Preparation method and device for p-cresol

A p-cresol and toluene technology, applied in the field of p-cresol preparation, can solve the problems of shortening, high cost, and equipment investment reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] In order to have a clearer understanding of the technical features, purposes and beneficial effects of the present invention, the technical solution of the present invention is described in detail below, but it should not be construed as limiting the scope of implementation of the present invention.

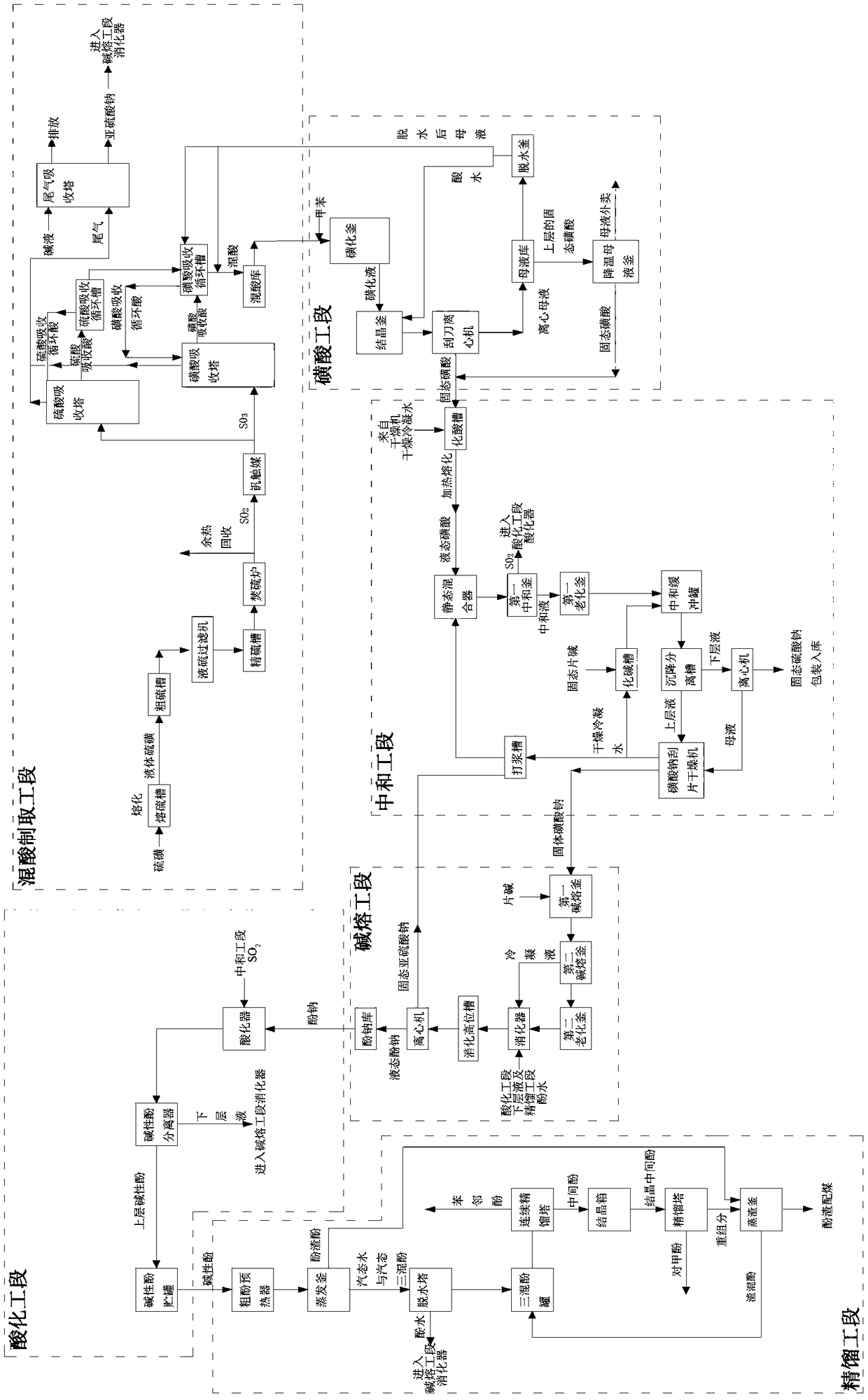

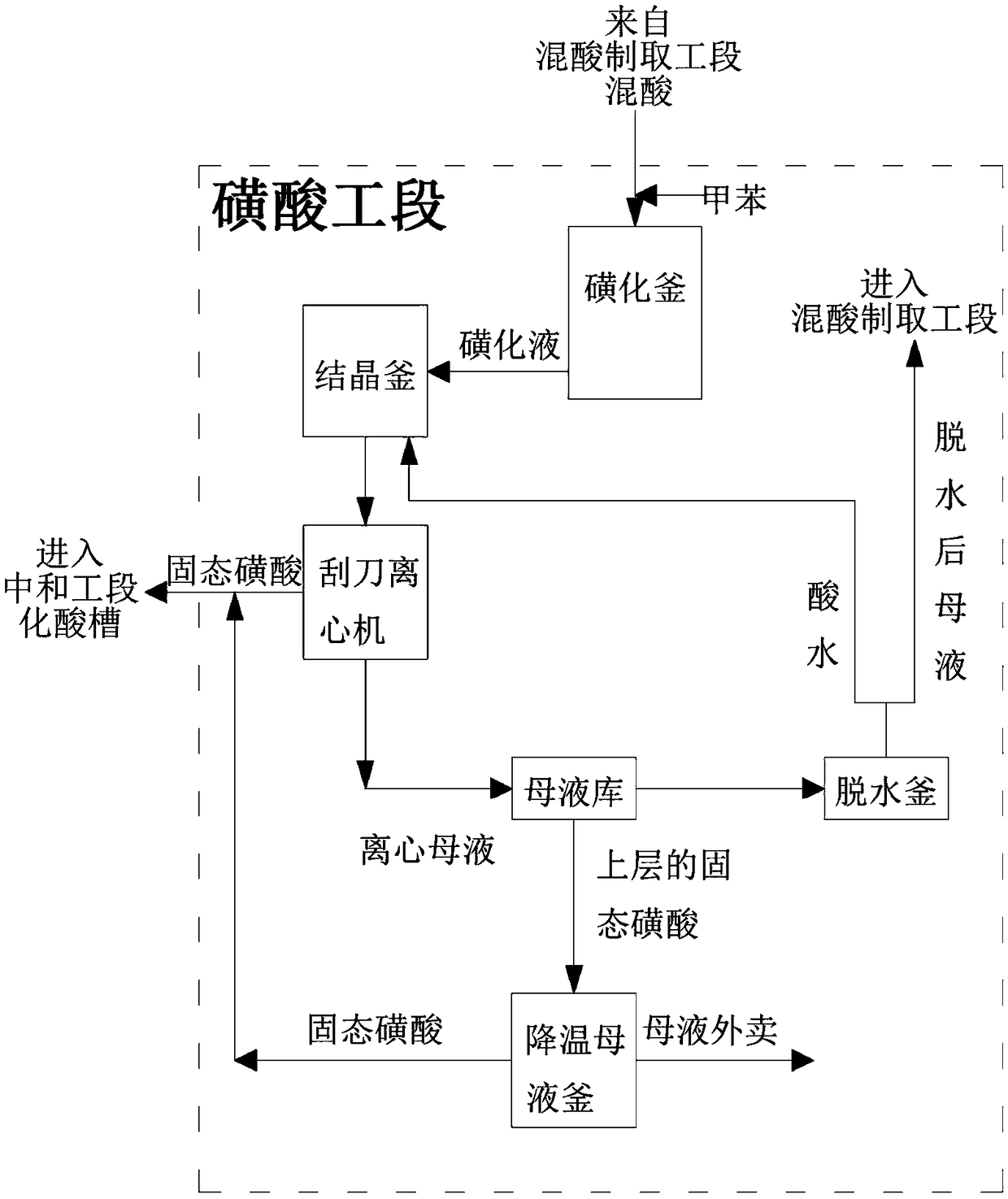

[0083] The inventor has improved on the previous production p-cresol technique, and the continuous production technique of the present invention is divided into six workshops altogether, as figure 1 Shown:

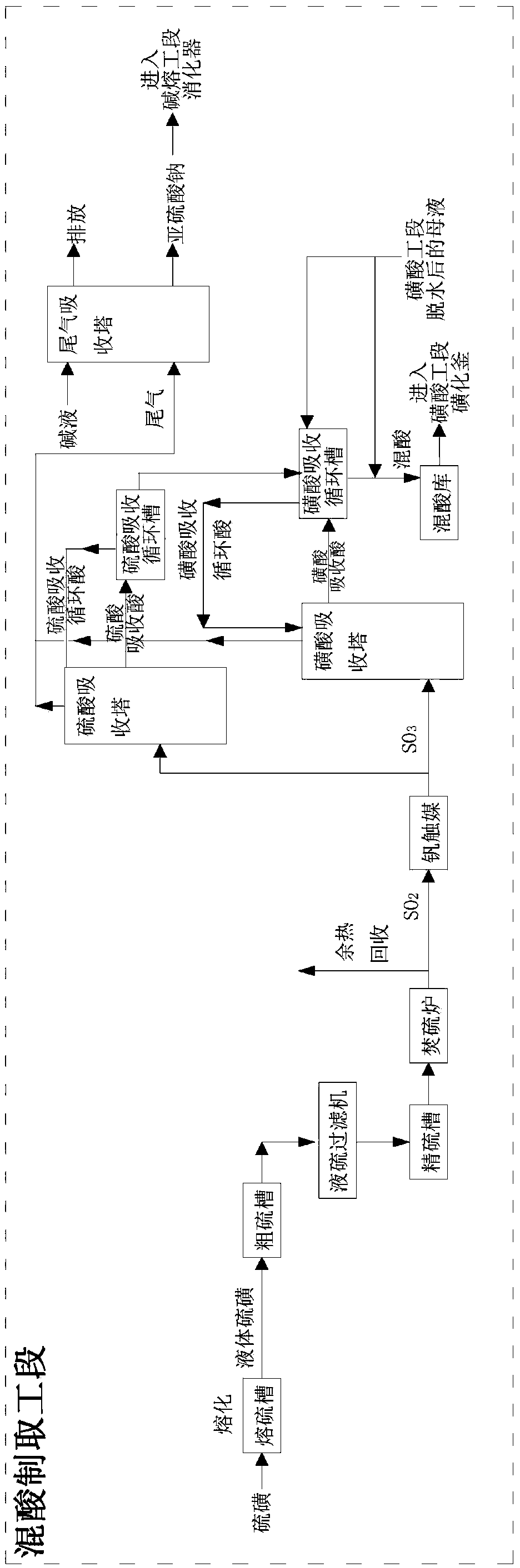

[0084] (1) Mixed acid production section (such as figure 2 shown):

[0085] 1. Sulfur incineration process: The solid sulfur is transported by the belt to the molten sulfur tank for melting, and the liquid sulfur flows from the overflow port to the crude sulfur tank, and is pumped into the liquid sulfur filter and filtered, and then flows into the refined sulfur tank (or by The liquid sulfur in the above-ground refined sulfur tank is automatically controlled to a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com