Sorghum stalk sorting machine for liquor brewing

A technology of stem sorting machine and sorghum, which is applied in the field of wine making, can solve the problems of low degree of mechanization, achieve the effect of reducing production cost, reducing misselection rate, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

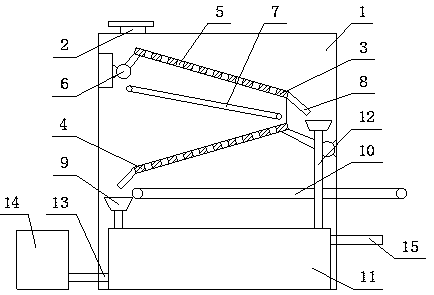

[0010] Embodiment 1: as figure 1 As shown, the present invention comprises a stemming box 1, the top side of the stemming box 1 is provided with a feed port 2, and the upper part of the stemming box 1 is provided with a first sorting bed 3 and a second sorting bed 4 , the first sorting bed 3 and the second sorting bed 4 are all inclined, the first sorting bed 3 is located above the second sorting bed 4, and the high end of the first sorting bed 3 is located below the feed port 2, The high end of the second sorting bed 4 is located below the first sorting bed 3, and several uniformly distributed filter holes 5 are respectively opened on the first sorting bed 3 and the second sorting bed 4, and the first sorting bed The diameter of the filter hole 5 on the 3 is greater than the aperture of the filter hole 5 on the second sorting bed 4, and one end of the first sorting bed 3 and the second sorting bed 4 is respectively provided for driving the first sorting bed 3 and the The dri...

Embodiment 2

[0011] Embodiment 2: Same as the above embodiment 1, wherein the above-mentioned stem sorting box 1 is also provided with a static electricity generating device.

[0012] Pour the material into the stem sorting box 1 from the feed port 2, and drop it onto the first sorting bed 3 for the first sorting. The tea leaves fall from the filter hole to the transition conveyor belt 7, and the tea stems pass through the sliding material. The plate 8 falls into the tea stalk bucket 9, and the materials on the transition conveyor belt 7 fall into the second sorting bed 4 for secondary sorting, and the tea leaves after the secondary sorting fall onto the tea conveyor belt and are sent out for sorting. Stem box 1, the tea stem in the tea stem bucket 9 is sent into the winnowing room by conveying pipe and carries out final sorting.

[0013] The invention has a simple structure and a reasonable design, greatly improves the efficiency and quality of stem picking, greatly reduces the misselecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com