Ozone-resistant mildew-proof rubber sealing gasket and construction method thereof

A rubber gasket and ozone-resistant technology, which is applied in the sealing of engines, waterway systems, sewer pipe systems, etc., can solve the problems of poor corrosion resistance of natural rubber gaskets, aging of rubber gaskets, and low service life, so as to reduce maintenance cost, increased service life, and the effect of increased corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

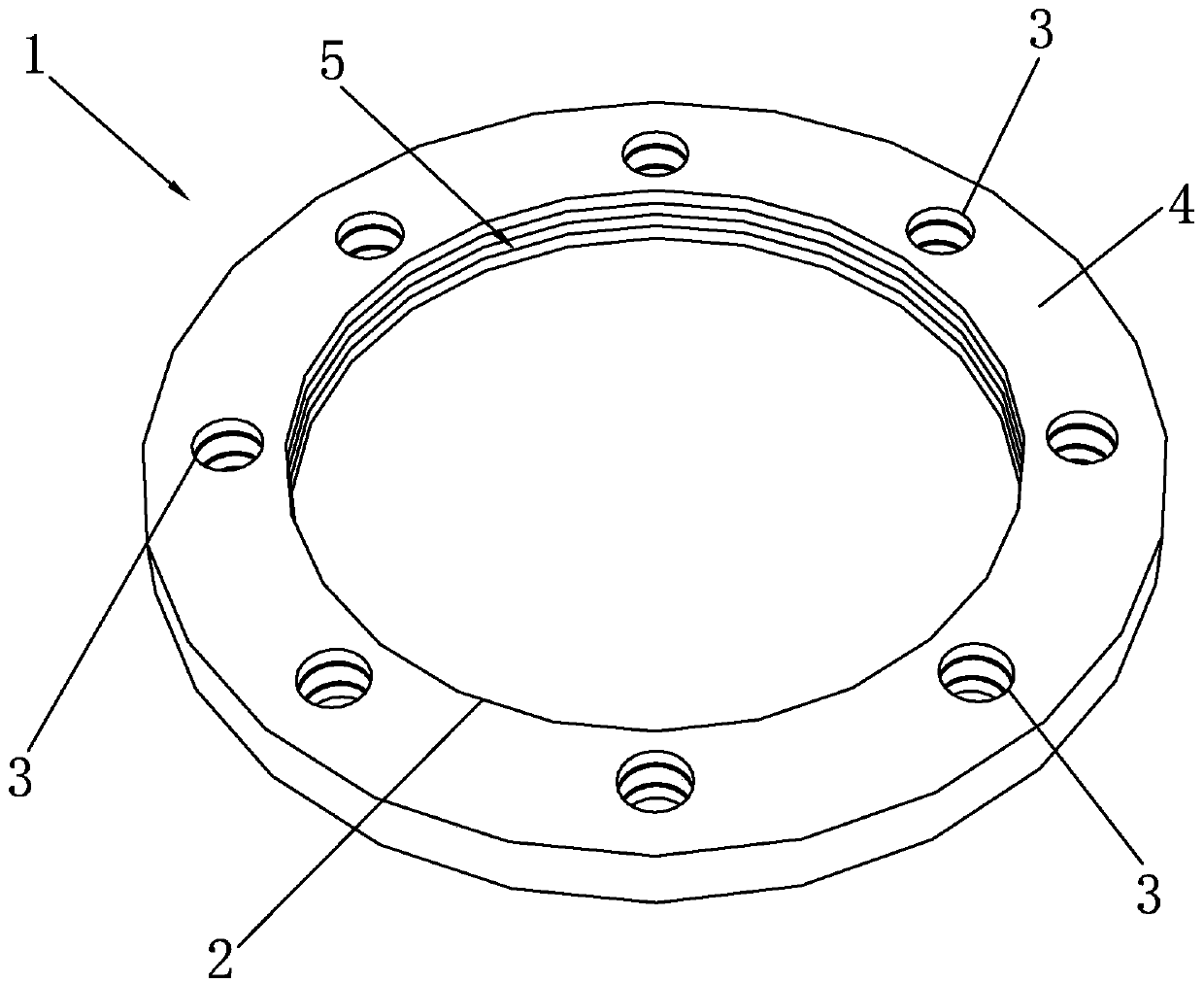

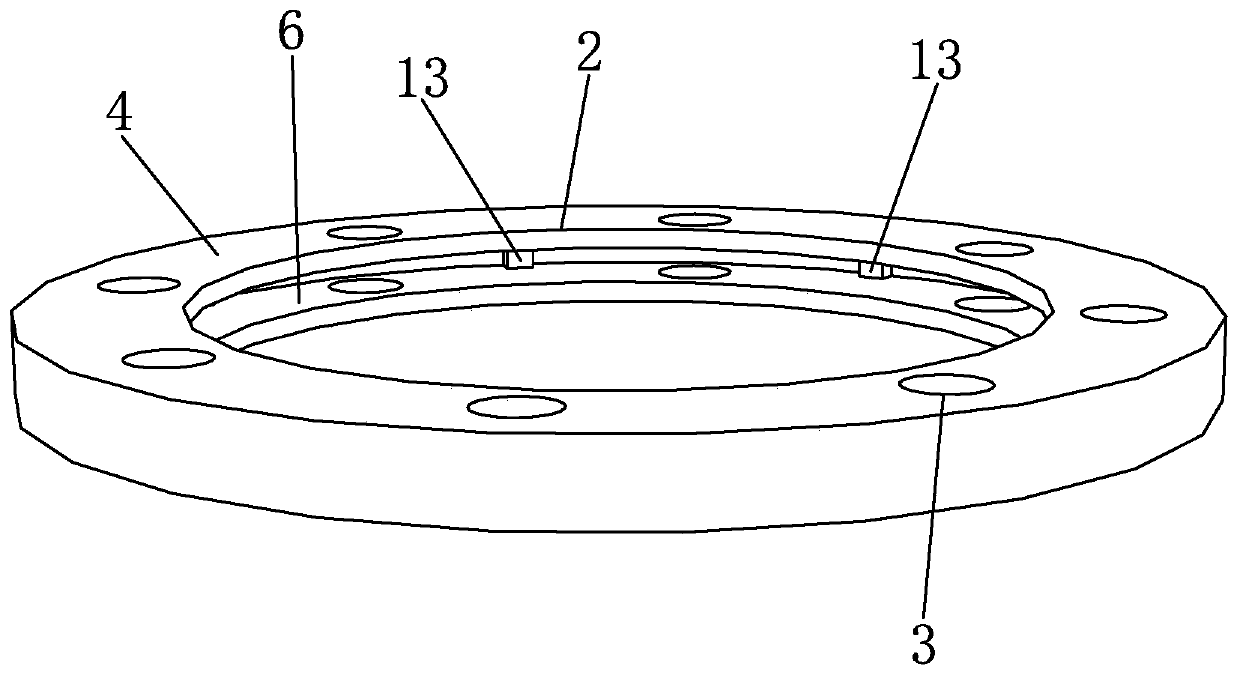

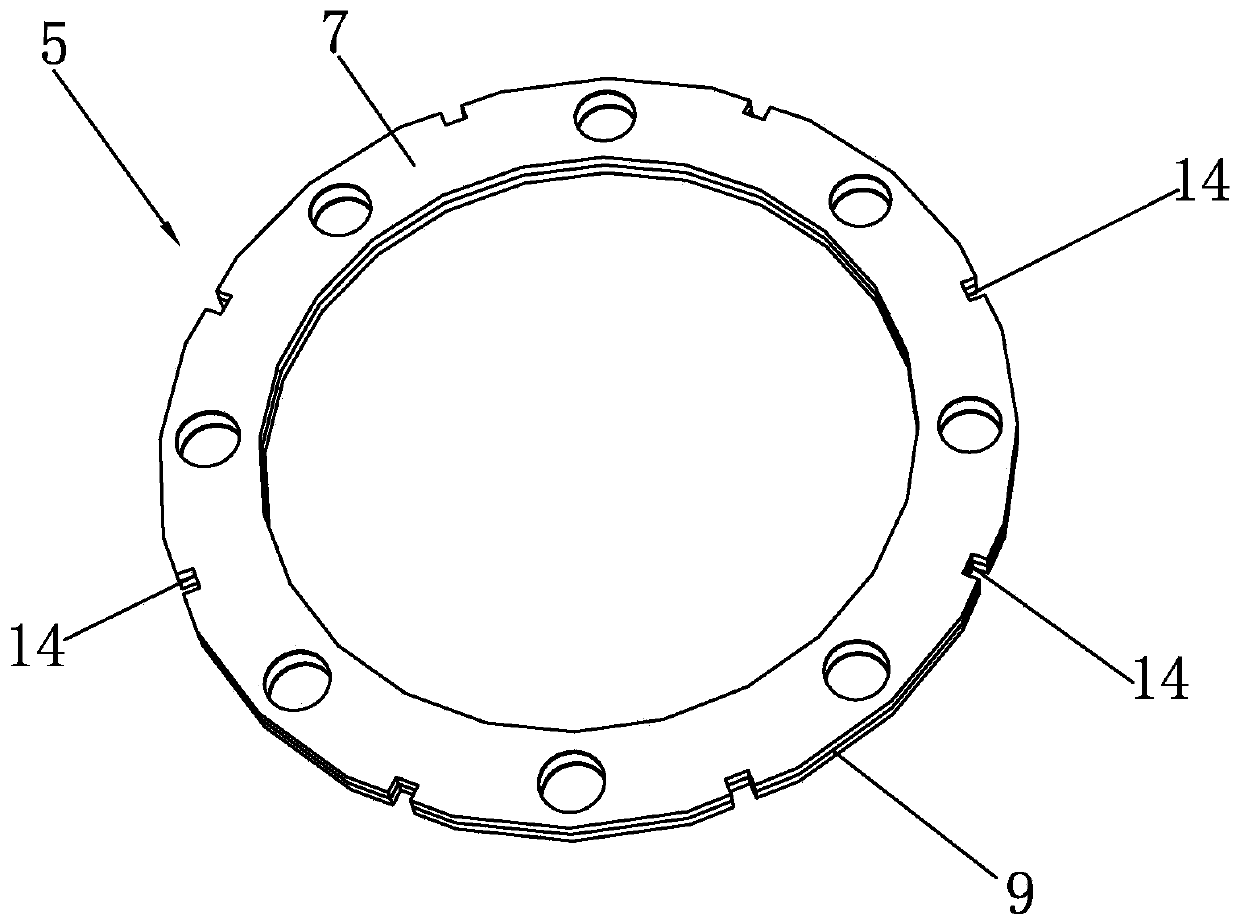

[0053] Such as Figure 1 to Figure 4 As shown, it is an ozone-resistant and mildew-resistant rubber gasket of the present invention, which includes a body 1. The center of the body 1 is provided with a through hole 2, and the circumference of the body 1 is distributed with connection holes 3 passing through the upper and lower ends. The body 1 includes an outer cladding 4. The inner circumference of the inner layer 15 and the outer cladding 4 is provided with an installation cavity 6, the inner inner layer 15 is matched with the installation cavity 6, the inner layer 15 is glued in the installation cavity 6, and the connection holes 3 respectively pass through the outer cladding 4, Embedded layer 15.

[0054] The outer cladding 4 is made of ozone-resistant rubber. Ozone pollution is from the outside to the inside, and the outer cladding layer 4 is made of ozone-resistant rubber, which improves the ozone resistance of the outer cladding layer 4 and avoids ozone pollution on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com