Environment-friendly flue gas desulfurization treatment device

A treatment device and an environment-friendly technology, which is applied in the field of environment-friendly flue gas desulfurization treatment devices, can solve problems such as the threat to the operation safety of environmental protection facilities, increase the construction cost of environmental protection facilities, and increase the height of desulfurization towers, achieving obvious homogenization effect and improving Homogenization effect, effect of avoiding deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

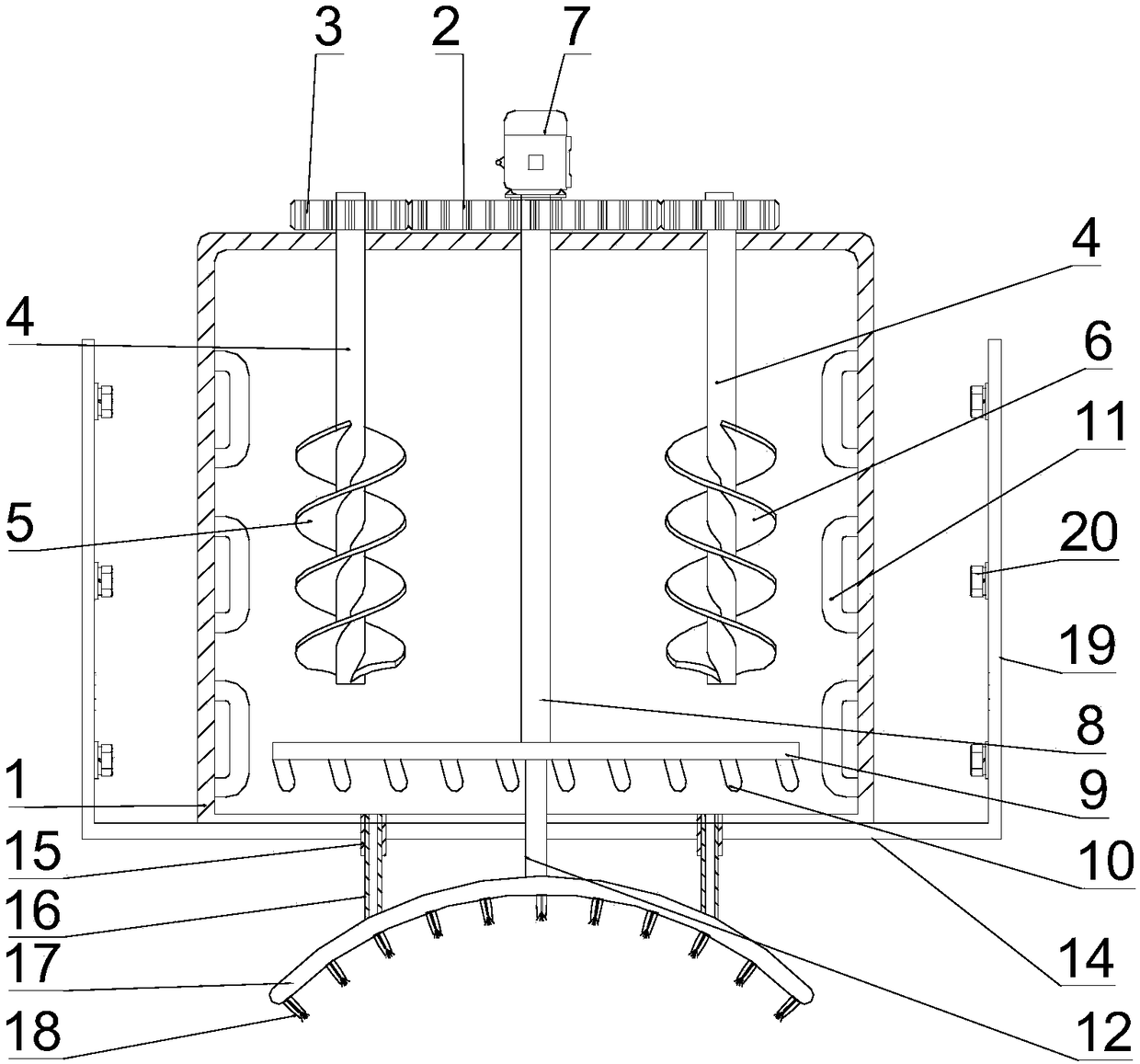

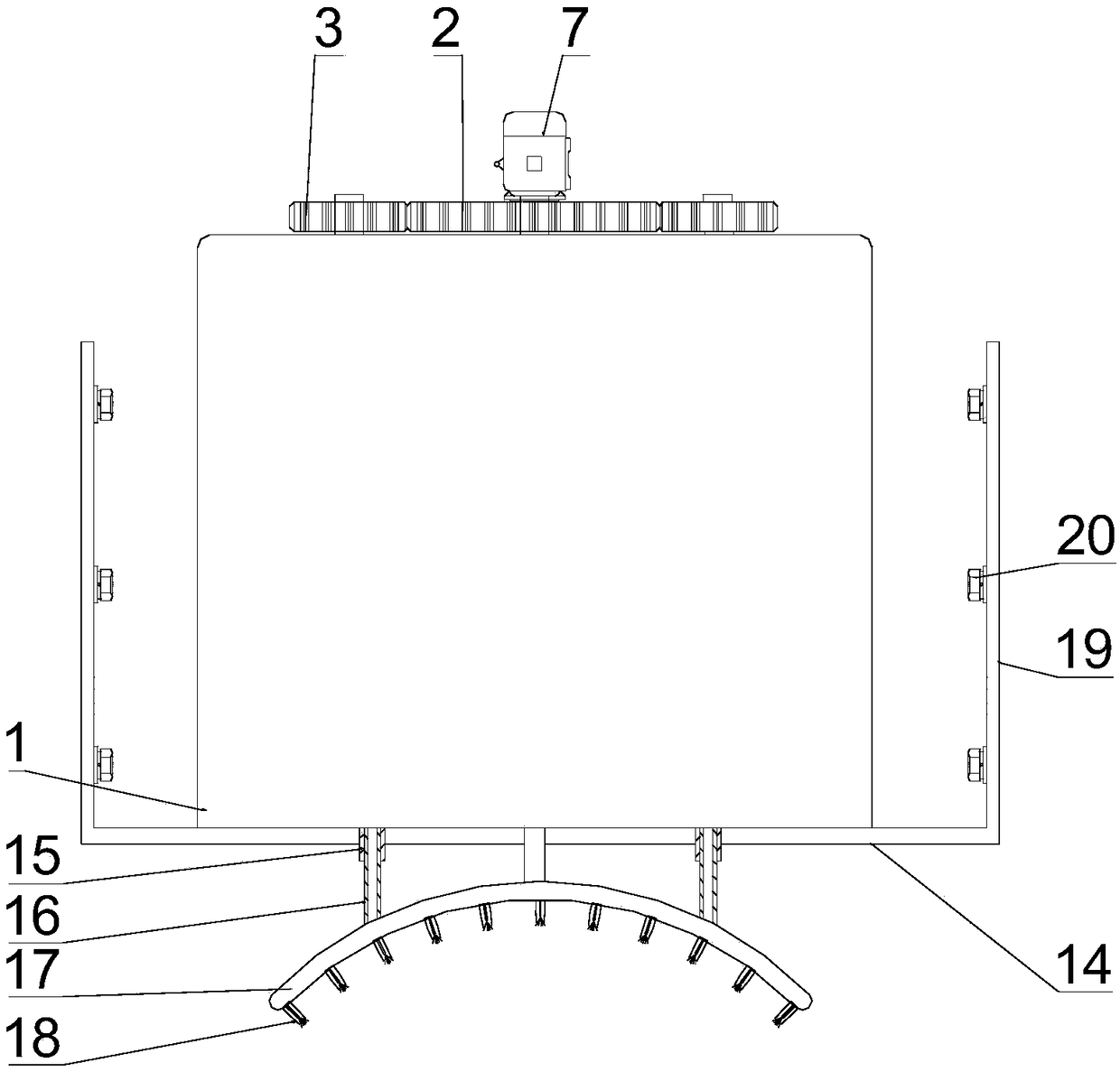

[0018] see figure 1 , an environment-friendly flue gas desulfurization treatment device, comprising a mounting plate 14, the two ends of the mounting plate 14 are respectively fixedly connected with a mounting plate 19, the mounting plate 19 is equipped with a plurality of expansion bolts 20, the upper part of the mounting plate 14 is fixed It is connected with an alkaline adsorption solution box 1, and the alkaline adsorption solution box 1 is equipped with an alkaline adsorption solution. The upper side of the alkaline adsorption solution box 1 is provided with a driving gear 2, and the left and right sides of the driving gear 2 are meshed and connected with two A driven gear 3, the mounting hole of the driven gear 3 is fixedly sleeved with a stirring shaft 4 extending into the alkaline adsorption solution tank 1, and the stirring shaft 4 is rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com