Secondary drying device of sawdust

A secondary drying and secondary drying technology, which is applied in the direction of drying, drying machine, wood particle drying, etc., can solve the problems of long time spent in natural drying, small amount of sawdust, and large influence of natural conditions, etc., to meet the requirements of Large-scale production requirements, a large amount of drying at one time, and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

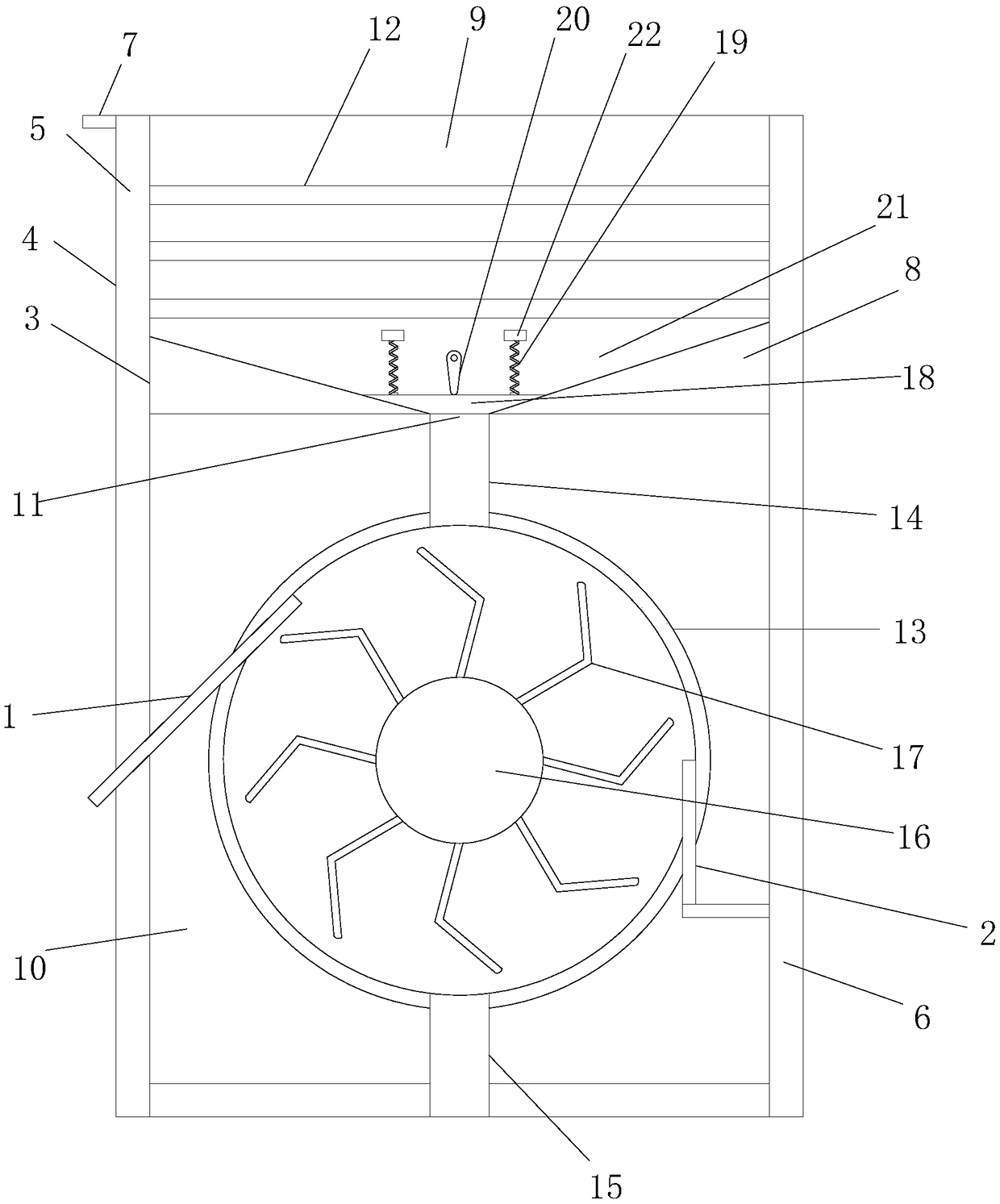

[0012] refer to figure 1 , the present invention proposes a sawdust secondary drying device, comprising a drying box, a hot air inlet pipe 1, a hot air outlet pipe 2, a hot air generator and a controller; wherein:

[0013] The drying box includes an inner casing 3 and an outer casing 4 arranged outside the inner casing 3. An independently closed first air chamber 5 and a second air chamber 6 are formed between the inner casing 3 and the outer casing 4. On the outer casing 4 An exhaust pipe 7 communicating with the first air chamber 5 is provided. The drying box is provided with a partition 8 arranged horizontally. The partition 8 divides the interior of the drying box into a primary drying chamber 9 and a secondary drying chamber 10 arranged up and down. The top surface of the partition 8 is provided with an inverted conical concave. Groove 21, the central position of the inverted tapered groove 21 is provided with a quantitative discharge port 11 communicating with the prima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com