Steel pipe offline quenching production device and method

An off-line quenching and production device technology, applied in the direction of quenching device, furnace type, furnace, etc., can solve the problems of limited cooling rate and uniformity, uneven cooling, limited cooling rate, etc., to shorten the time required for water cooling, reduce Rotating equipment wear and effect of reducing furnace time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

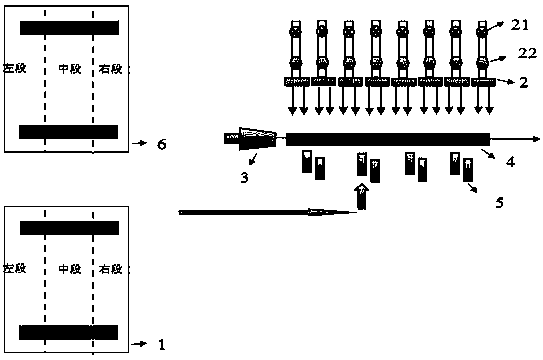

Method used

Image

Examples

Embodiment 1

[0087] The line pipe for marine service of X65QO steel grade is quenched and quenched by external spraying and internal spraying. The outer diameter is 168.3mm and the wall thickness is 15mm. The parameters are set as follows:

[0088] Speed: 90rpm

[0089] Internal spray flow: 418m 3 / h

[0090] External spray pressure: 0.2MPa

[0091] Total flow of external spraying: 1399m 3 / h

[0092] Table 1 The flow density and flow rate of spray boxes in each section

[0093] Tank No.

[0094] Table 2 Full-length properties of steel pipes after quenching

[0095] Maximum Yield Strength MPa

[0096] It can be seen from Table 2 that, by adopting the production device and method for off-line quenching of steel pipes of the present invention, the yield strength and tensile strength fluctuations of line pipes after quenching and tempering are significantly reduced.

Embodiment 2

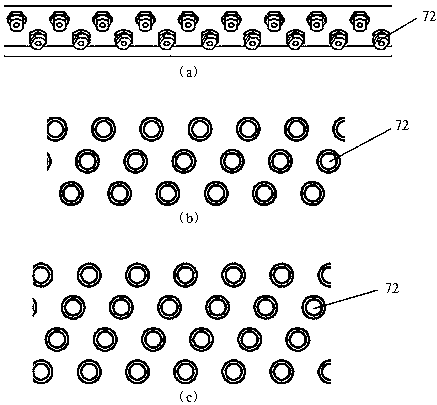

[0098] The C110 steel pipe is tempered and quenched by external spraying and internal spraying. The outer diameter is 88.9mm, the wall thickness of the pipe body is 6.45mm, the wall thickness of the thickened end is 15mm, and the length is 900mm. The parameters are set as follows:

[0099] Speed: 90rpm,

[0100] Internal spray flow: 418m 3 / h ,

[0101] External spray pressure: 0.2MPa,

[0102] Total flow of external spraying: 1500m 3 / h ,

[0103] The water supply device at the thickened end opens in two sections, with a length of 1000mm.

[0104] Water supply pressure at the thickening end: 0.3MPa,

[0105] The total flow of water at the thickening end: 50m 3 / h.

[0106] From Figure 8 It can be seen from the full-length yield strength fluctuation curve (C110 88.9*6.45 full-length yield strength fluctuation curve) that the thickened end water replenishment cooling device and method of the present invention can reduce the yield strength of the thickened end of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com