Polyolefin composition, polyolefin masterbatch, polyolefin film and surface decorative composite material and preparation method of surface decorative composite material

A polyolefin film and composite material technology, applied in the field of decorative materials, can solve the problems of high cost and increase the cost of raw materials, and achieve the effect of dense surface structure and inhibition of surface migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In the fifth aspect, the present invention also provides a method for preparing a surface decoration composite material, the preparation method comprising the following steps: S1, sequentially extruding, molding, and cooling the polyolefin masterbatch according to the present invention to obtain a polyolefin Film; S2. Heating one side surface of the polyolefin film to melt it to form a melting surface to be embossed, and then bonding the foam layer to the other side surface of the polyolefin film and performing lamination-pressing The flowers are processed to obtain composite materials.

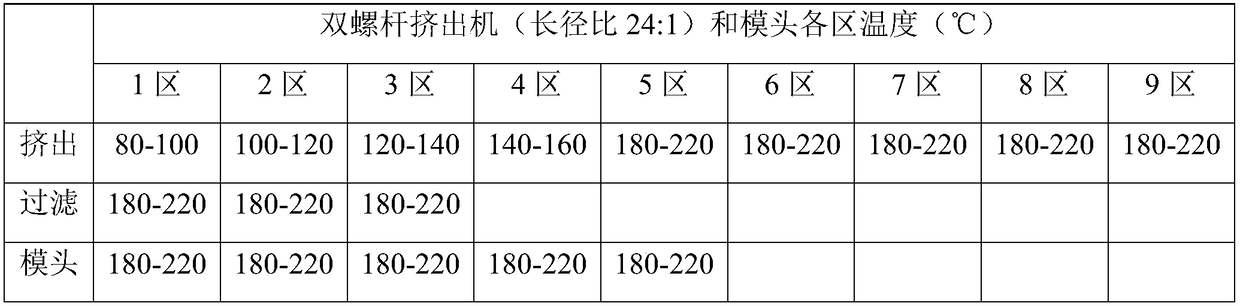

[0039] According to the preparation method of the present invention, the steps of extruding and forming the polyolefin film masterbatch can be carried out in a three-roll calender. For specific operating conditions, reference can be made to conventional operating conditions in the art. Taking the steps of extruding and molding with a three-roll calender as an example, the operating pa...

Embodiment 1-6

[0049] Examples 1-6 and Comparative Documents 1-3

[0050] (1) The polyolefin film composition comprises:

[0051] Thermoplastic polyolefin (TPO): commercially available from Exxon Mobil's TPO CNN010, the melt flow index is 8g / 10min; the density is 0.90g / mL;

[0052] Linear low-density polyethylene (LLDPE): commercially available from Dow DuPont's linear low-density polyethylene 1648, the melt flow index is 3.5g / 10min; density is 0.92g / mL;

[0053] Random copolymer polypropylene (PP-R): commercially available from Yanshan Petrochemical Co., Ltd. random copolymer polypropylene C5908, melt flow index is 9g / 10min; density is 0.91g / mL;

[0054] Cross-linking agent: commercially available dicumyl peroxide from Sinopharm Group;

[0055] Crosslinking auxiliary agent 1: TAIC-70D commercially purchased from Shanghai Changyu Chemical Co., Ltd., wherein the content of triallyl isocyanurate is greater than 70% by weight;

[0056] Cross-linking aid 2: RICON 154DA commercially available ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com