A kind of precharging method of cylindrical lithium battery

A lithium-ion battery, pre-charging technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, climate sustainability, etc., can solve the problems of self-discharge and water content of lithium-ion batteries, reduce the self-discharge rate, improve the battery cell performance, improve the effect of blackening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

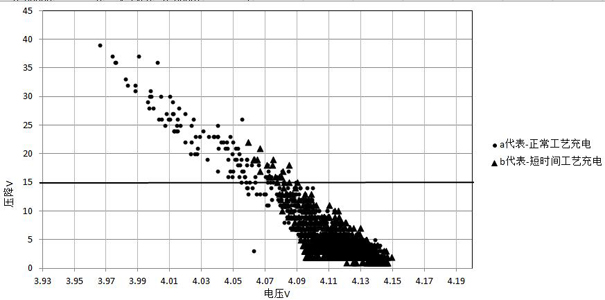

Image

Examples

Embodiment 1

[0018] A kind of cylindrical lithium battery precharging method is carried out according to the following steps:

[0019] 1) Take liquid injection-laser welding-sealing-complete the above-mentioned steps and cover the cylindrical battery cell, and the film-coated battery cell is aged at 23°C and relative humidity 25% and stored for 12 hours, then transferred to next process.

[0020] 2) Transfer the encapsulated battery cells that have completed the above process to the charging cabinet, and the charging and sending process on the cabinet will first sleep for 5 minutes and then charge with a constant current of 1C for 30s. After resting for 5 minutes, turn to the next procedure.

[0021] 3) After the above-mentioned charging is completed, put the cell into the cabinet and carry out aging at room temperature 23°C and relative humidity 25% for 40 hours, and then transfer to the next process.

[0022] 4) Put the batteries that have been aged on the cabinet again to charge and s...

Embodiment 2

[0030] A kind of cylindrical lithium battery precharging method is carried out according to the following steps:

[0031] 1) Take liquid injection-laser welding-sealing-complete the above-mentioned processes and cover the cylindrical cells, and the coated cells are aged at 27°C and relative humidity of 20% and stored for 15 hours, then transferred to next process.

[0032] 2) Transfer the encapsulated battery cells that have completed the above process to the charging cabinet, and the charging and sending process on the cabinet will first sleep for 3 minutes and then charge with a constant current of 1C for 50s. After resting for 4 minutes, turn to the next procedure.

[0033] 3) After the above-mentioned charging is completed, put the cell into the cabinet and carry out aging at room temperature 27°C and relative humidity 25% for 30 hours, and then transfer to the next process.

[0034] 4) Put the batteries that have been aged on the cabinet again to charge and send the pro...

Embodiment 3

[0041] A kind of cylindrical lithium battery precharging method is carried out according to the following steps:

[0042] 1) Take liquid injection-laser welding-sealing-complete the above-mentioned processes and cover the cylindrical cells, and the coated cells are aged at 27°C and relative humidity of 20% and stored for 15 hours, then transferred to next process.

[0043] 2) Transfer the encapsulated battery cells that have completed the above process to the charging cabinet, and the charging and sending process on the cabinet will first sleep for 5 minutes and then charge with a constant current of 1C for 36s. After resting for 5 minutes, turn to the next procedure.

[0044] 3) After the above-mentioned charging is completed, put the cell into the cabinet and carry out aging at room temperature 27°C and relative humidity 25% for 30 hours, and then transfer to the next process.

[0045]4) Put the batteries that have been aged on the cabinet again to charge and send the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com