High-temperature-sintering varnish cured under LED-UV cold light source and preparation method of the varnish

A technology of cold light source curing and high temperature sintering, applied in inks, household appliances, applications, etc., can solve the problems of air pollution, slow drying, poor ink performance, etc., to improve mechanical properties, printing performance, and flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

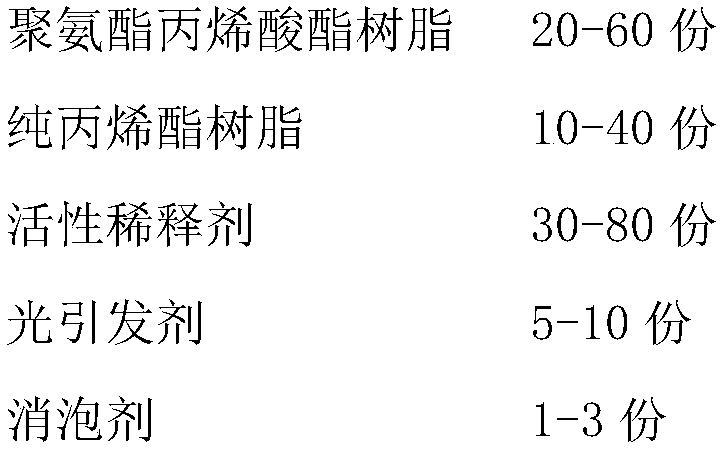

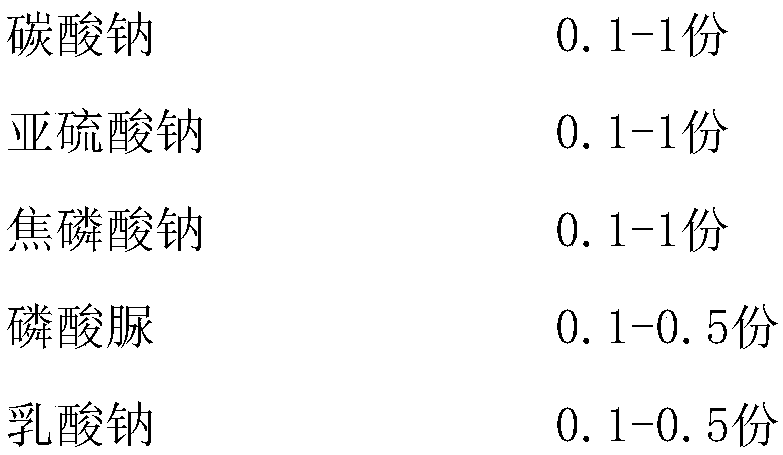

[0046] A high-temperature sintered varnish cured by an LED-UV cold light source, consisting of the following formula:

[0047]

[0048] Its preparation method is:

[0049] S1. Mix polyurethane acrylate resin, pure propylene resin, dehydrated malic anhydride resin, sodium carbonate, and 60% active diluent, heat to 70°C, stir and disperse at a stirring speed of 1200r / min for 30min, and cool to room temperature, spare;

[0050] S2. Mix the terpene resin, sodium sulfite, sodium pyrophosphate, and the remaining active diluent, heat to 60°C, stir and disperse at a stirring speed of 1200r / min for 30min, cool to room temperature, and set aside;

[0051] S3. Mix the intermediates obtained in steps S1 and S2, heat to 35°C, stir and disperse at a stirring speed of 500r / min for 60min, then add surfactant and urea phosphate, heat to 50°C, and stir at a stirring speed of 800r / min Stir and disperse at a stirring speed for 40 minutes, continue to add photoinitiator and sodium lactate, he...

Embodiment 2

[0063] A high-temperature sintered varnish cured by an LED-UV cold light source, consisting of the following formula:

[0064]

[0065] Its preparation method is:

[0066] S1. Mix polyurethane acrylate resin, pure propylene resin, dehydrated malic anhydride resin, sodium carbonate, and 65% active diluent, heat to 75°C, stir and disperse at a stirring speed of 1400r / min for 40min, and cool to room temperature, spare;

[0067] S2. Mix terpene resin, sodium sulfite, sodium pyrophosphate and the remaining active diluent, heat to 65°C, stir and disperse at a stirring speed of 1400r / min for 40min, cool to room temperature, and set aside;

[0068] S3. Mix the intermediates obtained in steps S1 and S2, heat to 40°C, stir and disperse at a stirring speed of 600r / min for 70min, then add surfactant and urea phosphate, heat to 55°C, and stir at a stirring speed of 900r / min Stir and disperse at a stirring speed for 50 minutes, continue to add photoinitiator and sodium lactate, heat to...

Embodiment 3

[0075] A high-temperature sintered varnish cured by an LED-UV cold light source, consisting of the following formula:

[0076]

[0077] Its preparation method is:

[0078] S1. Mix polyurethane acrylate resin, pure propylene resin, dehydrated malic anhydride resin, sodium carbonate, and 70% active diluent, heat to 80°C, stir and disperse at a stirring speed of 1500r / min for 60min, and cool to room temperature, spare;

[0079] S2. Mix terpene resin, sodium sulfite, sodium pyrophosphate and the remaining active diluent, heat to 70°C, stir and disperse at a stirring speed of 1500r / min for 60min, cool to room temperature, and set aside;

[0080] S3. Mix the intermediates obtained in steps S1 and S2, heat to 45°C, stir and disperse at a stirring speed of 700r / min for 80min, then add surfactant and urea phosphate, heat to 60°C, and stir at a stirring speed of 1000r / min Stir and disperse at a stirring speed for 60 minutes, continue to add photoinitiator and sodium lactate, heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com