Cornea stainer

A technology for dyeing device and cornea, applied in the field of corneal dyeing device, can solve the problems of corneal damage caused by fluorescent dyeing filter paper, easily polluted environment, complicated production process, etc., and achieve the effects of no pollution in the preparation process and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

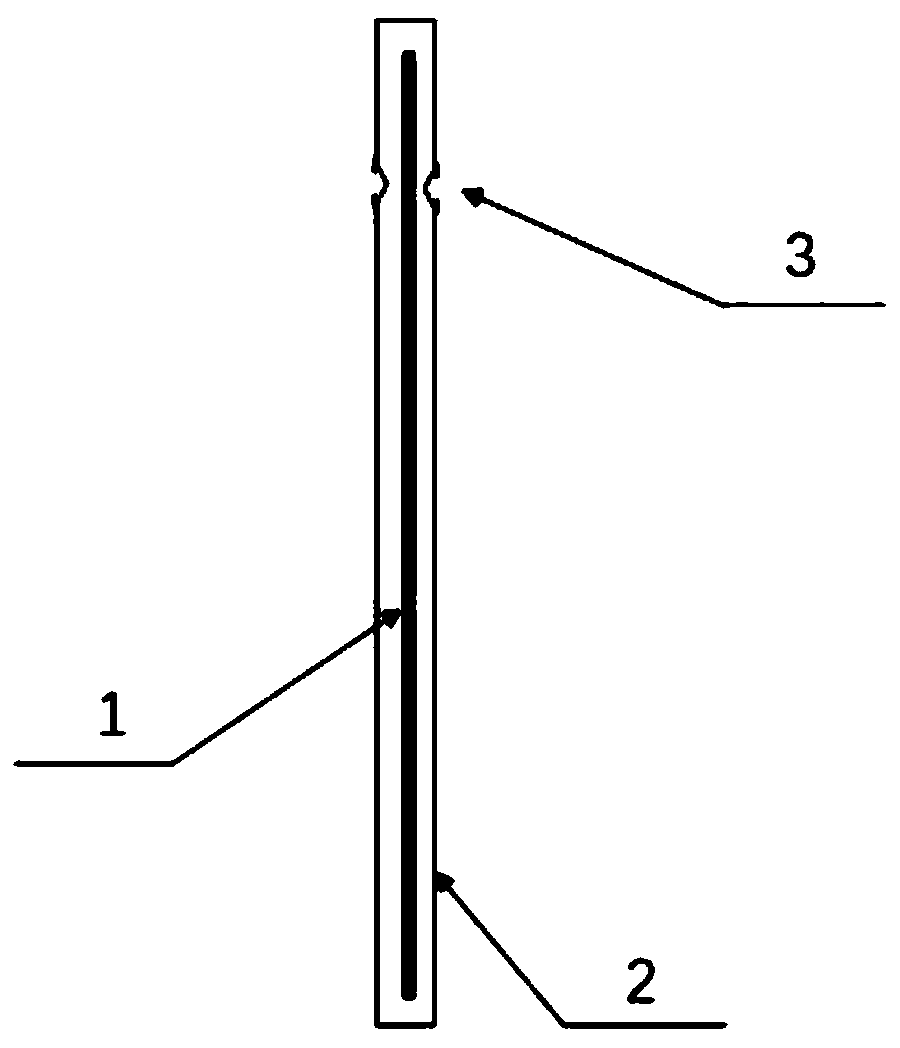

[0033] A corneal dyeing device, comprising a carrier 1 and an encapsulation bag 2, the carrier 1 is cotton yarn or cotton thread, dye A is adsorbed on the carrier 1, and the dye A is sodium fluorescein; the carrier 1 is placed in the bag In the envelope bag 2; The length of described cotton yarn or cotton thread is 6cm. The width of the sealing bag 2 is 0.8cm. One end of the envelope bag 2 is provided with an easy-tear opening 3; the material of the envelope bag 2 is medical sterile dialysis paper.

[0034] The preparation method of this corneal dyer comprises the steps:

[0035] 1), carrier 1 treatment: take cotton yarn or cotton thread, cut into length 6cm;

[0036] 2), the dye A is made into an aqueous solution according to 20g / mL, and placed in a 25cm long water tank, the carrier 1 passes through the water tank and the drying box in turn, the length of the drying box is 2m, and the moving speed of the carrier 1 is 2m / min; The temperature of the drying oven is 150°C;

...

Embodiment 2

[0039] A corneal dyer, comprising a carrier 1 and an encapsulation bag 2, the carrier 1 is cotton yarn or cotton thread, dye A and dye B are adsorbed on the carrier 1, the dye A is sodium fluorescein, and the dye B is Methyl blue; the carrier 1 is placed in the envelope bag 2; the length of the cotton yarn or cotton thread is 5cm. The width of the sealing bag 2 is 0.5cm; one end of the sealing bag 2 is provided with an easy-tear opening 3; the material of the sealing bag 2 is medical sterile dialysis paper.

[0040] The preparation method of this corneal dyer comprises the steps:

[0041] 1), carrier 1 treatment: take cotton yarn or cotton thread, cut into length 5cm;

[0042] 2) Dye A and Dye B were formulated into an aqueous solution at a concentration of 20g / mL, and placed in a 30cm long water tank. The carrier 1 passed through the water tank and the drying oven in sequence. The length of the drying oven was 2m, and the moving speed of the carrier 1 was 2m / mL. min; the te...

Embodiment 3

[0045] A corneal dyer, comprising a carrier 1 and an encapsulation bag 2, the carrier 1 is cotton yarn or cotton thread, dye A and dye B are adsorbed on the carrier 1, the dye A is sodium fluorescein, and the dye B is Placepan blue; the carrier 1 is placed in the envelope bag 2; the length of the cotton yarn or cotton thread is 6cm. The width of the envelope bag 2 is 0.8cm; an easy-tear opening 3 is provided at one end of the envelope bag 2; the material of the envelope bag 2 is medical sterile dialysis paper.

[0046] The preparation method of this corneal dyer comprises the steps:

[0047] 1), carrier 1 treatment: take cotton yarn or cotton thread, cut into length 6cm;

[0048] 2) Dye A and Dye B were formulated into an aqueous solution at a concentration of 20g / mL, and placed in a 30cm long water tank. The carrier 1 passed through the water tank and the drying oven in sequence. The length of the drying oven was 2m, and the moving speed of the carrier 1 was 2m / mL. min; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com