A paint spraying device for building construction

A technology of building construction and spraying device, applied in spraying device, liquid spraying device, construction and other directions, can solve the problems of uneven spraying and user inconvenience, and achieve the effect of ensuring spraying quality, stirring evenly, and avoiding deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

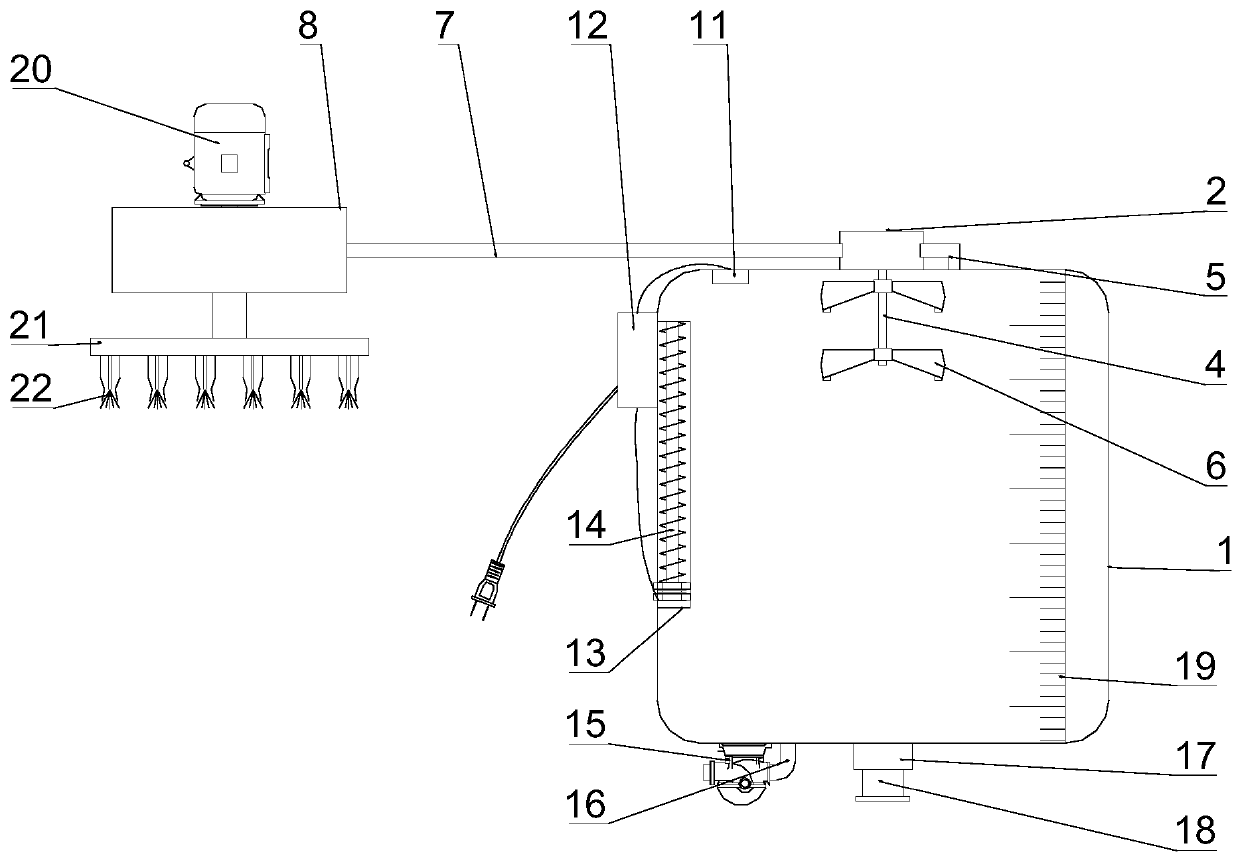

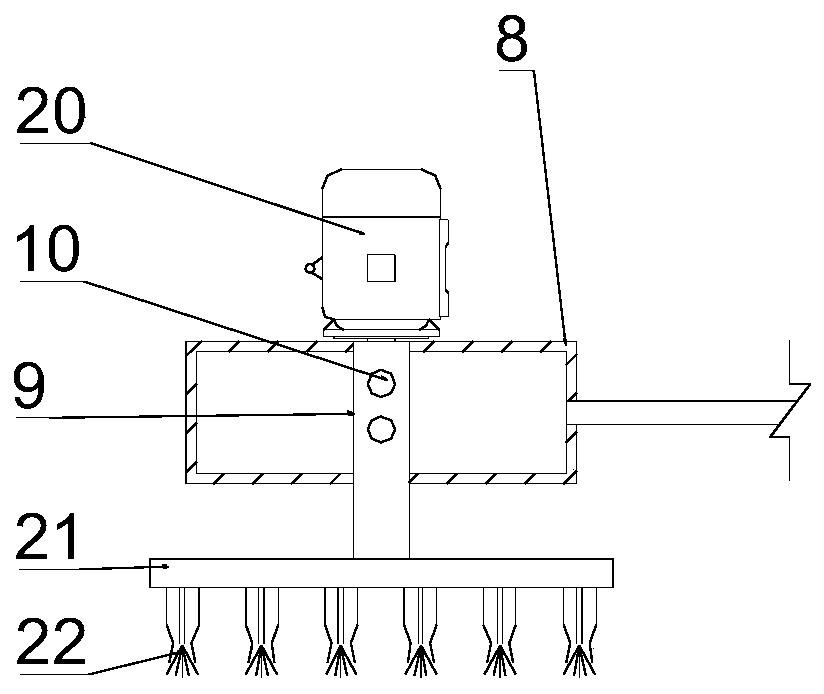

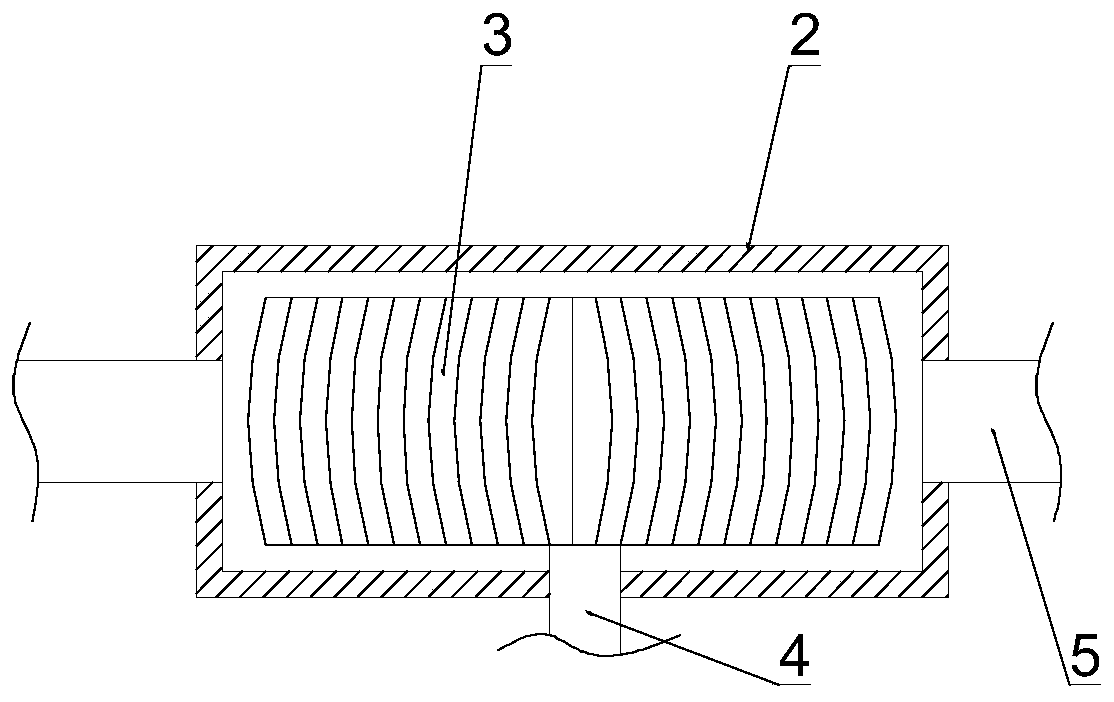

[0026] A kind of paint spraying device for building construction, please refer to figure 1 and 2 , comprising a paint tank 1, the upper part of the paint tank 1 is fixedly connected with a housing 2, the inside of the housing 2 is provided with a rotating wheel 3, and the mounting hole of the rotating wheel 3 is fixedly connected with a wheel that is rotatably connected with the side wall of the housing 2 Rotating cylinder 4, rotating cylinder 4 extends to the inside of paint tank 1 and several turning plates 6 are installed on rotating cylinder 4, one side of the inside of housing 2 passes through intermediate pipeline 5 and the inner upper part of paint tank 1 Connected, the other side of the inside of the housing 2 is connected with a hose 7, a negative pressure pump 15 is installed on the bottom of the paint tank 1, and the gas outlet of the negative pressure pump 15 is connected to the inside of the paint tank 1 through a communication pipe 16. The side phase is connecte...

Embodiment 2

[0029] On the basis of Example 1, please refer to figure 1 and 3 , the lower side wall of the paint tank 1 is fixedly connected with a supplementary pipeline 17, the inner wall of the supplementary pipeline 17 is bonded with a soft rubber layer, and a sealing rod 18 is movable embedded in the soft rubber layer, and the negative pressure pump 15 is equipped with a power cord and The switch, the paint box 1 is made of transparent material, and the display scale value 19 is printed on the paint box 1, and the upper wall of the housing 2 is respectively equipped with sealed bearings, and the rotating cylinder 4 is installed in the mounting hole of the sealed bearing, and the upper wall of the paint box 1 A temperature sensor 11 is installed on the side inner wall, a ceramic body 13 is fixedly connected to the side wall of the paint box 1, a heater 14 is installed in the ceramic body 13, a PLC controller 12 is installed on the surface of the paint box 1, and the diameter of the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com