Necking-down spinning numerical-control forming equipment for corrugated pipe type thin-walled parts

A technology for thin-walled parts and forming equipment, which is applied to the necking and spinning device for thin-walled pipe parts and large-scale fields. Eliminate hidden quality risks, reduce the length of circumferential welds, and eliminate the effects of longitudinal welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

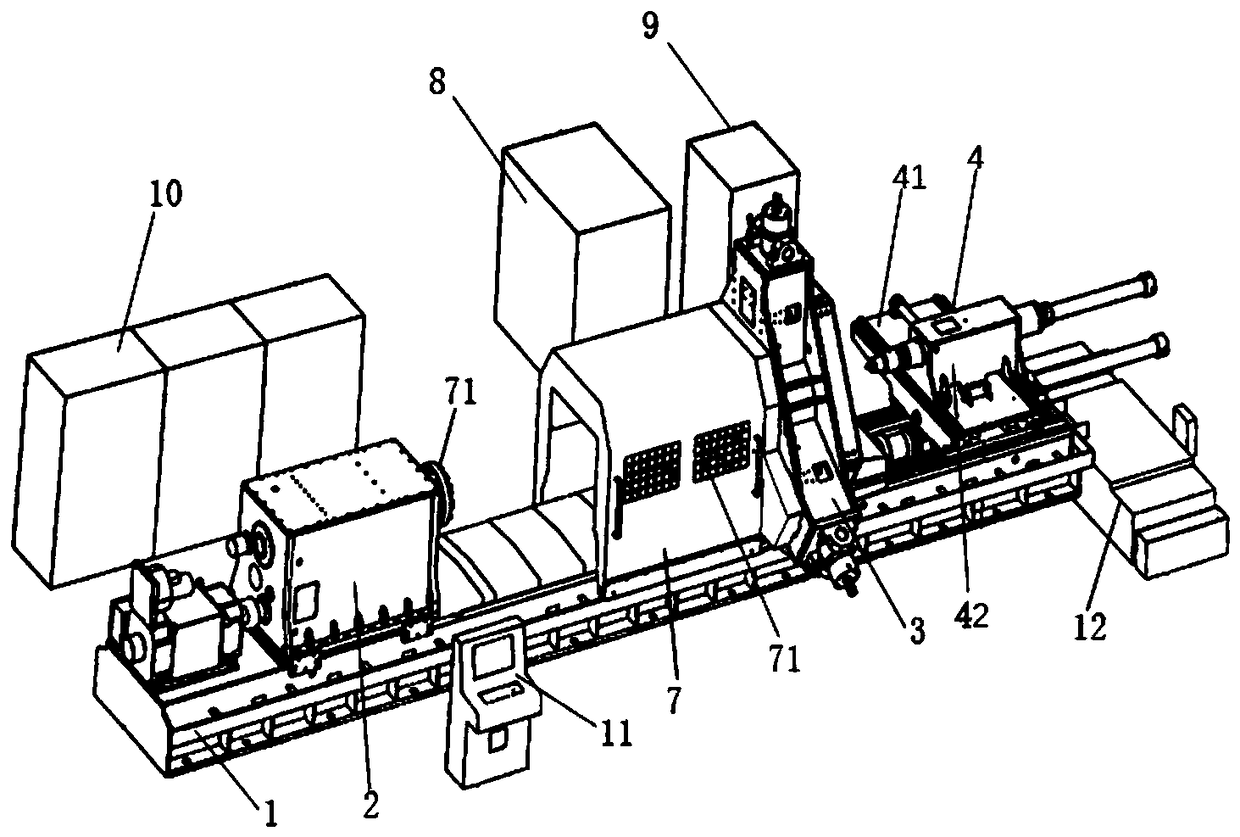

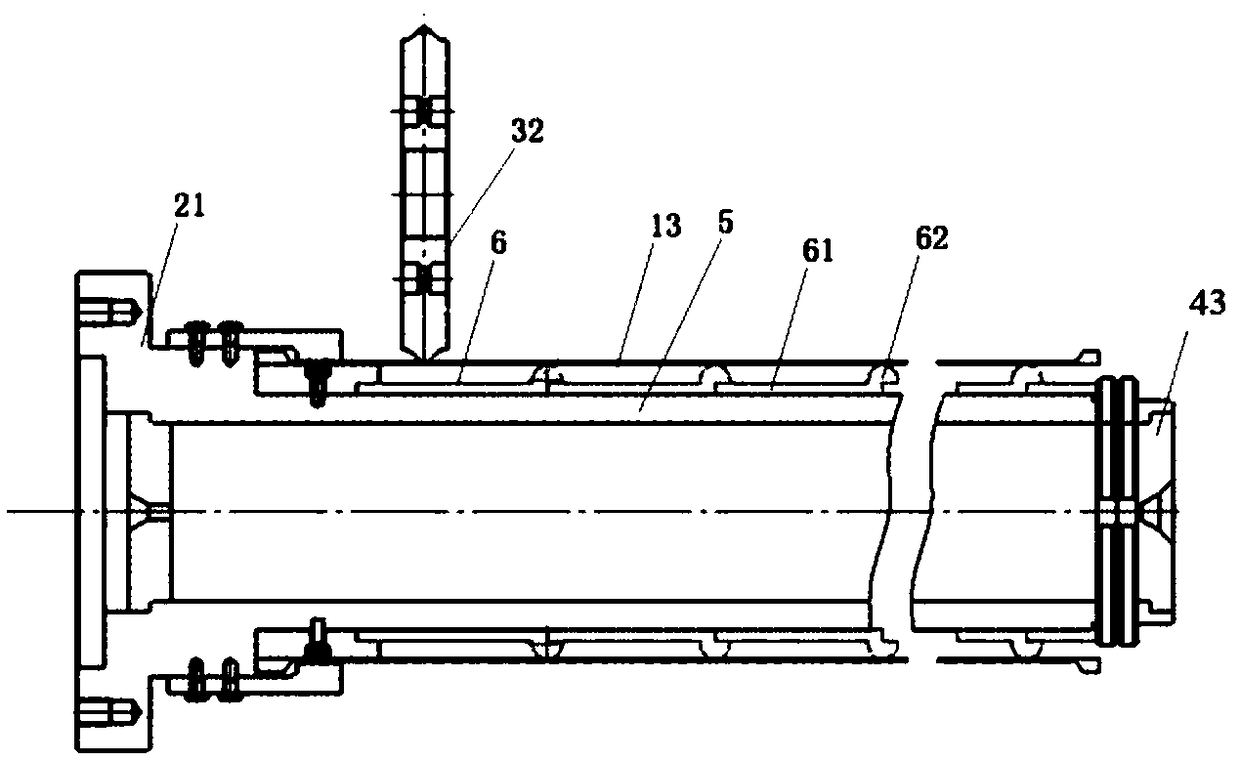

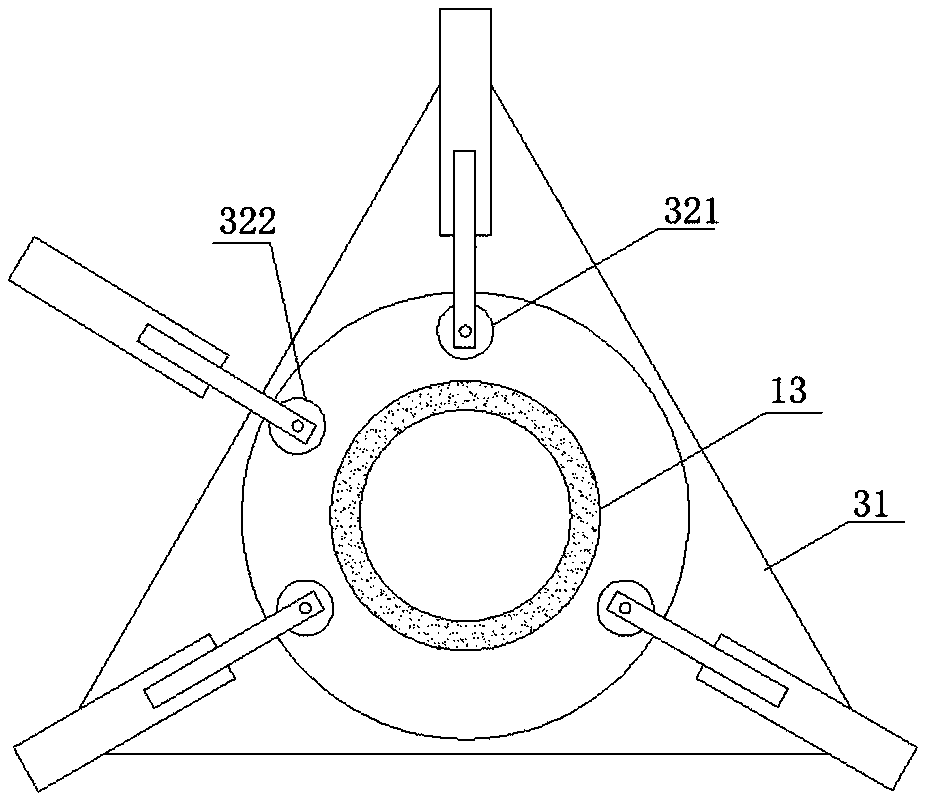

[0023] Such as figure 1 , 2 As shown, this embodiment provides a corrugated tube-like thin-walled parts necking and spinning numerical control forming equipment, including a machine tool 1, a spindle device 2, a rotary wheel 32 device 3, a tail top device 4, and a spindle arranged in sequence on the machine tool 1. A core mold 5 and a corrugated mold 6 sleeved outside the core mold 5 are arranged between the device 2 and the tail top device 4; wherein the rotating wheel 32 device 3 includes a rotating wheel 32 frame 31 and a rotating wheel 32, the rotating wheel 32 device 3 and the machine tool 1 Sliding connection and servo movement between the spindle device 2 and the tail top device 4; a processing area is set on the rotating wheel 32 frame 31, one end of the core mold 5 is connected to the spindle 21 in the spindle device 2, and the corrugated mold 6 passes through the rotating The processing area on the wheel 32 frame 31 is connected with the tail top device 4; the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com