Inflation protection device and method for welding of pipe fitting

A protection device and pipe fitting welding technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of difficult to meet welding quality requirements, huge material costs, and large nitrogen consumption, so as to improve welding quality and improve welding quality. Efficiency, the effect of improving efficiency

Active Publication Date: 2013-07-31

GUANGZHOU SHIPYARD INTERNATIONAL LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in this way, the nitrogen consumption is large, especially when the pipe is very long, the nitrogen consumption is very large

Moreover, even if a large amount of nitrogen is filled, there will still be a certain amount of oxygen in the tube, which will still have an impact on welding, and the quality of welding is still not enough.

Especially for piping systems with high requirements on welding quality, such as piping systems of chemical tankers, using the above protection method, even if a large amount of nitrogen is filled, the welding quality is still difficult to meet the requirements; Pickling and passivation of the final pipeline system will cost a lot of manpower and huge material costs

In addition, in the current method of inflating the pipe used for welding stainless steel pipes, it is necessary to seal the two ends of the pipe and the weld seam in advance, and then fill it with nitrogen. It takes a long time to fill the pipe with nitrogen to reduce the oxygen content in the pipe, which is time-consuming. gas

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

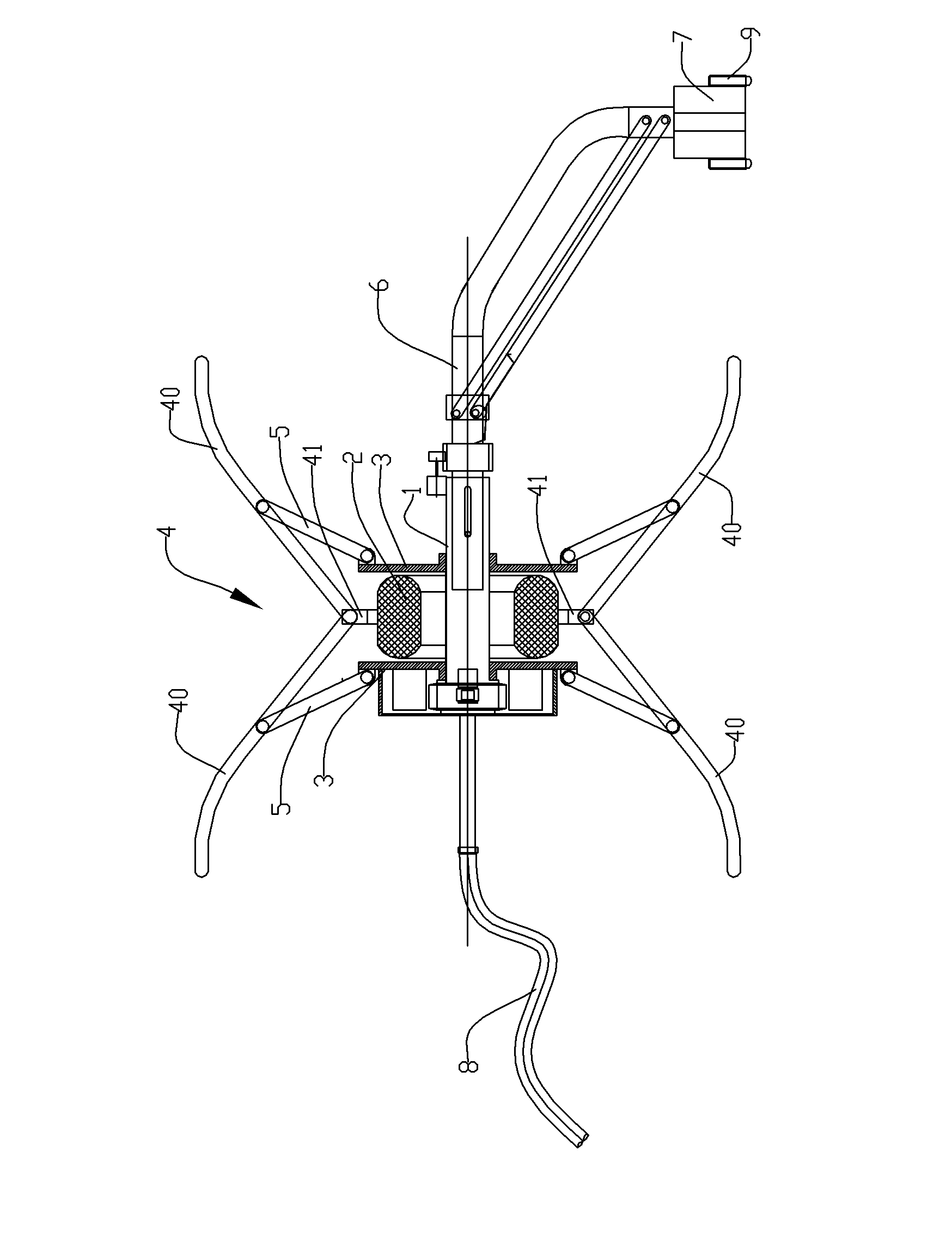

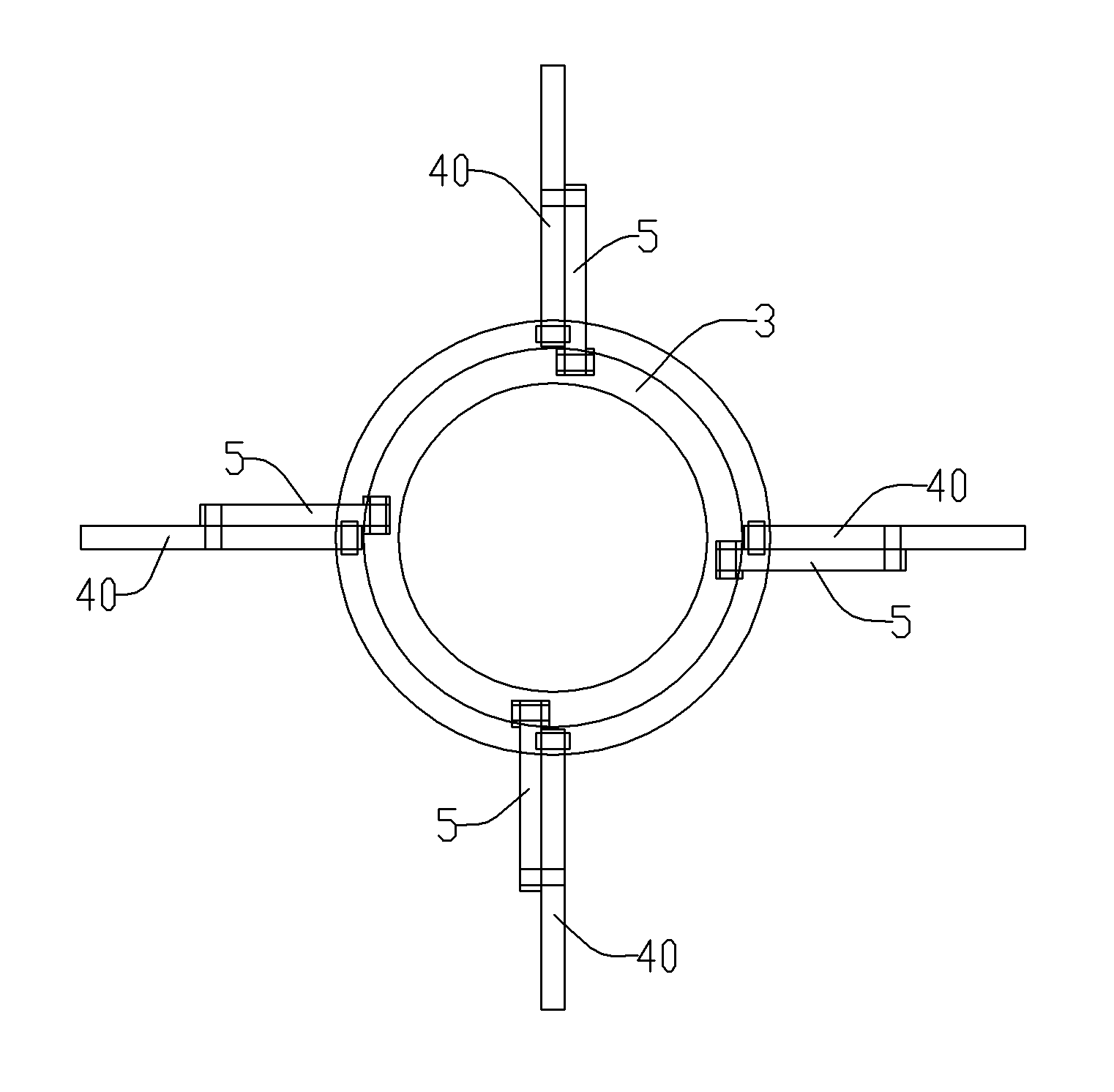

The invention discloses an inflation protection device and method for welding of a pipe fitting, wherein the device is applied in gas protection of the inner wall of a weld joint when butting and welding the pipe fitting and comprises a middle shaft pipe, an expansion gasbag, a sliding plate, a support rod component capable of grasping and loosening the pipe wall, a spray head support extending from one end of the middle shaft pipe and a jet head arranged at the end part of the spray head support. A support rod can grasp and loosen the pipe wall through expansion and contraction of the expansion gasbag, a spray head can rotate directly, when in welding, the jet head can be controlled to aim at the welding part of the weld joint and move along with the welding part. The inflation protection device can pertinently provide gas protection according to the welding part, not only reliably provide anti-oxidation protection for the welding position and can be used for greatly reducing the amount of nitrogen, but also can be simultaneously used for shortening the primary preparation time of welding, and further can be used fro reducing the cost and improving the efficiency under the situation of improving the welding quality.

Description

technical field [0001] The invention relates to an inflatable protection device used on the inner side of the pipe when welding metal pipe fittings. Background technique [0002] When metal pipe fittings are butt welded, due to the extremely high temperature of the welding place, they are easily oxidized by oxygen in the air. When argon arc welding is used, the outer surface of the weld is protected by nitrogen from the torch, and is less oxidized, resulting in better welding quality; but the weld on the inner surface of the pipe fitting and the pipes on both sides of the weld are oxidized, It is easy to form defects such as slag inclusions and cracks, and an unstable oxide layer will form on the surface of the weld, making the pipeline easy to be corroded during use. In order to avoid oxidation on the inner surface of the pipe fittings, during the welding process of the existing metal pipe fittings, the two ends of the butt-welding pipe fittings are usually sealed and f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K9/16B23K9/32

Inventor 何家骥

Owner GUANGZHOU SHIPYARD INTERNATIONAL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com