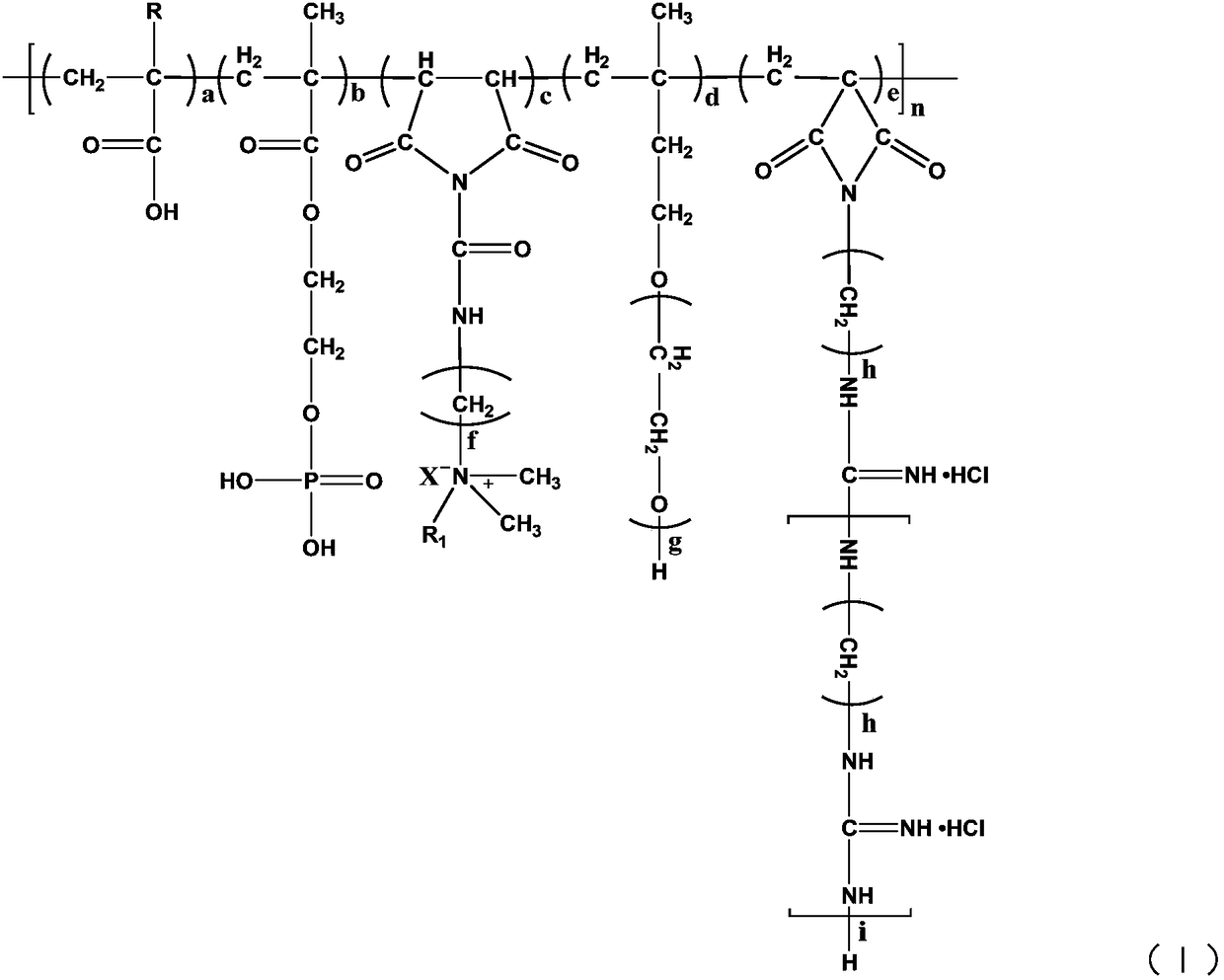

Amphoteric polycarboxylate-type efficient water reducing agent with viscosity reduction and antibiotic properties and preparation method thereof

A high-efficiency water-reducing agent and polycarboxylic acid-based technology, applied in the field of cement admixtures, can solve the problems of limited use, high price, and limited air-entraining viscosity-reducing effect, etc., to reduce concrete viscosity, improve surface activity, and water-reducing performance Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment sets the viscosity-reducing antibacterial amphoteric polycarboxylic acid water reducer, using prenol polyoxyalkylene ether, unsaturated acid, unsaturated phosphoric acid ester, cationic monomer and antibacterial monomer as the main raw materials. It is formed by free radical polymerization under the action of chain transfer agent. The specific steps are as follows:

[0051] Preparation of cationic monomer: Dissolve 1 mol of maleic anhydride and sodium hydroxide in ethanol, stir and heat to 50°C, add 1.05 mol of urea, and after reacting for 2 hours, continue to add 1.05 mol of N,N-di to the reactor Methyl-1,2-ethylenediamine, after reacting for 3 hours, 1.1 mol of 1-chlorobutane was added and part of sodium hydroxide was added, and the temperature was raised to 50° C. and reacted for 3 hours to obtain a cationic monomer.

[0052] Preparation of antibacterial monomer: Put 1mol of guanidine hydrochloride and 1.2mol of ethylenediamine in a reactor, first react at...

Embodiment 2

[0060] This embodiment sets the viscosity-reducing antibacterial amphoteric polycarboxylic acid water reducer, using prenol polyoxyalkylene ether, unsaturated acid, unsaturated phosphoric acid ester, cationic monomer and antibacterial monomer as the main raw materials. It is formed by free radical polymerization under the action of chain transfer agent. The specific steps are as follows:

[0061] Preparation of cationic monomer: Dissolve 1 mol of maleic anhydride and sodium hydroxide in ethanol, stir and heat to 50°C, add 1.05 mol of urea, and after reacting for 2 hours, continue to add 1.06 mol of N,N-di to the reactor Methyl-1,3-propanediamine, after reacting for 3 hours, 1.15 mol of 1-chloropentane was added and a part of sodium hydroxide was added, and the temperature was raised to 50° C. to react for 3 hours to obtain a cationic monomer.

[0062] Preparation of antibacterial monomer: Place 1 mol of guanidine hydrochloride and 1.2 mol of propylene diamine in a reactor, first re...

Embodiment 3

[0070] This embodiment sets the viscosity-reducing antibacterial amphoteric polycarboxylic acid water reducer, using prenol polyoxyalkylene ether, unsaturated acid, unsaturated phosphoric acid ester, cationic monomer and antibacterial monomer as the main raw materials. It is formed by free radical polymerization under the action of chain transfer agent. The specific steps are as follows:

[0071] Preparation of cationic monomer: Dissolve 1 mol of maleic anhydride and sodium hydroxide in ethanol, stir and heat to 50°C, add 1.05 mol of urea, and after reacting for 2 hours, continue to add 1.05 mol of N,N-di to the reactor Methyl-1,4-butanediamine, after 3.5 hours of reaction, 1.15 mol of 1-chlorohexane was added, sodium hydroxide was added, and the temperature was raised to 60° C. to react for 3 hours to obtain a cationic monomer.

[0072] Preparation of antibacterial monomer: Put 1mol of guanidine hydrochloride and 1.2mol of 1,4-butanediamine in the reactor, first react at 100℃ for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com