Preparation method of nuclear-grade zirconium alloy return scrap cast ingots

A zirconium alloy and return material technology is applied in the field of preparation of nuclear grade zirconium alloy return material ingots, which can solve problems such as low yield and achieve the effect of improving the recovery range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

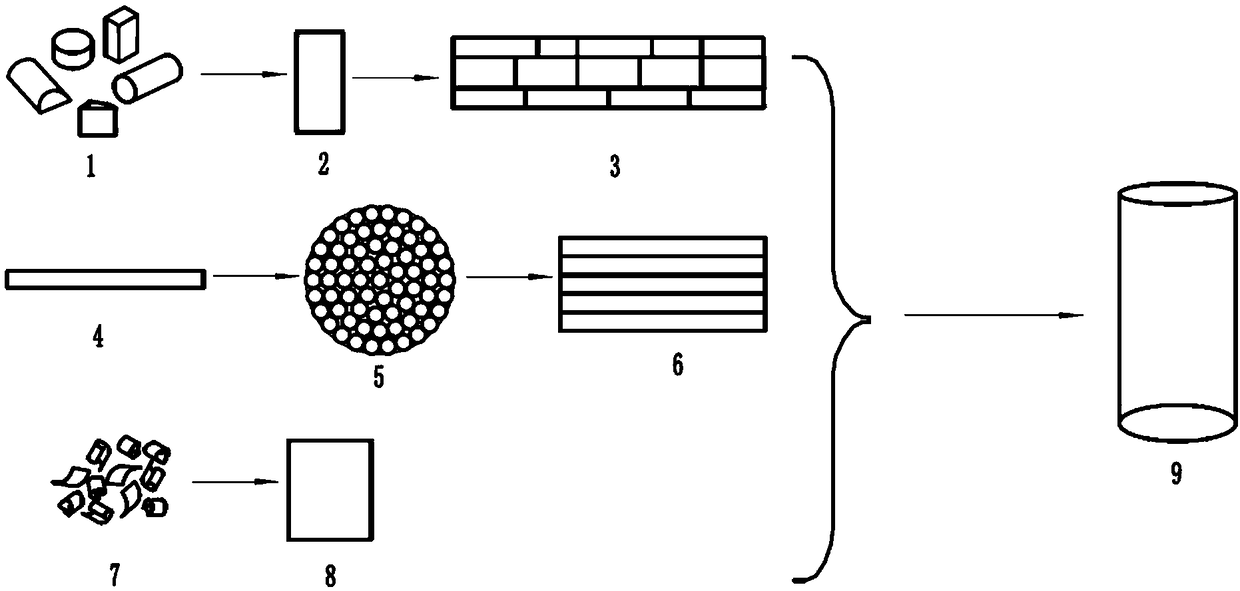

Method used

Image

Examples

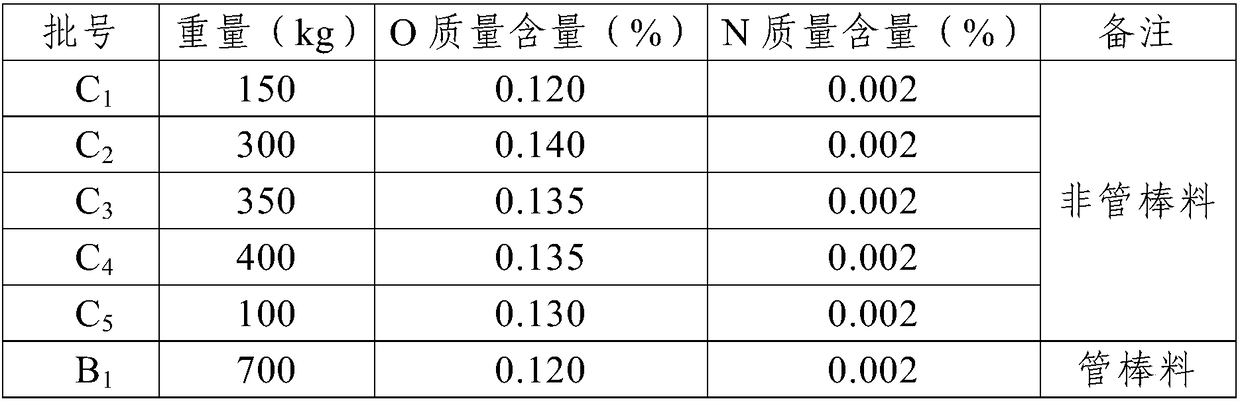

Embodiment 1

[0046] This embodiment includes the following steps:

[0047] Step 1, using a hand-held X-ray fluorescence spectrometer to quickly identify and classify the grades of the zirconium alloy returned materials;

[0048] Step 2. Select zirconium alloy return material with the same grade as Zr-4 alloy or similar chemical composition to carry out pretreatment; the zirconium alloy return material is scrap zirconium alloy return material or block zirconium alloy return material; the scrap zirconium alloy return material Alloy return materials include all kinds of chips generated during the processing of zirconium materials; the block zirconium alloy return materials include tubular rod-shaped zirconium alloy return materials and non-tube rod-shaped zirconium alloy return materials generated in the processing of zirconium materials; The pretreatment of zirconium alloy return material includes the following steps:

[0049] Step 201. Cutting: classify scrap zirconium alloy return materia...

Embodiment 2

[0071] This embodiment includes the following steps:

[0072] Step 1, using a hand-held X-ray fluorescence spectrometer to quickly identify and classify the grades of the zirconium alloy returned materials;

[0073] Step 2. Select zirconium alloy return material with the same grade as Zr-4 alloy or similar chemical composition to carry out pretreatment; the zirconium alloy return material is scrap zirconium alloy return material or block zirconium alloy return material; the scrap zirconium alloy return material Alloy return materials include all kinds of chips generated during the processing of zirconium materials; the block zirconium alloy return materials include tubular rod-shaped zirconium alloy return materials and non-tube rod-shaped zirconium alloy return materials generated in the processing of zirconium materials; The pretreatment of zirconium alloy return material includes the following steps:

[0074] Step 201, shearing: classify the chip-like zirconium alloy retur...

Embodiment 3

[0095] This embodiment includes the following steps:

[0096] Step 1, using a hand-held X-ray fluorescence spectrometer to quickly identify and classify the grades of the zirconium alloy returned materials;

[0097] Step 2. Select zirconium alloy return material with the same grade as Zr-4 alloy or similar chemical composition to carry out pretreatment; the zirconium alloy return material is scrap zirconium alloy return material or block zirconium alloy return material; the scrap zirconium alloy return material Alloy return materials include all kinds of chips generated during the processing of zirconium materials; the block zirconium alloy return materials include tubular rod-shaped zirconium alloy return materials and non-tube rod-shaped zirconium alloy return materials generated in the processing of zirconium materials; The pretreatment of zirconium alloy return material includes the following steps:

[0098] Step 201. Cutting: classify scrap zirconium alloy return materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com