Rare-earth ore beneficiation method

A beneficiation method and rare earth ore technology, which are applied in flotation, solid separation and other directions, can solve the problems of low recovery rate, rare earth grade and high recovery rate, and low technology, so as to improve rare earth grade, high recovery rate and purity, and improve The effect of concentrate purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

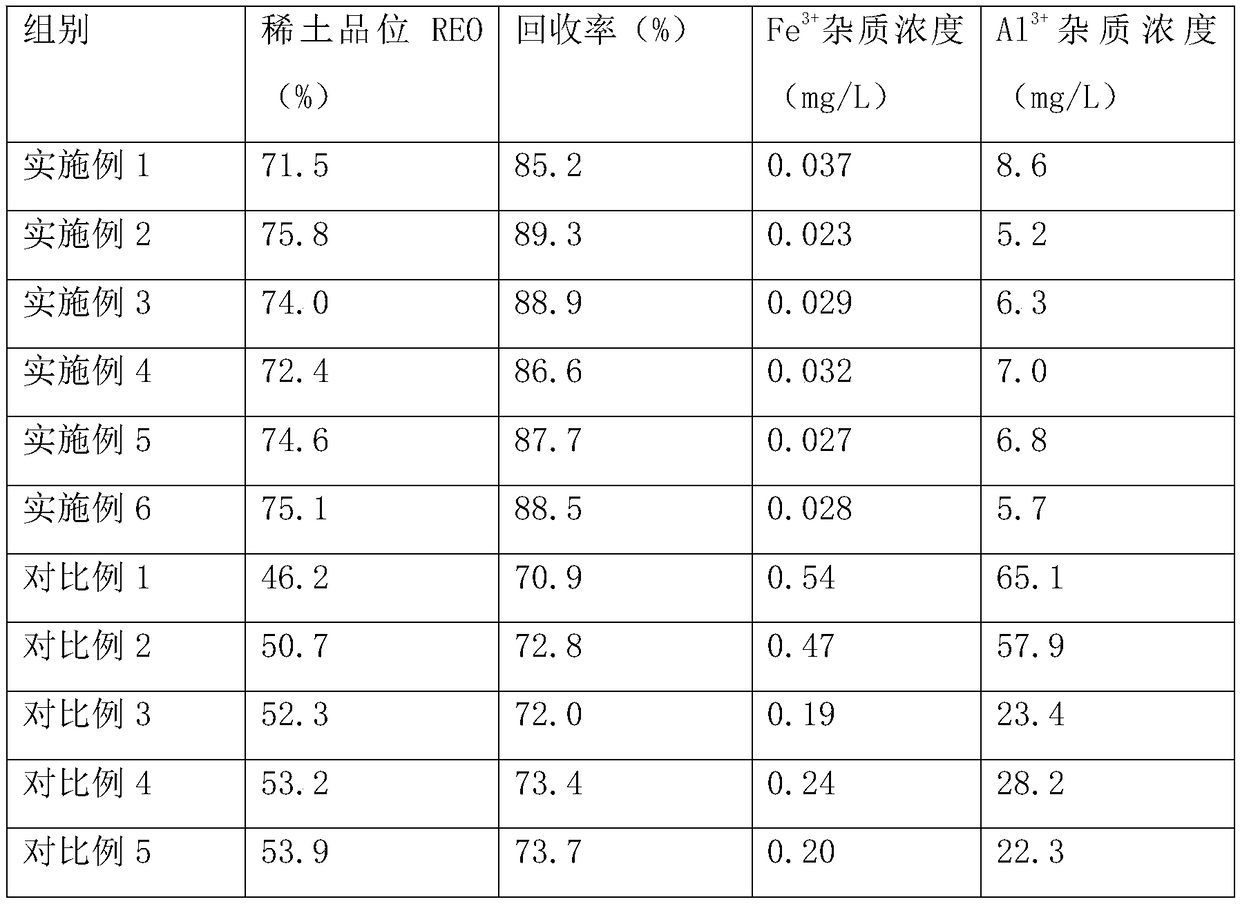

Examples

Embodiment 1

[0042] S1. Crush the rare earth ore in the continental channel in Dechang, Sichuan, grind the ore to a fineness of -0.045mm, accounting for 82% of the total weight, and then perform cyclone desliming and classification to obtain sand and overflow. Take 100kg of sand and add water for adjustment The mass concentration of slurry to mortar is 50%;

[0043] S2, add 150gNaOH solid, 580g water glass, and 120g alkyl hydroxamic acid and the kerosene of 140g to the grit settling after pulping, carry out rough flotation for the first time for 5 minutes, obtain a rough flotation concentrate and a rough Flotation tailings;

[0044] S3, adding 70g of alkyl hydroxamic acid to the tailings of the primary rough flotation, and performing the second rough flotation for 1 minute to obtain the concentrate of the second rough flotation and the tailings of the second rough flotation;

[0045] S4. Add 30 g of alkyl hydroxamic acid to the tailings of the secondary rough flotation, and perform the th...

Embodiment 2

[0050] S1. Crush the rare earth ore in the continental channel in Dechang, Sichuan, grind the ore to a fineness of -0.045mm, accounting for 85% of the total weight, and then perform cyclone desliming and classification to obtain grit and overflow. Take 100kg of grit and add water for adjustment The mass concentration of slurry to mortar is 55%;

[0051] S2, add 165g NaOH solid, 600g water glass, and 130g alkyl hydroxamic acid and 150g diesel oil to the settling sand after pulping, carry out rough flotation for the first time for 8 minutes, obtain a rough flotation concentrate and a rough flotation Tailings;

[0052] S3, adding 80g of alkyl hydroxamic acid to the tailings of the primary rough flotation, and performing the second rough flotation for 3 minutes to obtain the concentrate of the second rough flotation and the tailings of the second rough flotation;

[0053] S4, adding 40g of alkyl hydroxamic acid to the tailings of the secondary rough flotation, and carrying out th...

Embodiment 3

[0058] S1. Crush the rare earth ore in the continental channel in Dechang, Sichuan, grind the ore to a fineness of -0.045mm, accounting for 88% of the total weight, and then carry out cyclone desliming and classification to obtain sand settling and overflow. Take 100kg of sand settling and add water for adjustment The mass concentration of slurry to mortar is 60%;

[0059] S2, add 180g NaOH solid, 620g water glass, and 140g alkyl hydroxamic acid and 160g kerosene to the settling sand after slurry adjustment, carry out the rough flotation for the first time for 10 minutes, obtain a rough flotation concentrate and a rough flotation Tailings;

[0060] S3, adding 90g of alkyl hydroxamic acid to the tailings of the primary rough flotation, and performing the second rough flotation for 5 minutes to obtain the concentrate of the second rough flotation and the tailings of the second rough flotation;

[0061] S4, adding 50g of alkyl hydroxamic acid to the tailings of the secondary rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com