Ferro-nickel phosphate/carbon nanotube composite material and preparation method and application thereof

A carbon nanotube composite and carbon nanotube technology, applied in the field of electrochemistry, can solve problems such as the agglomeration of nickel-iron phosphide nanoparticles, achieve good electrical conductivity, avoid accumulation, and solve the effects of severe agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The nickel-iron phosphide / carbon nanotube composite material was synthesized according to the following steps, which was denoted as Ni-Fe-P / CNT (1).

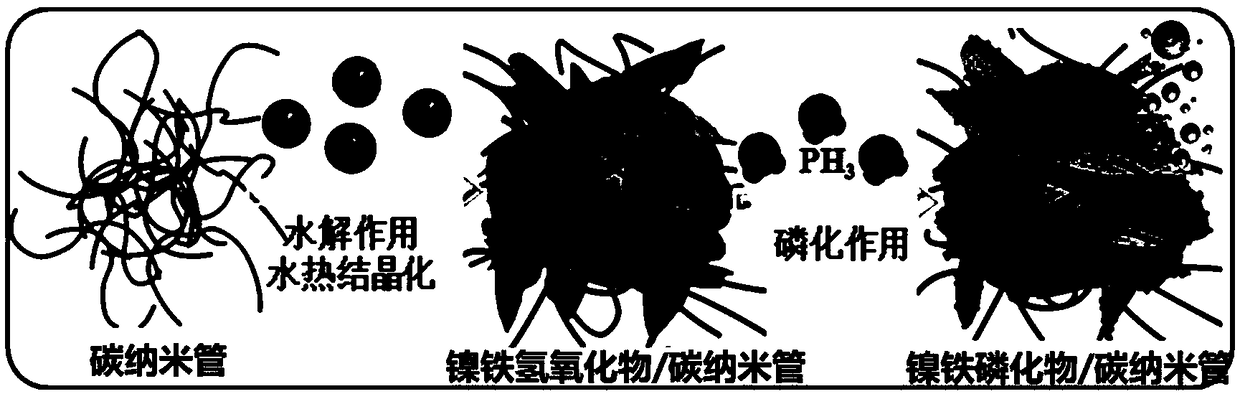

[0045] The preparation process is as figure 1 shown, including the following steps:

[0046] (1) Pretreatment of carbon nanotubes: cleaning and removing residual impurities on the surface of carbon nanotubes, and generating a large number of defects and oxygen-containing surface functional groups on the surface of carbon nanotubes by acid treatment;

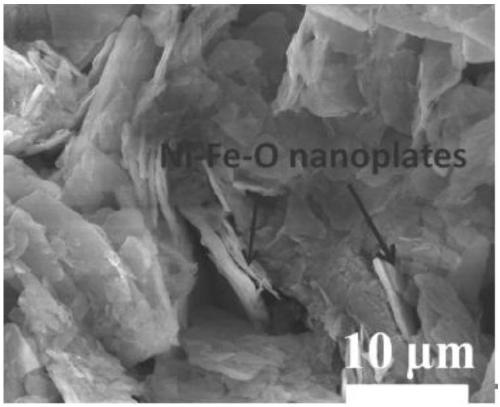

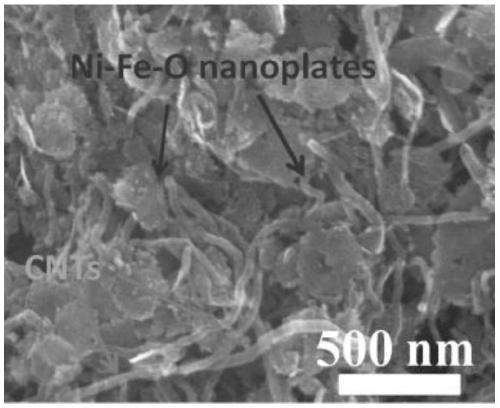

[0047] (2) Preparation of nickel-iron hydroxide / carbon nanotube composite precursor: ultrasonically disperse the carbon nanotubes pretreated in step (1) in nitrogen, nitrogen-dimethylformamide solution; add nickel salt and iron After salt and stirring, an oil bath is used to obtain a stable three-dimensional structure nickel-iron hydroxide / carbon nanotube composite precursor through three heating reactions;

[0048] (3) In-situ conversion preparation of nickel-iron phosphi...

Embodiment 2

[0055] The nickel-iron phosphide / carbon nanotube composite material was synthesized according to the following steps, which was denoted as Ni-Fe-P / CNT (2).

[0056] (1) The pretreatment of carbon nanotubes specifically includes: dissolving 50 mg of carbon nanotubes (CNTs) in 5 mL of acetone, stirring at room temperature for 4 hours, washing and drying. It was added in 150mL of 20% hydrogen peroxide / 5% nitric acid mixed solution (V 双氧水 :V 硝酸 =4:1), after 10 minutes, the temperature was raised to 50°C for 5 hours, washed and dried.

[0057] (2) The preparation of nickel-iron hydroxide / carbon nanotube composite precursor (Ni-Fe LDH / CNT) is as follows: add 10 mg of pretreated carbon nanotubes to 30 mL of nitrogen, nitrogen-dimethylformamide solution ( DMF), ultrasonically dispersed for 20min. Then add 1.92mL of 0.2M nickel nitrate solution and 0.96mL of 0.2M ferric nitrate solution into the above solution, stir and react at room temperature for 3min, use an oil bath, heat up to...

Embodiment 3

[0062] The nickel-iron phosphide / carbon nanotube composite material was synthesized according to the following steps, which is denoted as Ni-Fe-P / CNT (3).

[0063] (1) The pretreatment of carbon nanotubes specifically includes: dissolving 200 mg of carbon nanotubes (CNTs) in 10 mL of acetone, stirring at room temperature for 5 hours, washing and drying. It was added in 250mL of 30% hydrogen peroxide / 10% nitric acid mixed solution (V 双氧水 :V 硝酸 =4:1), after 30min, the temperature was raised to 70°C for 3h, washed and dried.

[0064] (2) The preparation of nickel-iron hydroxide / carbon nanotube composite precursor (Ni-Fe LDH / CNT) is as follows: add 20 mg of pretreated carbon nanotubes to 40 mL of nitrogen, nitrogen-dimethylformamide solution ( DMF), ultrasonically dispersed for 50min. Then add 4.8mL of 0.2M nickel nitrate solution and 0.96mL of 0.2M ferric nitrate solution into the above solution, stir and react at room temperature for 10min, use an oil bath, heat up to 100°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com