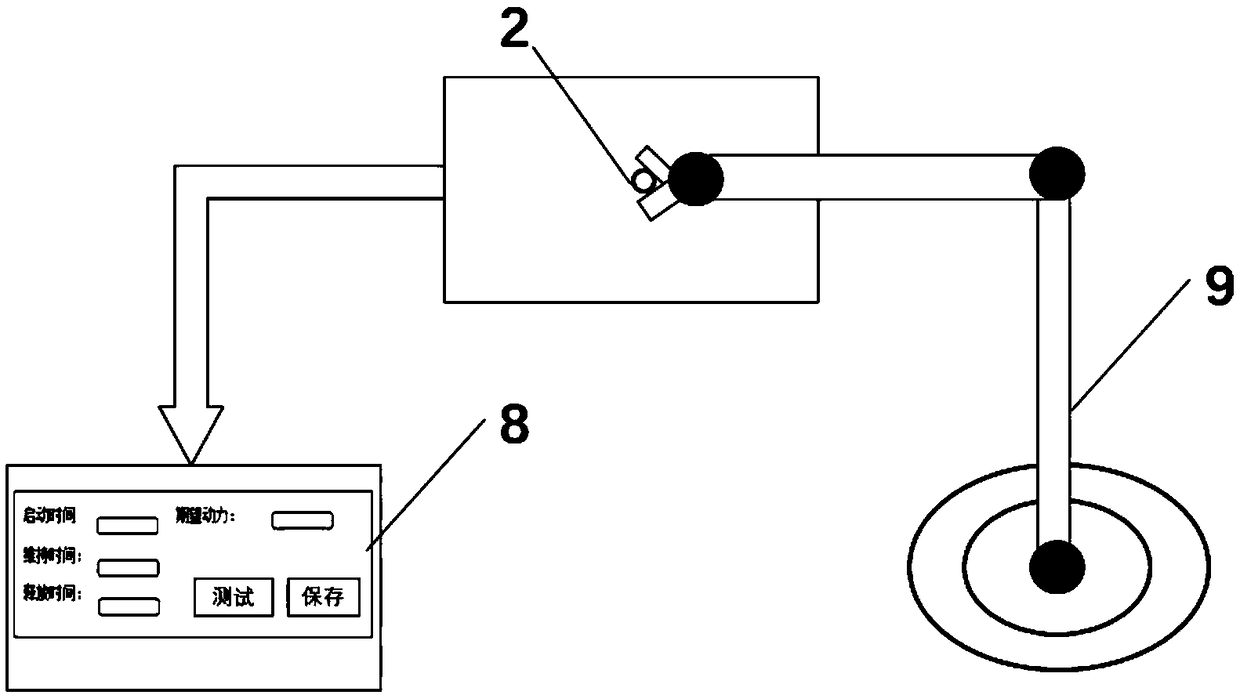

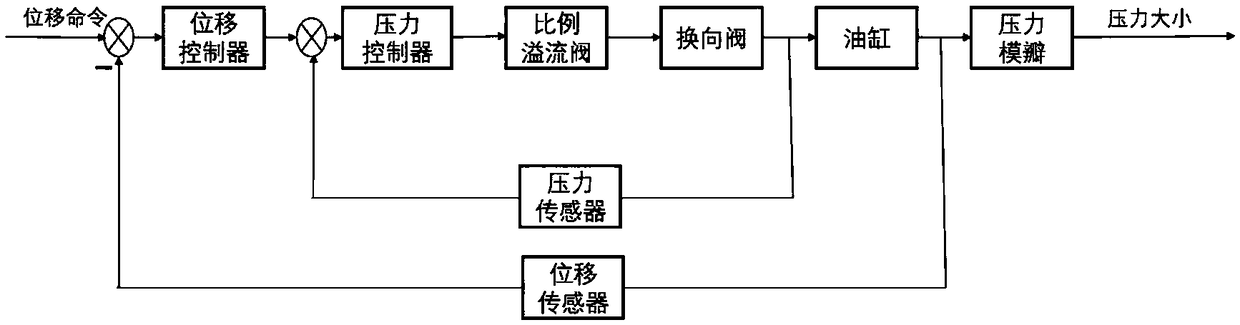

[0023] As shown in the figure, the crimping platform of this embodiment includes a safety box 1, a tight mouth mold part 2, a hydraulic cylinder 3, a photoelectric sensor 4, a pressure sensor 5, a displacement sensor 6, a proportional overflow valve 7 and a manual interactive operation interface 8 and a four-degree-of-freedom loading robot9. The tight-mouth die flap 2 is connected to the hydraulic cylinder 3, the hydraulic cylinder 3 is connected to the oil tank outside the crimping platform, and a proportional overflow valve 7 is set on the connected oil inlet and outlet pipelines, and the man-machine interaction interface 8 is displayed through the The uprights are connected to the safety box.

[0024] Specifically, the four-degree-of-freedom loading robot unit accepts the detonating cord with the metal sleeve manually installed, and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com