Automatic shell cutting machine and shell cutting method thereof

A shell cutting machine and automatic technology, applied in the field of jigs, to achieve the effects of avoiding damage, improving secondary utilization, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

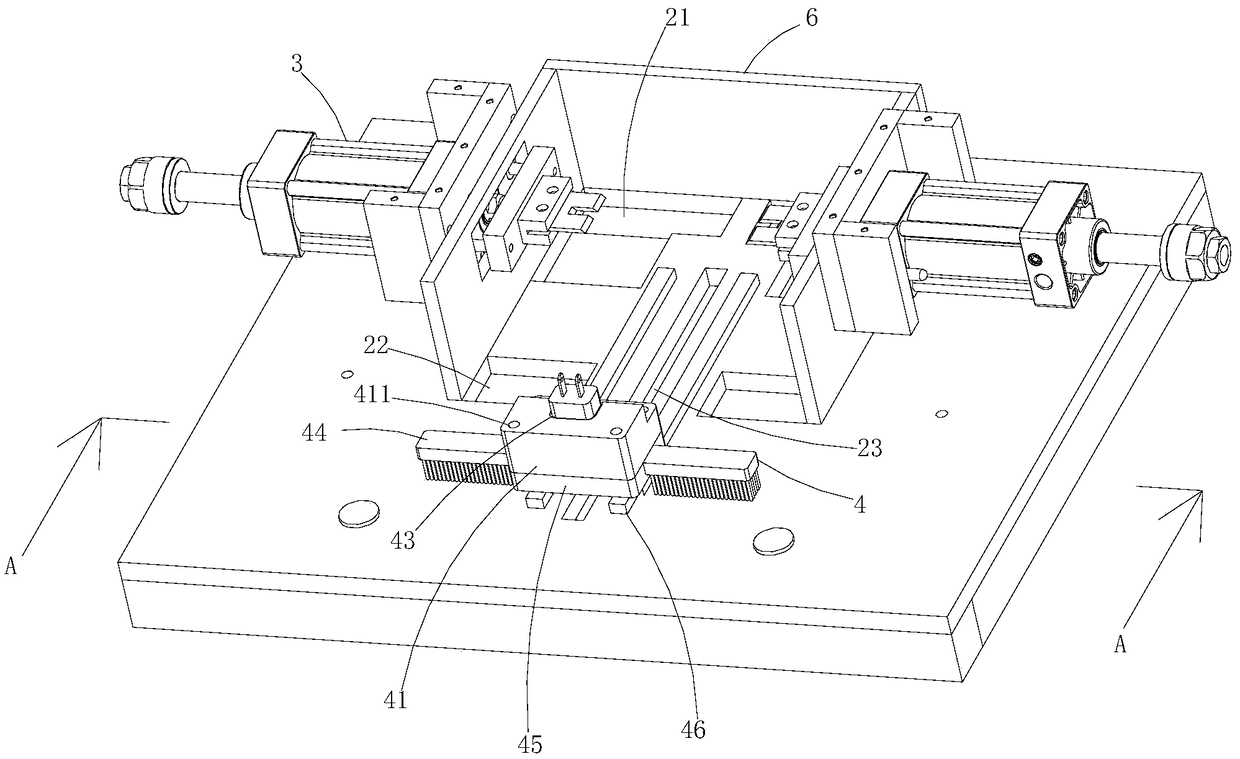

[0042] Such as image 3 and Figure 4 As shown, it is the first embodiment of the conveying mechanism 4 of the present invention, which includes a fixed seat 41 and a second driving device 42 that drives the fixed seat 41 to move linearly on the surface of the operating table 2, and the fixed seat 41 is fixed on the second On the driving device 42; the fixing seat 41 is provided with a fixing groove 43 for fixing defective products.

[0043] The second driving device 42 is a second power cylinder, including a second piston rod 421 and a second cylinder body 422, and the second piston rod 421 is connected to the fixed seat 41; specifically, as image 3 As shown, a through groove 23 is provided at the center of the protective cover 6 on the operating table 2, and the fixed seat 41 is connected and fixed to the front end of the second piston rod 421 through a T-shaped slider 45 extending from the bottom to the through groove 23, The fixed seat 41 is provided with a fixed seat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com