A rapid manufacturing equipment for electronic products

An electronic product, fast technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of easy toppling, corrosion damage of components, slow cooling rate, etc., to achieve scientific and reasonable structure, avoid corrosion damage, safe and convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

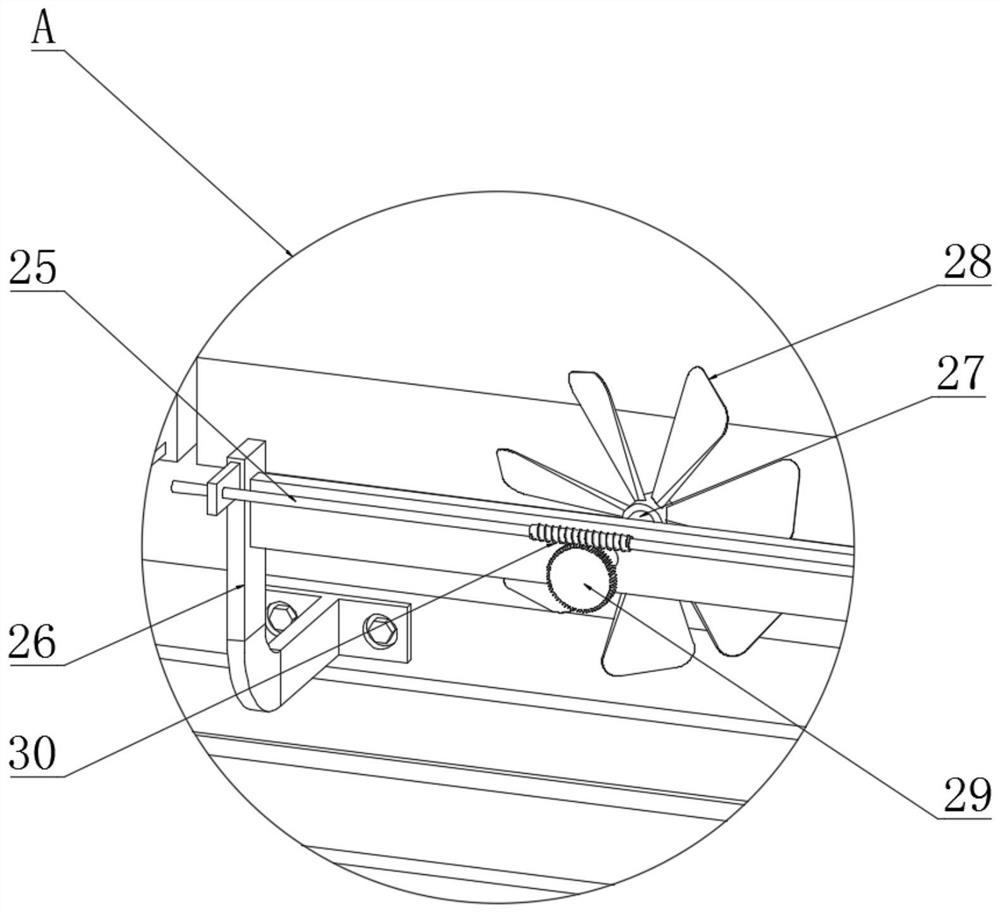

[0029] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a rapid manufacturing equipment for electronic products, including a reflow soldering box 1, a cabinet door 2 is hinged on one side of the reflow soldering box 1, and the surface of the cabinet door 2 is covered with an insect-catching sticky board 3 , the surface of the cabinet door 2 corresponds to the bottom of the insect trapping board 3, and a waste residue storage board 4 is installed. In order to prevent mosquito residues and dust from sliding down from the edge of the waste residue storage board 4, causing the ground to be dirty and difficult to clean, the waste residue storage board 4 A baffle is installed on the edge, a fixed plate 5 is symmetrically installed on the surface of the cabinet door 2 corresponding to the upper position of the sticky plate 3, and a scraper 7 is installed below the fixed plate 5 through an elastic rope 6. Vibration spring 8, damping pad 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com