Efficient production method of Pleurotus ostreatus edible fungi

A production method and technology for edible fungi, applied in the directions of botanical equipment and methods, application, mushroom cultivation, etc., can solve the problems of prolonged fruiting period, infection of miscellaneous bacteria, taste, etc., and achieve the effect of saving cost and solving the infection of miscellaneous bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

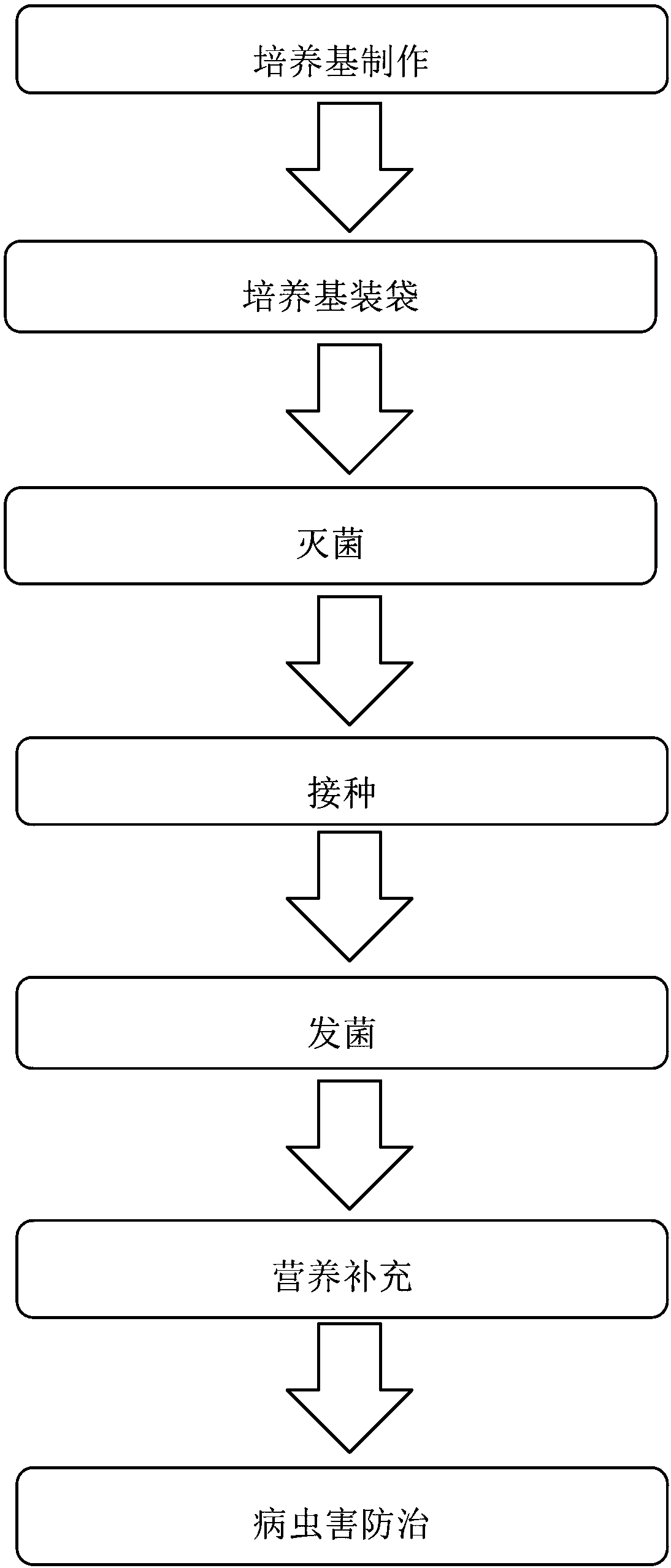

Image

Examples

Embodiment 1

[0033] A high-efficiency production method of oyster mushroom class edible fungus, comprising the following steps:

[0034] (1) Medium production: medium raw materials include the following parts by weight: 70 parts of corn cobs, 10 parts of bagasse, 10 parts of wheat grains, 5 parts of rapeseed cakes, add water and stir until the water content is 65%.

[0035] The preparation steps of the culture medium are:

[0036] i Take 70 parts of corn cobs and 10 parts of bagasse as the culture medium raw material according to the said number, add water and stir evenly, let stand for 48 hours, add water and stir again, make the water content of the mixed culture material reach 65%, let stand for 24 hours;

[0037] ⅱ Take 10 parts of wheat grains and 5 parts of rapeseed cake according to the number of parts, add water to soak for 24 hours, and set aside;

[0038] Ⅲ Stir the mixture described in step ii into the mixed culture material described in step i, stir evenly, and adjust the pH v...

Embodiment 2

[0047] A high-efficiency production method of oyster mushroom class edible fungus, comprising the following steps:

[0048] (1) Medium production: medium raw materials include the following parts by weight: 60 parts of corn cobs, 5 parts of bagasse, 5 parts of wheat grains, 2 parts of rapeseed cake, add water and stir until the water content is 65%.

[0049] The preparation steps of the culture medium are:

[0050]i Take 60 parts of corn cobs and 5 parts of bagasse as the culture medium raw materials according to the number of parts, add water and stir evenly, let stand for 48 hours, add water and stir again, make the water content of the mixed culture material reach 65%, let stand for 24 hours;

[0051] ⅱ Take 5 parts of wheat grains and 2 parts of rapeseed cake according to the number of parts, add water to soak for 24 hours, and set aside;

[0052] Ⅲ Stir the mixture described in step ii into the mixed culture material described in step i, stir evenly, and adjust the pH va...

Embodiment 3

[0061] A high-efficiency production method of oyster mushroom class edible fungus, comprising the following steps:

[0062] (1) Medium production: medium raw material comprises following parts by weight: 80 parts of corncobs, 15 parts of bagasse, 15 parts of wheat grains, 8 parts of rapeseed cakes, add water and stir to water content 65%.

[0063] The preparation steps of the culture medium are:

[0064] ⅰ Take 80 parts of corn cobs and 15 parts of bagasse as the culture medium raw materials according to the number of parts, add water and stir evenly, let stand for 48 hours, add water and stir again, make the water content of the mixed culture material reach 65%, let stand for 24 hours;

[0065] ⅱ Take 15 parts of wheat grains and 8 parts of rapeseed cake according to the number of parts, add water to soak for 24 hours, and set aside;

[0066] Ⅲ Stir the mixture described in step ii into the mixed culture material described in step i, stir evenly, and adjust the pH value to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com