Blow molding processing method of CPP film

A processing method and film tube technology, which is applied in the field of CPP film blow molding, can solve the problems of easy breakage of the film tube and unstable traction of the film tube, so as to increase the utilization rate, alleviate the unstable traction, and reduce the force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following is further described in detail through specific implementation methods:

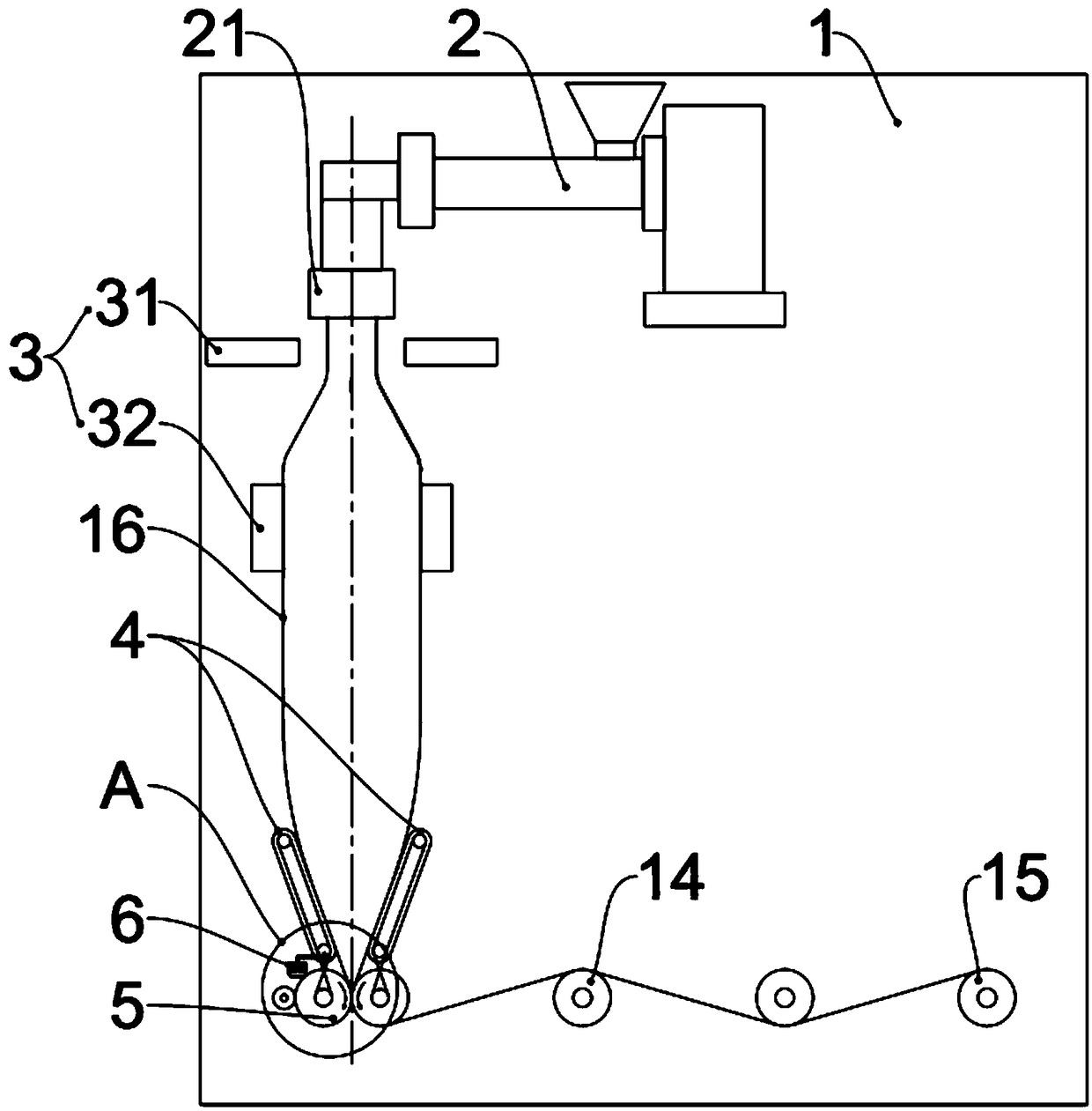

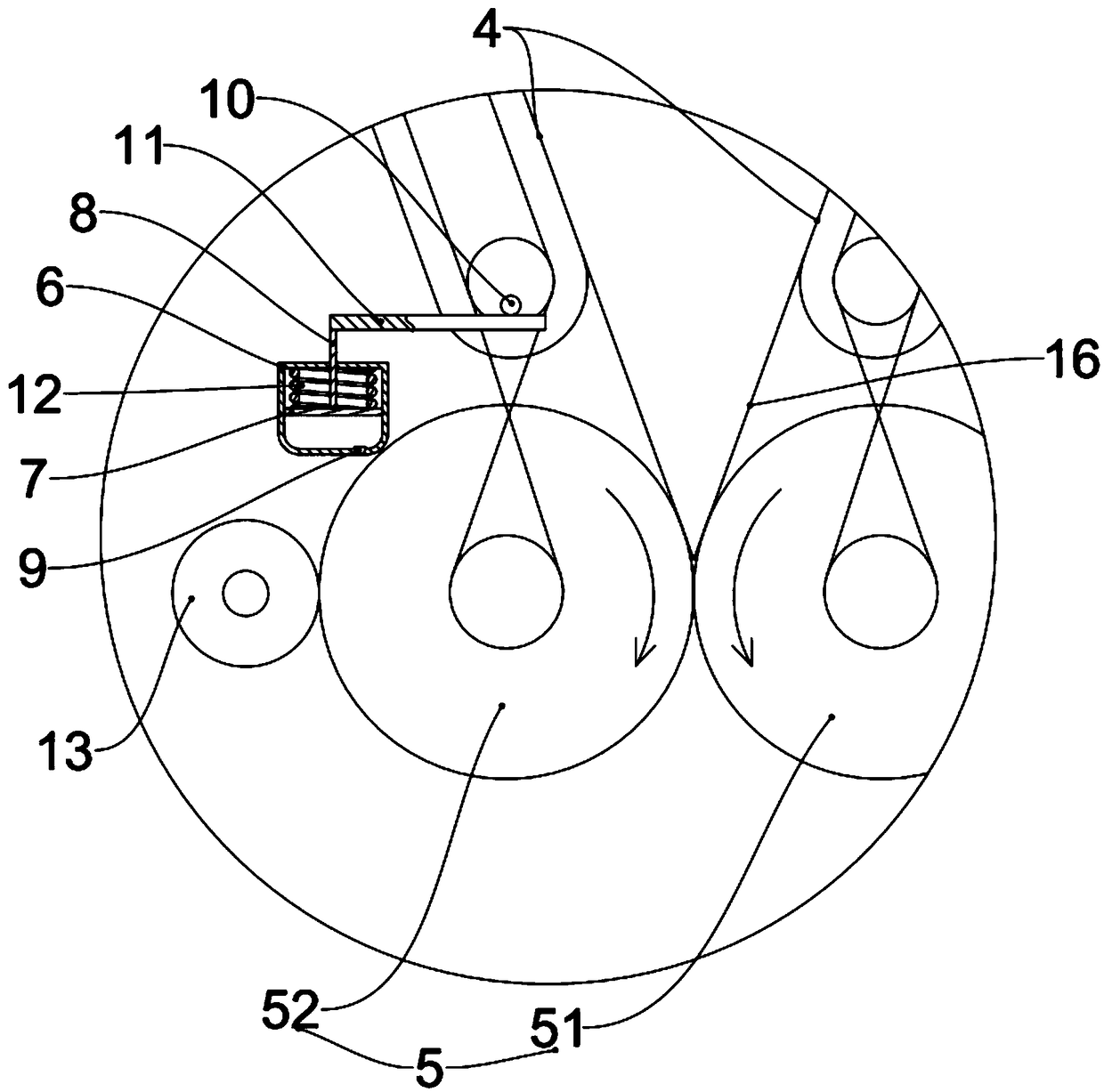

[0033] The reference signs in the drawings of the description include: frame 1, extruder 2, right-angle head 21, air-cooled water-cooled device 3, cooling air ring 31, cooling water ring 32, top belt line 4, traction roller 5, passive Rubber roller 51, active chrome-plated steel roller 52, spray barrel 6, slide plate 7, slide rod 8, rubber block 9, pressure column 10, pressure plate 11, spring 12, cleaning roller 13, guide roller 14, winding device 15, film tube 16.

[0034] The embodiment is basically as figure 1 and figure 2 Shown:

[0035] A blow molding processing method of a CPP film, the production and processing method needs to use a blow molding processing mechanism of the CPP film, the blow molding processing mechanism of the CPP film includes a frame 1 and an extruder 2, the extruder 2 is equipped with Right-angle machine head 21, air-cooled water-cooling device 3 is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com