Electronic machine manufacturing device

A technology of machine manufacturing and electronics, which is applied in the field of electronic machine manufacturing devices, can solve problems such as the position change of the reciprocating cylinder, the uneven temperature of the inert gas, and the small size of the miniature reciprocating cylinder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

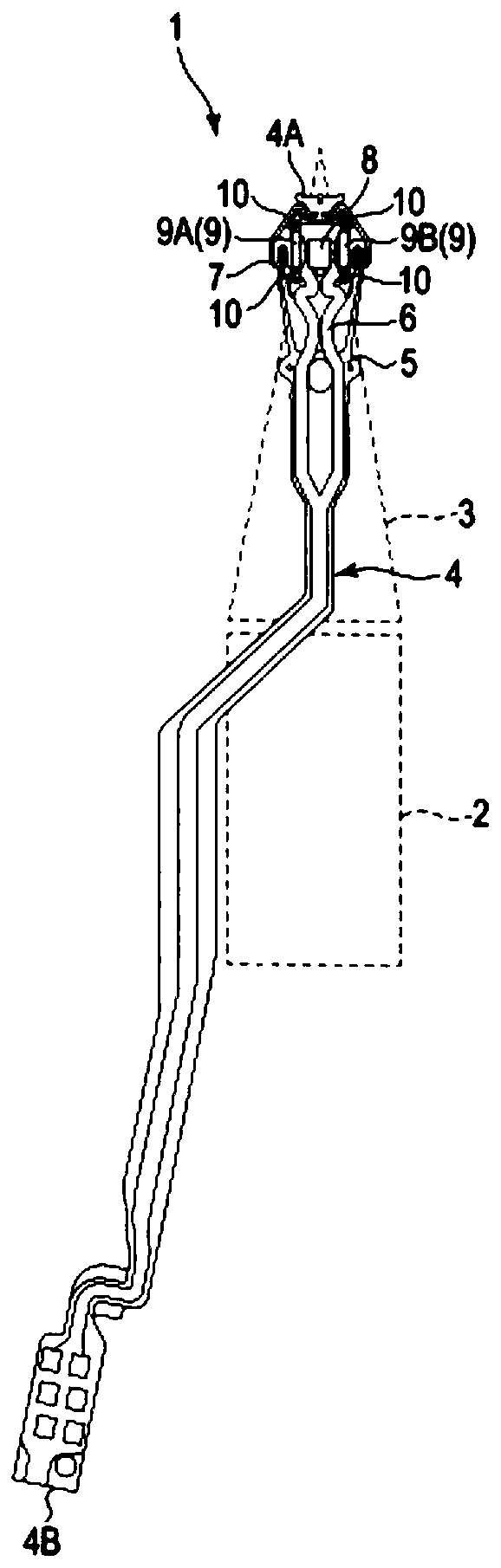

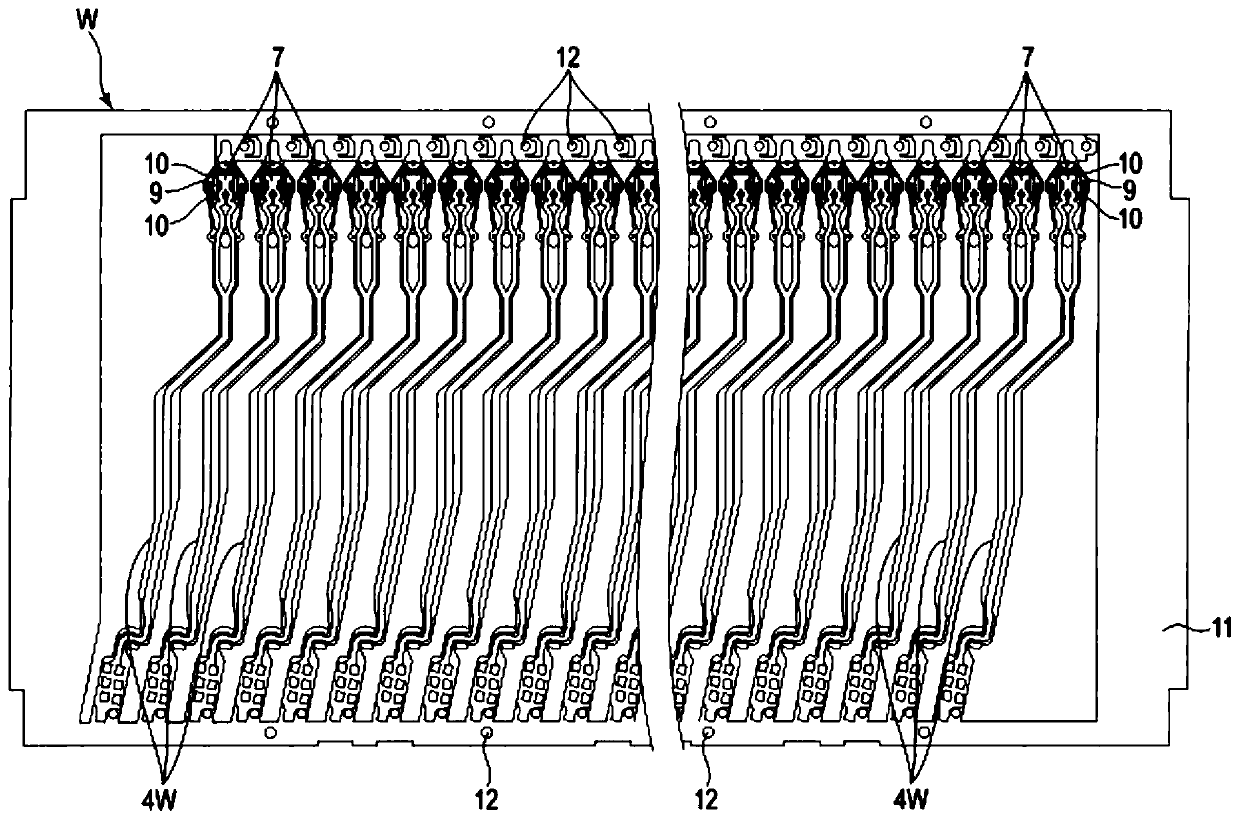

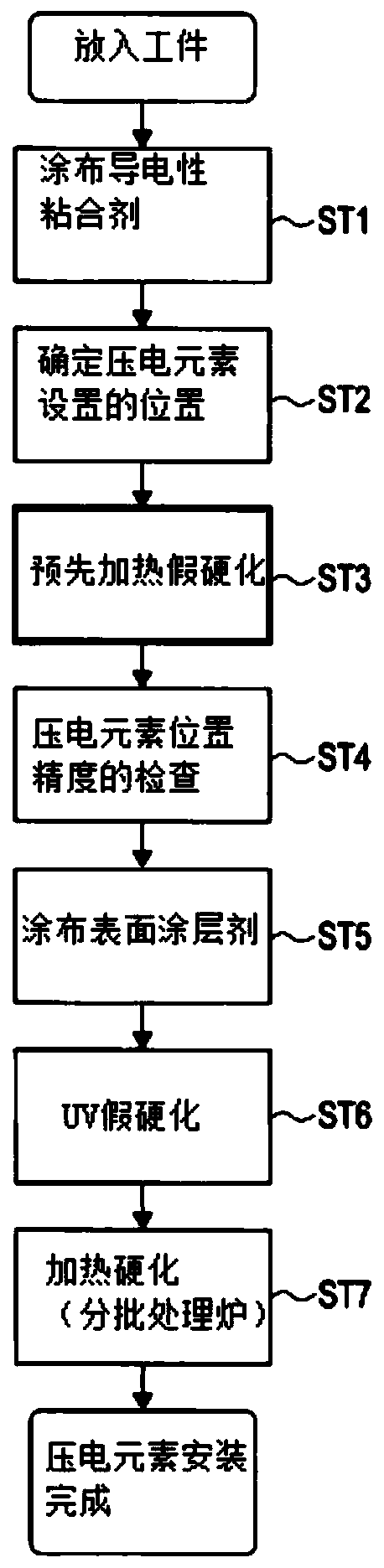

[0022] Refer below Figure 1 to Figure 14 The present invention will be described with respect to the electronic device manufacturing apparatus of the present invention.

[0023] figure 1 It is the suspension 1 of the hard disk drive (HDD) manufactured by the electronic equipment manufacturing apparatus (suspension manufacturing apparatus) 20 of this invention. The hard disk device has a magneto-optical disc that rotates around a main shaft, and a cart that rotates around a fulcrum. arm such as figure 1 The configuration shown is on suspension 1. The suspension 1 has a bottom plate 2 fixed by an arm, a load beam 3 capable of resisting elastic deflection, and a bend 4 of wiring arranged to overlap the load beam 3 .

[0024] The wiring bend 4 includes a metal base 5 composed of a thin stainless steel plate and wiring 6 formed on the metal base 5 . A gimbal portion 7 is formed in the vicinity of the front end 4A of the bend 4 of the wiring, and a slider 8 is mounted on an ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com