Internal structure of furnace body

A technology of internal structure and furnace body, which is applied to parts, furnaces, and furnace cooling of pumping devices for elastic fluids. It can solve the problems of heavy weight of glass fiber felt, reduced service life of the shell, and difficult installation of the inner tank. Achieve the effect of improving connection strength and stability, ensuring stability and reliability, and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

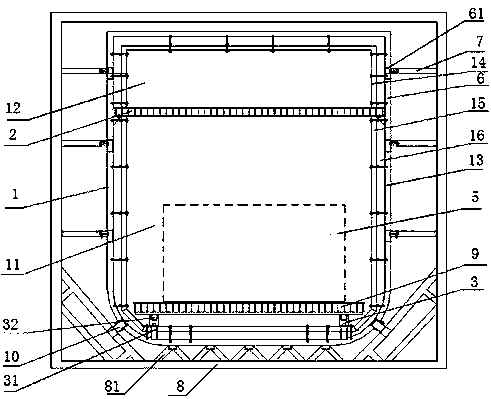

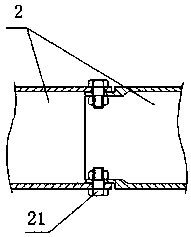

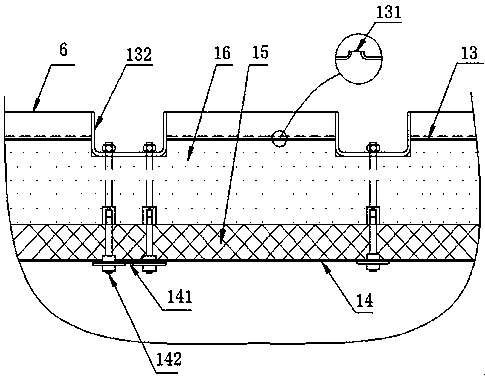

[0048] Such as figure 1 Shown: an internal structure of a furnace body, including an inner tank 1, the cavity of the inner tank 1 is connected with a partition 2, and the partition 2 divides the inner tank into at least two cavities, one of which is a working cavity 11; An inner roller mechanism 3 is arranged in the working chamber 11, and a workpiece 5 is placed on the inner roller mechanism 3; a high-temperature fan is arranged on one side of the inner tank 1.

[0049] The above scheme has the following advantages: (1) By setting the partition plate 2, the working chamber is separated from other chambers, such as the heating chamber, which can avoid the high temperature of the part of the workpiece near the heating body, while the temperature of other parts is low, resulting in The workpiece is heated unevenly; (2) By setting the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com