Single-component conductive silica gel for solar packaging and preparation method thereof

A technology of solar energy encapsulation and conductive silica gel, which is applied in the direction of conductive adhesives, circuits, adhesives, etc., can solve the problems of unsatisfactory aging performance, low temperature resistance, inability to meet the needs of fast stacking of assembly lines, and huge cost pressures. Low cost, good aging resistance, low hot spot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

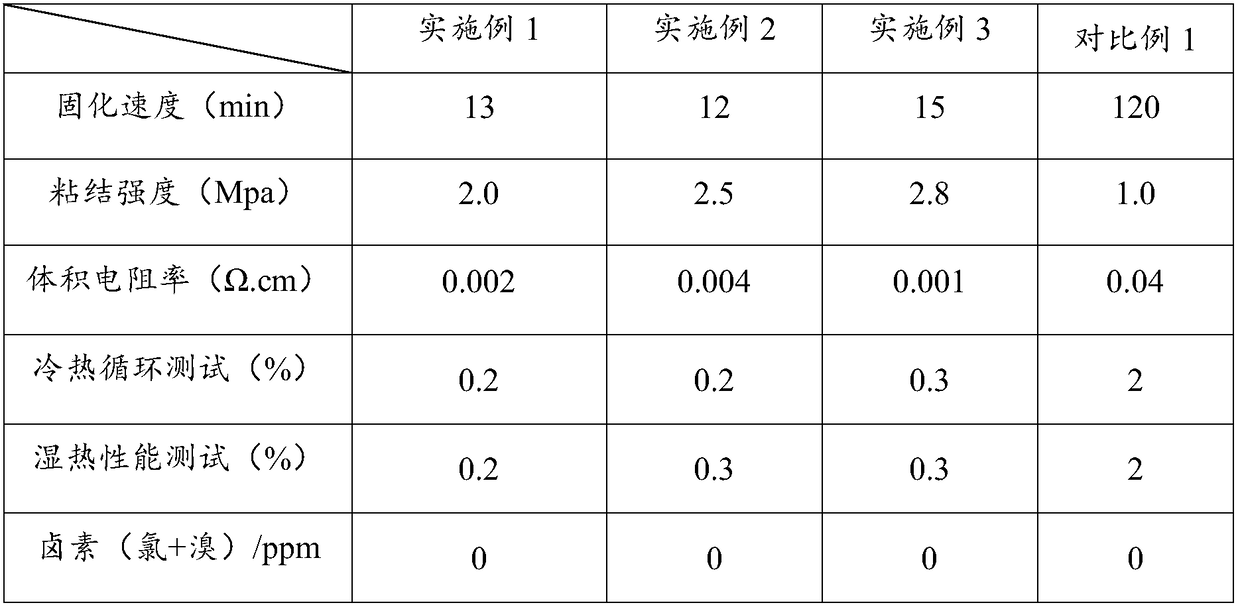

Examples

Embodiment 1

[0031] At room temperature, according to the components specified in Example 1 in Table 1, liquid methyl vinyl silicone oil with a vinyl content of 0.05 mmol / g and a viscosity of 50,000 cps, coupling agents KH560, Z-6040 and gas silicon R974 were placed in Knead in the kneader, knead for 1 hour until uniform, add solvent OS-10, silicon gas R8200 and mix for 20 minutes, then put low hydrogen silicone oil, terminal hydrogen silicone oil, epoxy silicone oil, vinyl silicone oil and platinum catalyst into the Mix in a double planetary mixer for 10-20 minutes until uniform, and finally add self-made modified silver powder AC-0295 and SF-30 three times, and mix at room temperature for 30 minutes in a vacuum at a low speed to obtain the solar energy encapsulation of the present invention. Conductive plastic.

[0032] Modification of silver powder: add 150ml of toluene to a four-neck flask, add 0.8g of coupling agent KH560, 50g of silver powder AC-0295 and SF-30, heat at 110°C and stir...

Embodiment 2

[0034] At room temperature, according to the components specified in Example 2 in Table 1, liquid methyl vinyl silicone oil with a vinyl content of 0.05 mmol / g and a viscosity of 50,000 cps, coupling agents KH560, Z-6040 and gas silicon R974 were placed in Knead in the kneader, knead for 1 hour until uniform, add solvent G-120, gas silicone R8200 and mix for 20 minutes, then put low hydrogen-containing silicone oil, terminal hydrogen-containing silicone oil, epoxy silicone oil, vinyl silicone oil and platinum catalyst into the Mix in a double planetary mixer for 10 to 20 minutes until uniform, and finally add self-made modified silver powder P777-1 and SF-30 three times, and mix at room temperature for 30 minutes in a vacuum at a low speed to obtain the conductive powder for solar energy packaging of the present invention. glue.

[0035] Modification treatment of silver powder: add 150ml xylene to a four-neck flask, add 0.8g coupling agent KH560, 60g each of silver powder P777...

Embodiment 3

[0037] At room temperature, according to the components specified in Example 3 in Table 1, liquid methyl vinyl silicone oil with a vinyl content of 0.05 mmol / g and a viscosity of 50,000 cps, coupling agents KH560, Z-6040 and gas silicon R974 were placed in Knead in the kneader, knead for 1 hour until uniform, add solvent G-120, gas silicone R8200 and mix for 20 minutes, then put low hydrogen silicone oil, terminal hydrogen silicone oil, epoxy silicone oil, vinyl silicone oil and platinum catalyst into the Mix in a double planetary mixer for 10-20 minutes until uniform, and finally add self-made modified silver powder AC-0295, P777-1 and SF-30 in three times, and mix at room temperature for 30 minutes in a vacuum at a low speed to prepare the solar energy Encapsulated conductive adhesive.

[0038]Modification of silver powder: add 150ml of toluene to a four-neck flask, add 0.8g of coupling agent Z-6040, 50g of silver powder AC-0295, P777-1 and SF-30, heat at 110°C and stir at h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com