Decorative film as well as cover panel assembly and production process thereof

A production process and decorative film technology, which is applied in the field of touch panels, can solve the problems of edge wrinkles of the decorative film, easy generation of air bubbles on the cover plate and the decorative film, etc., and achieve the effects of good ductility, reduced air bubbles, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

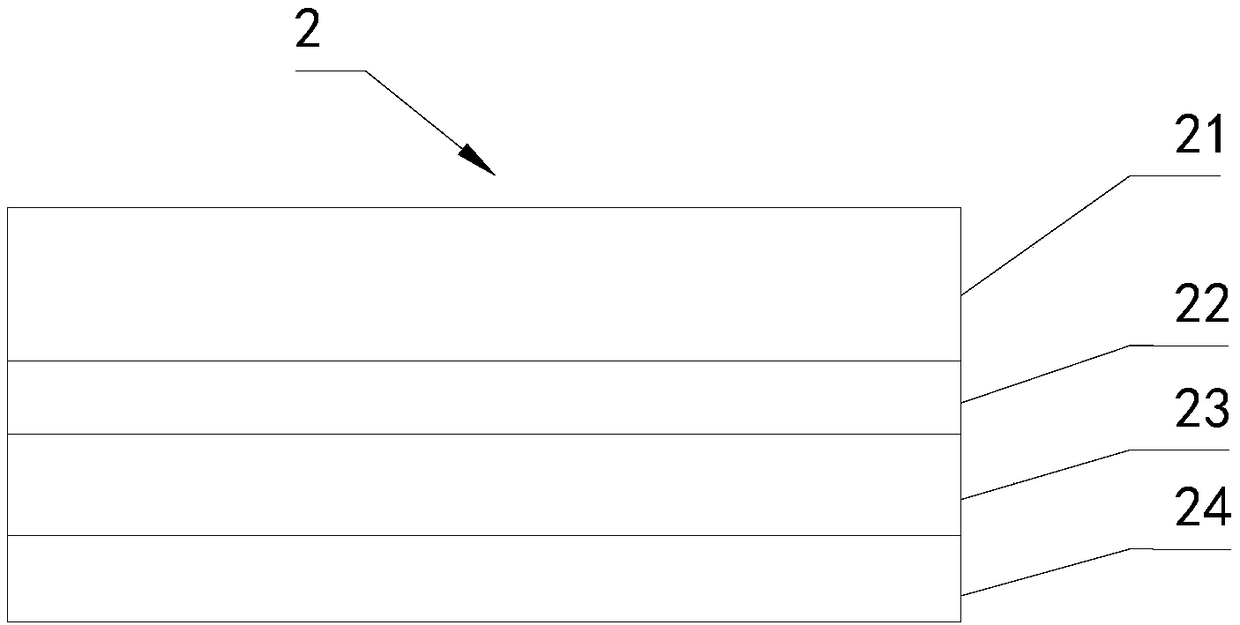

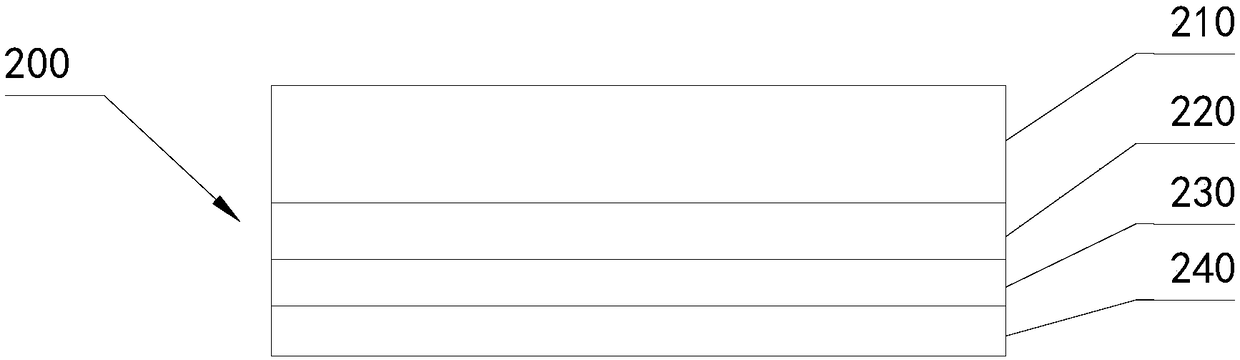

[0053] see image 3 , Figure 4 As shown, the present embodiment provides a decorative film; image 3 The structural schematic diagram of the decorative film provided in this embodiment is shown as a cross-sectional schematic diagram in the figure; Figure 4 Schematic diagram of the structure of the cover plate and the decorative film provided in this embodiment.

[0054] see image 3 , Figure 4As shown, the decorative film provided in this embodiment is suitable for screens of electronic equipment (usually called front covers), especially for non-flat glass screen equipment such as 2.5D and 3D; it is also suitable for battery protection glass of electronic equipment (usually called the back cover). Wherein, the electronic device may be, for example, a mobile phone, a tablet computer, an MP5, and the like.

[0055] The decoration film 200 includes a first film layer 210 , an adhesive layer 220 , a coating layer 230 and a pattern layer 240 .

[0056] The first film laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com