Gel forming method for sucralfate gel having particle size of 100-500 nm

A technology of sucralfate and particle size, which is applied in the direction of pharmaceutical formulations, organic active ingredients, and inorganic ineffective ingredients, etc., can solve problems such as fluidity that cannot meet oral needs and drug efficacy, and achieve strong adhesion and long-term Adhesion time, effect of protection destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0013] Orthogonal experiment

[0014] Table 1. Average particle size (nm) when controlling N to 0.010 / min

[0015]

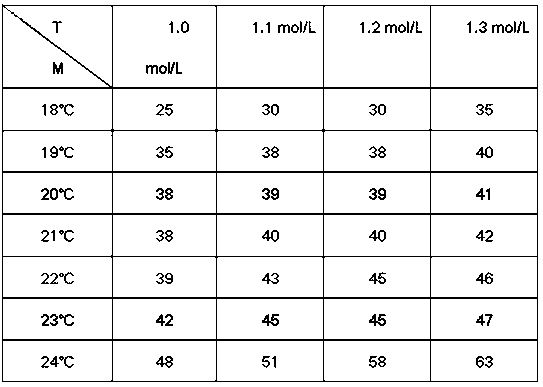

[0016] Table 2. Average particle size (nm) when controlling N to 0.011 / min

[0017]

[0018] Table 3. Average particle size (nm) when controlling N to 0.012 / min

[0019]

[0020] Table 4. Average particle size (nm) when controlling N to 0.013 / min

[0021]

[0022] As can be seen from Experimental Example 1, three key control parameters for sucralfate gelling have been determined through orthogonal experiments, namely temperature (T), sodium hydroxide concentration (M), flow rate and ratio of bottom material volume (N), When T is 19-23°C, M is 1.1-1.2mol / L, and N is 0.011-0.012 / min, the gelled particle size of sucralfate will be 100-500nm.

Embodiment 1

[0024] A kind of particle diameter is the gelation method of the sucralfate gel of 100nm-500nm, comprises the following steps:

[0025] (1) Ingredients: Prepare the required materials according to the formula, including sucralfate, concentrated hydrochloric acid, sodium hydroxide, sodium chloride, essence and preservatives;

[0026] (2) Dissolution: suspend sucralfate in purified water, add concentrated hydrochloric acid and stir, and sucralfate will dissolve into a clear solution in a strong acid environment;

[0027] (3) Gelling: Control the temperature at 19-23°C, add sodium hydroxide aqueous solution with a concentration of 1.1-1.2mol / L into the tank at a certain flow rate, neutralize concentrated hydrochloric acid, and the strong acid environment gradually moves to neutral. When the pH is close to neutral, the solubility of the amphoteric compound sucralfate decreases and is precipitated to form particles with uniform particle size. The ratio of the flow rate of the sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com