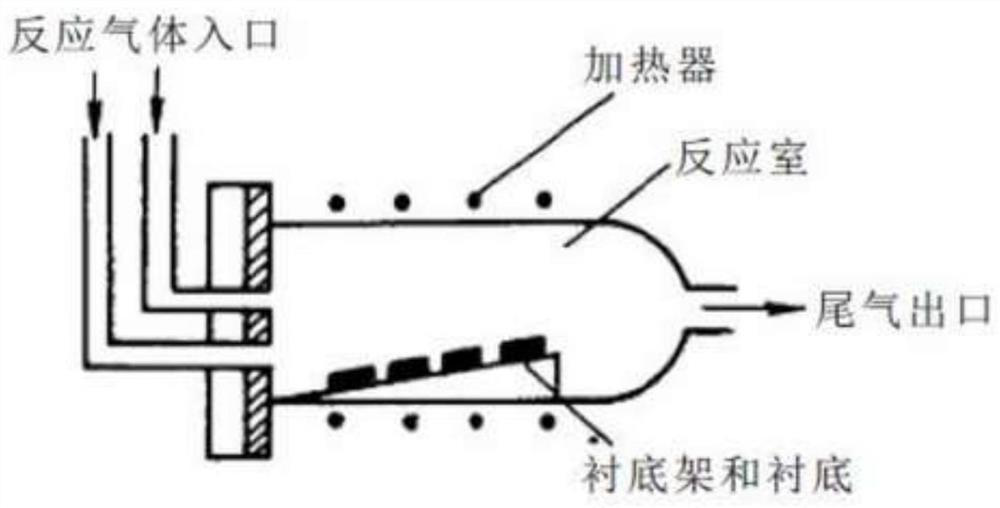

Uniform heating device for vapor deposition and vapor deposition furnace

A technology of uniform heating and vapor deposition, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of slow heating speed, uneven heating, uneven heating of workpiece, etc., to avoid uneven heating, Ensure uniformity and ensure the effect of balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

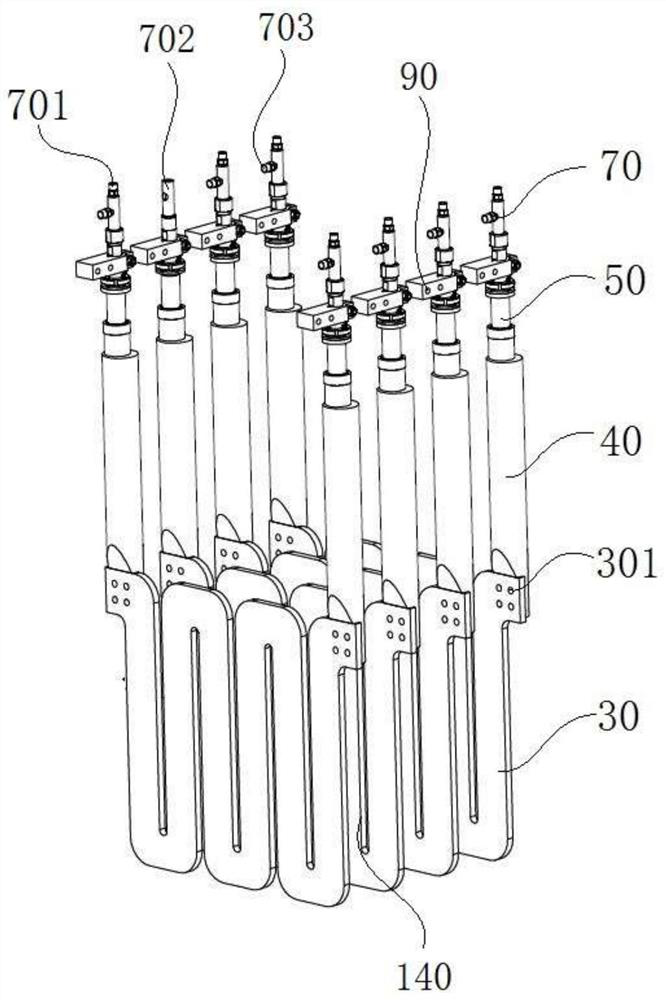

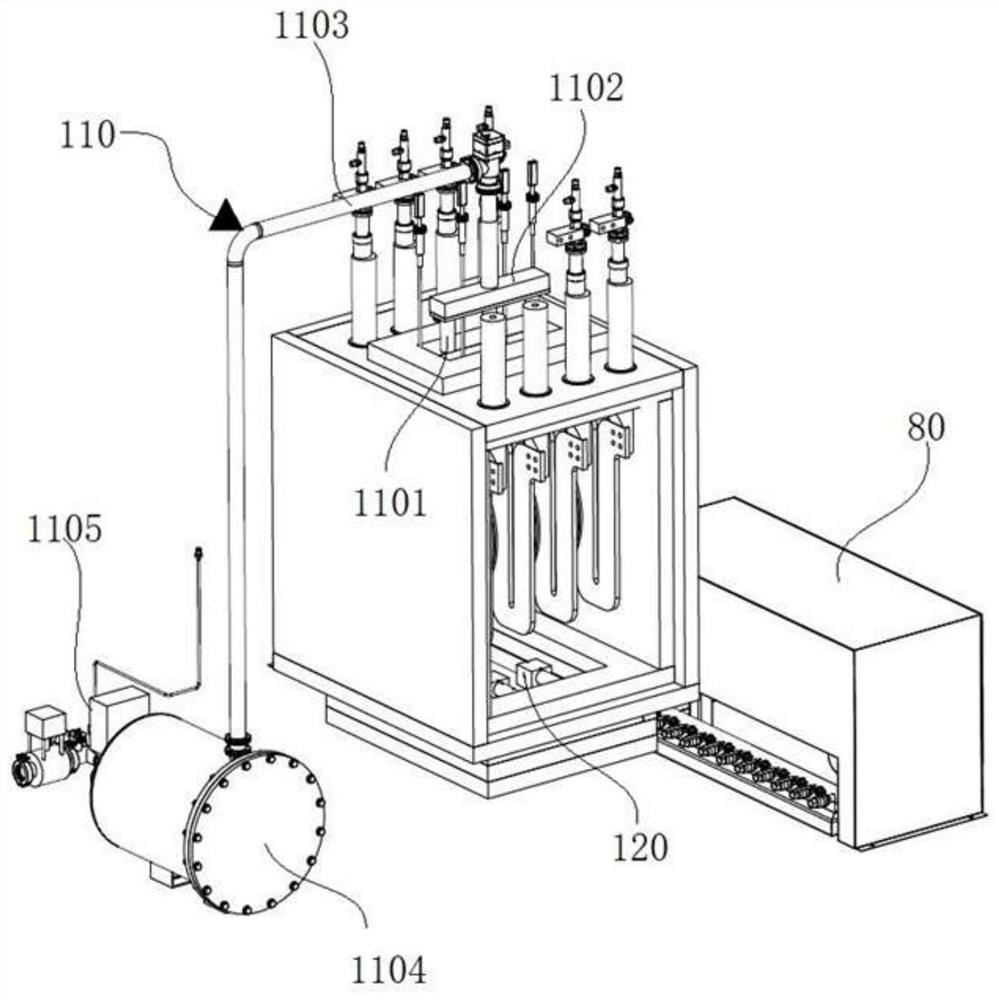

[0044] The invention discloses a uniform heating device for vapor deposition, such as the attached figure 2 As shown, at least two heating plates 30 arranged in gaps are included, and the projections of the heating plates 30 on the same projection plane parallel to them coincide, and the gap between adjacent heating plates 30 forms a heating plate for placing the workpiece 1. Space 140, two ends of each heating plate 30 are respectively connected to a graphite electrode 40, each graphite electrode 40 is connected to a copper electrode 50, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com