Preparation of Supported Ruthenium-Based Hydrogenation Catalyst and Its Application in Catalytic Hydrogenation of Butenedioic Anhydride

A hydrogenation catalyst and a supported technology are applied in the field of preparation of a supported ruthenium-based hydrogenation catalyst, which can solve the problems that the ruthenium-based catalyst has not made a great breakthrough, and the activity and selectivity need to be improved, and achieve high stability and cost. Low, reduced effect on mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

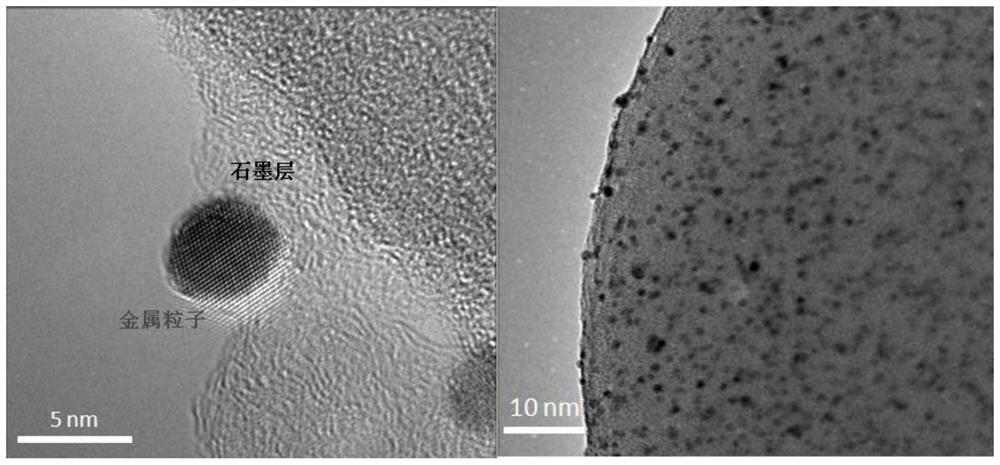

Method used

Image

Examples

Embodiment 1

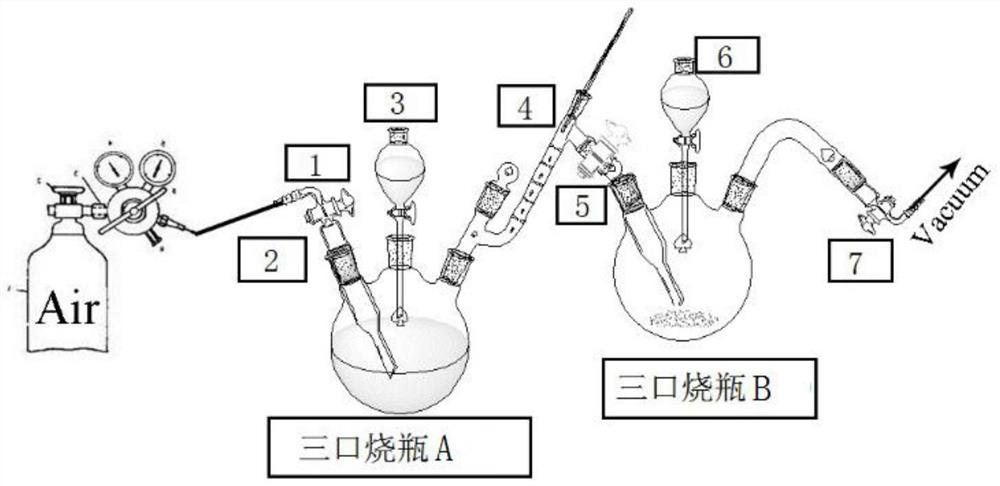

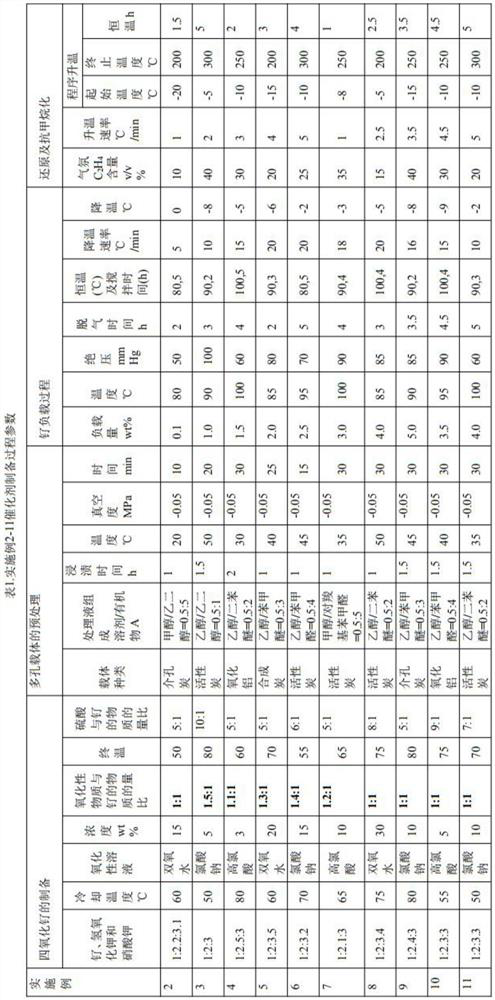

[0044] A ruthenium-based hydrogenation catalyst having a ruthenium load is configured. The specific process is as follows:

[0045] 1) The ratio of ruthenium, potassium hydroxide and potassium hydroxide and potassium hydroxide were added to the crucible in the ratio of 1: 2.1: 3.2, and fired at 650 ° C to melt 1 h. Then it was added to 80 ° C to add an appropriate amount of hot water, stir until all solids dissolved.

[0046] 2) Pour the solution prepared in the three flask A and dropped into 15 wt% sodium hypochlorite solution by the funnel, and the amount of sodium hypochlorite is 1.5 times the amount of ruthenium. Then the temperature is warmed to 80 ° C, stirred, and the reaction is slowly added from the funnel from the funnel from the funnel for about 30 minutes. At this time, there will be a golden quadruple hydrazine gas.

[0047] 3) Weigh activated carbon corresponding to 5% load (France Arkema Ceca (3SW, Particle Size: 250-300MESH, N) 2 -BET: 980M 2 G -1 ASH Content: <3%)...

Embodiment 12

[0066] 100 g of butene hydrogenlide, 200 ml DMF and 5G Example 1 was put into high pressure hydrogenation reactor, and the reaction kettle was sealed. After replacing the air, the hydrogen was charged and stirred, at a temperature of 120 ° C, hydrogen pressure Catalytic hydrogenation reaction was carried out under the conditions of 1.0 MPa. Pre-reactions and in progress, in real time, the hydrogen-hydrogen-mixed pH is monitored online, ensuring that the hydrogen solution in the kettle is maintained at 7.5 to 8.0, and real-time regulation is carried out by the concentrated juice of the tea. After the hydrogen is not suction, the in-line sampling analysis, the reactant in the hydrogenation liquid is stopped and the reaction is stopped to obtain butoth dihydrane. The reaction time was 30 minutes, the conversion rate was 100%, and the selectivity was 99.1%.

Embodiment 13

[0068] 100 g of butene hydrogen-hydrogenation catalysts of 100 g of butene chloric anhydride, 100 mL DMF and 1G Example 6 were put into high pressure hydrogenation reactor, and the reactor was sealed. After the air was replaced, the hydrogen was charged, and the temperature was 90 ° C, the hydrogen pressure was Catalytic hydrogenation reaction was carried out under 2.0 MPa conditions. Pre-reactions and in progress, real-time online pH, ensure that the hydrogen solution in the kettle is maintained at 7.5 to 8.0, and real-time regulation is carried out by linkage of Ruoya lobes. After the hydrogen is not suction, the in-line sampling analysis, the reactant in the hydrogenation liquid is stopped and the reaction is stopped to obtain butoth dihydrane. The reaction time was 35 minutes, the conversion rate was 100%, and the selectivity was 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com