Marine fuel oil common rail

A technology of fuel oil and common rail, which is applied in the direction of fuel injection devices, engine components, machines/engines, etc. It can solve the problems of common rail processing difficulty and installation difficulty, and achieve the effect of reducing manufacturing difficulty and manufacturing cost and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

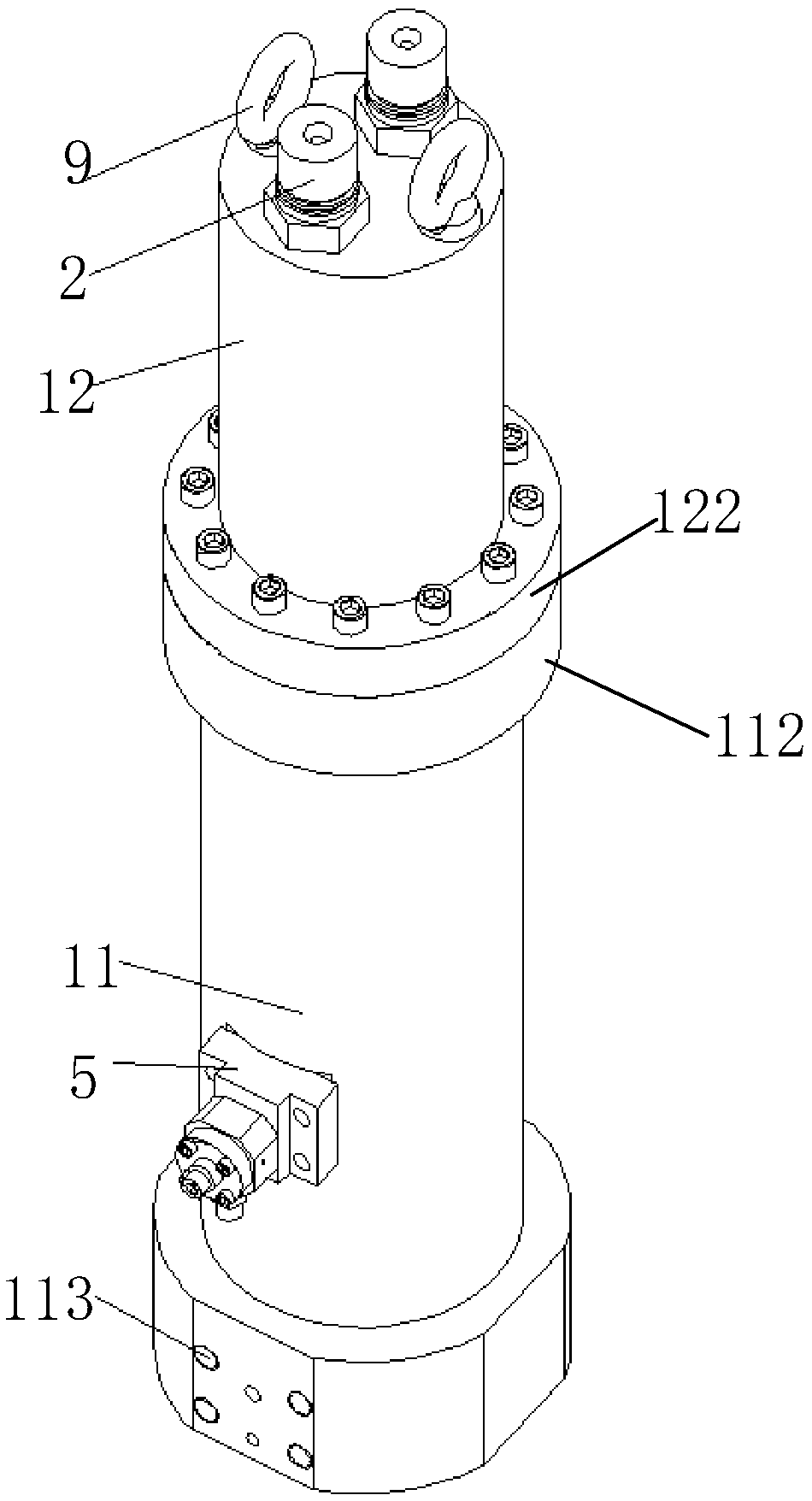

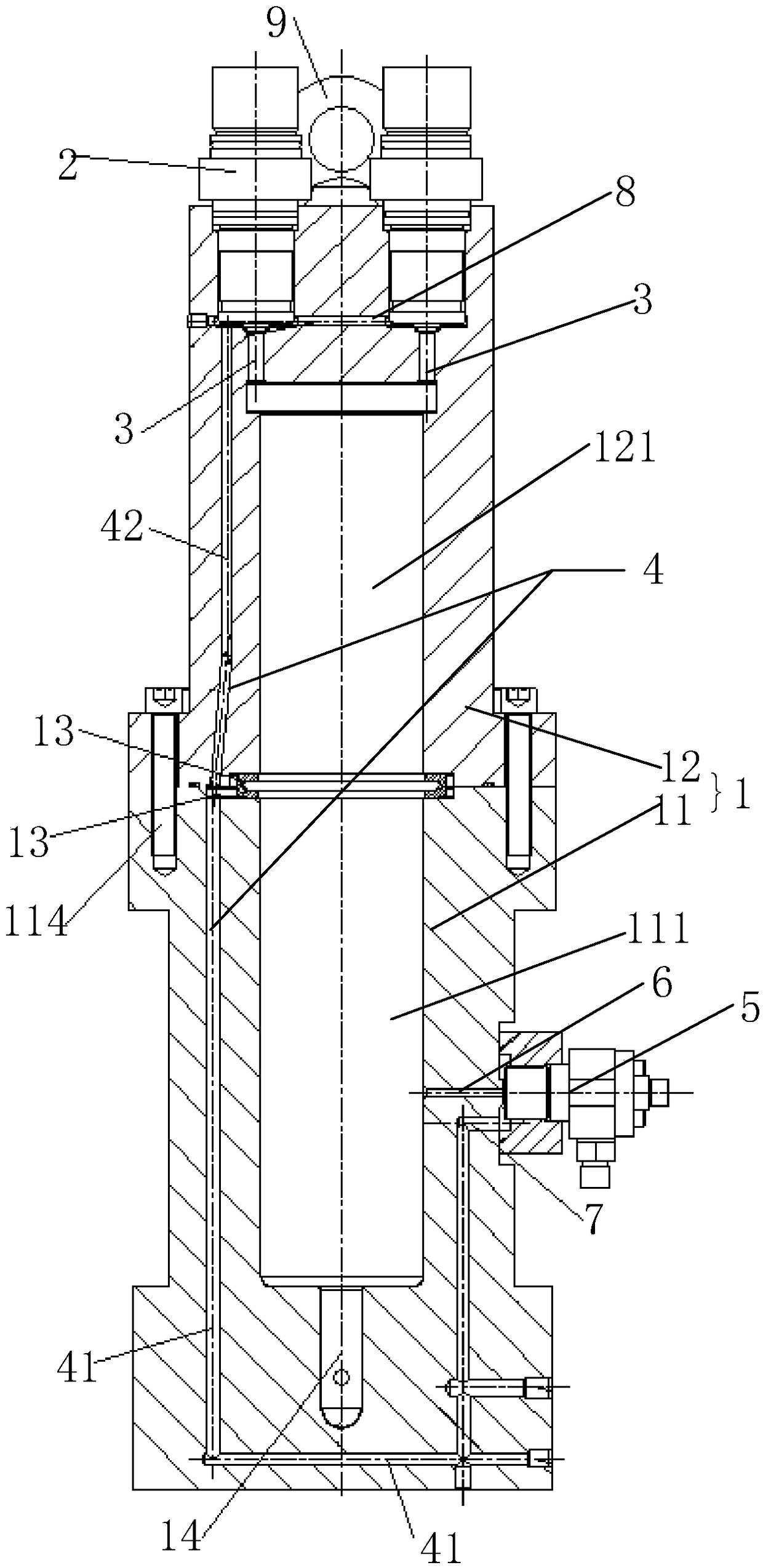

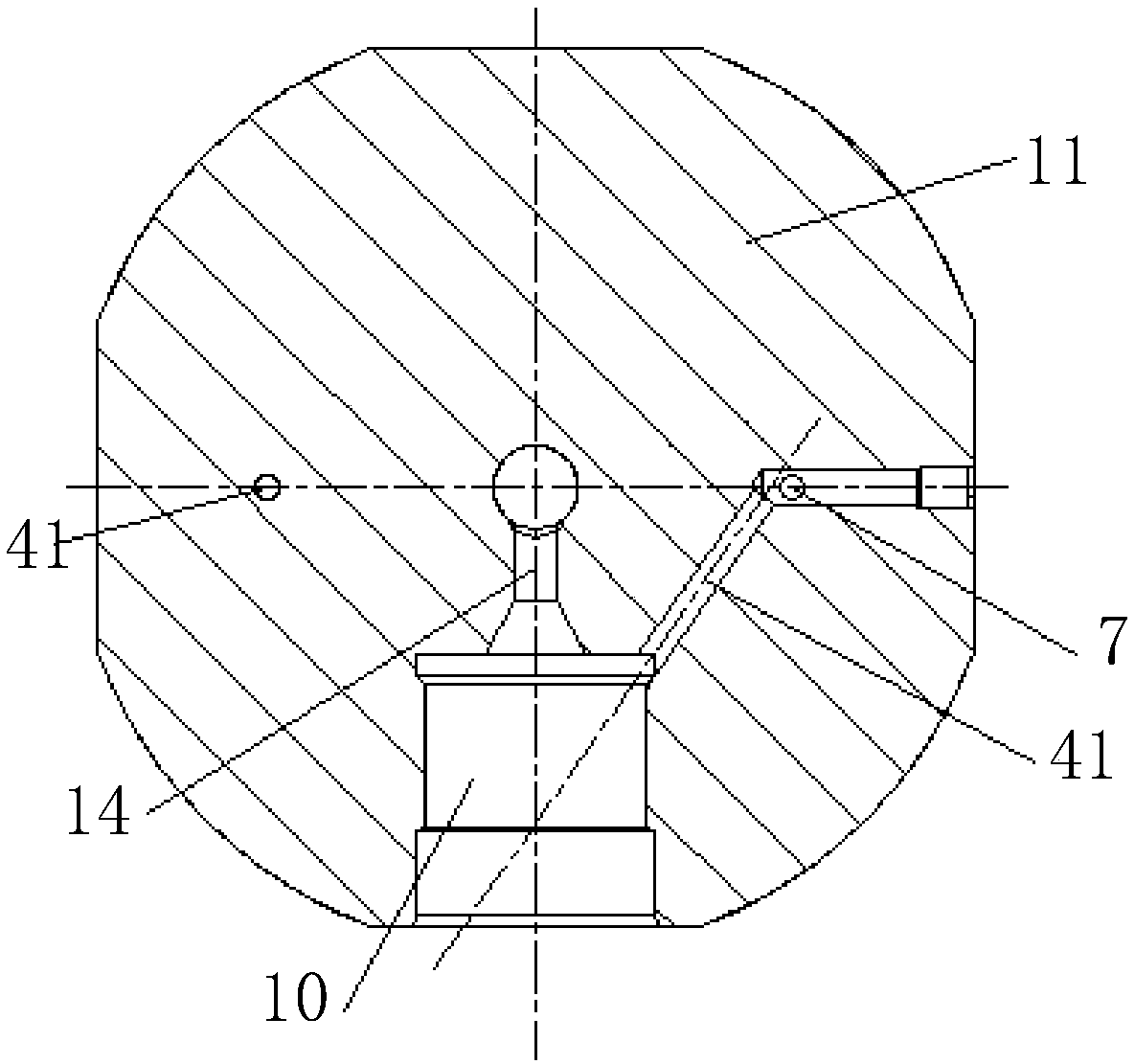

[0033] refer to Figure 1 to Figure 4 , the present invention provides a marine fuel oil common rail, each engine block corresponds to a common rail, the common rail includes: a common rail pipe body 1, which has a fuel chamber communicated with a high-pressure oil inlet pipe 10, the The common rail pipe body 1 is provided with a mounting hole; the restrictor valve 2 used to communicate with the fuel injector is partially inserted in the mounting hole and communicated to the fuel chamber through the first pipeline 3; A first gap 21 for fuel to pass is formed between the restrictor valve 2 and the installation hole; a first fuel return pipeline 4 is formed on the common rail pipe body 1, and the first fuel return pipeline 4. One end is connected to the high-pressure fuel inlet pipe 10, and the other end is connected to the first gap 21; wherein, the fuel in the fuel tank enters the fuel chamber through the high-pressure fuel inlet pipe 10 and passes through the restrictor valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com