Rapid dragging device for submarine pipeline construction

A technology for submarine pipelines and hauling devices, which is used in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. The blue docking work is convenient and fast, reducing the difficulty of installation and operation, and shortening the operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

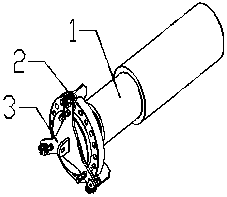

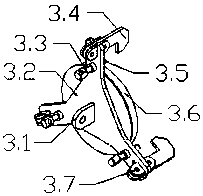

[0016] Attached below figure 1 And attached figure 2 , the present invention is described in detail.

[0017] A flange drag quick connection device 3 for submarine pipeline construction, including a device body 3.2, a drag edge plate 3.1, a jacking screw 3.3, a swing claw 3.4 and a detachable pin shaft 3.7. The device body 3.2 is a group of all components For the installation base, it is a triangular structure cut and processed by a steel plate. The end of the triangle is a notch structure. The upper and lower sides of the notch are welded with lug seats. ; The drag force along the plate 3.1 is in the form of an open ear plate, which is connected with the shackle on the pulling wire rope to transmit the pulling force, and the lower end is welded as one with the device body 3.2; the jacking screw 3.3 is a piece A screw with a small transverse through hole at the end, which can be tightened or loosened by turning it through an iron rod or other rigid hard rod when in use, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com