A kind of green high-early-strength low-alkali liquid accelerator and preparation method thereof

An early-strength, quick-setting agent technology, applied in the field of building materials, can solve problems such as small market share, high price, and uncommon products, and achieve the effects of improving adhesion, high early strength, and high compact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

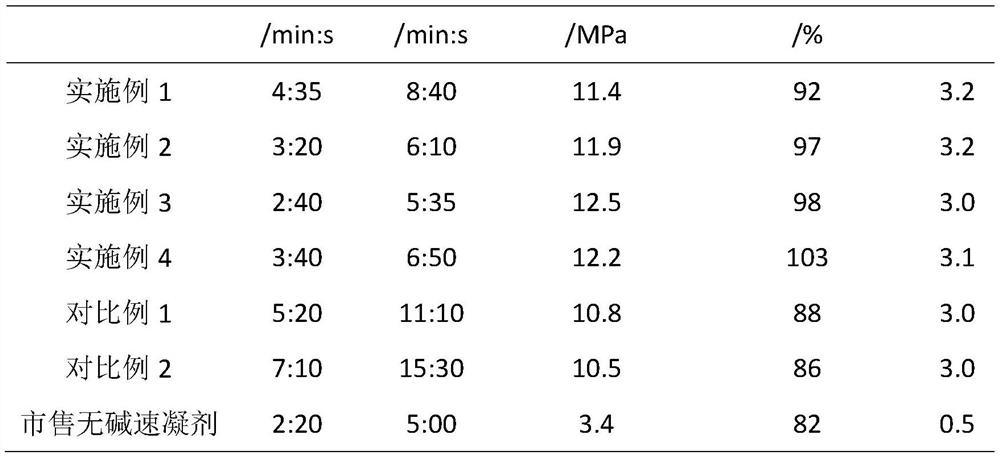

Examples

Embodiment 1

[0030] Aluminum sulfate (38%), sodium fluoride (15%), ethanol (10%), triethanolamine (8%), warm wheel glue (2%), polydimethylsiloxane (0.5 %), The rest is water.

[0031] A method of preparing a low-alkali liquid spurgeon for spray concrete, including the following steps:

[0032] (1) Add water to the water bath container to 60 ° C to 70 ° C;

[0033] (2) Maintain the agitation state, and add fluorinated sodium fluoride and aluminum to the water;

[0034] (3) The stabilizer is slowly added dropwise with the constant current pump, ie the modified alkylamine, and the dropwise time is completed within 1 h-1.5 h;

[0035] (4) Keep the constant temperature, add aluminum sulfate, and stir it to completely dissolve;

[0036] (5) Transfer the above solution to the laboratory high-speed shear emulsifier, the suspending agent and the antifoaming agent are added, and the high-speed shear emulsifier is activated. The speed is adjusted to 3000-5000 r / min, and the emulsification is 0.5h-1 h. ...

Embodiment 2

[0038] Aluminum sulfate (45%), sodium fluoride (10%), isopropanol aluminum (8%), triethanolamine maleate (6%), warm wheel glue (3%), polydimethylsiloxane (1%), the rest is water.

[0039] Preparation method Reference Example 1.

Embodiment 3

[0041] Aluminum sulfate (50%), sodium fluoride (10%), aluminum (6%), triethoxide (4%), xanthan gum (2%), polydimethylsiloxane (0.5%) ), The rest is water.

[0042] Preparation method Reference Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com