Female animal estrus stimulating superfine powder and method for preparing same

An aphrodisiac powder and ultra-micro technology, which is applied in powder delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problems of low litter rate, low estrus rate, and high probability of miscarriage, and achieve easy storage and use, Reduce sensitivity and solve the effect of low estrus rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

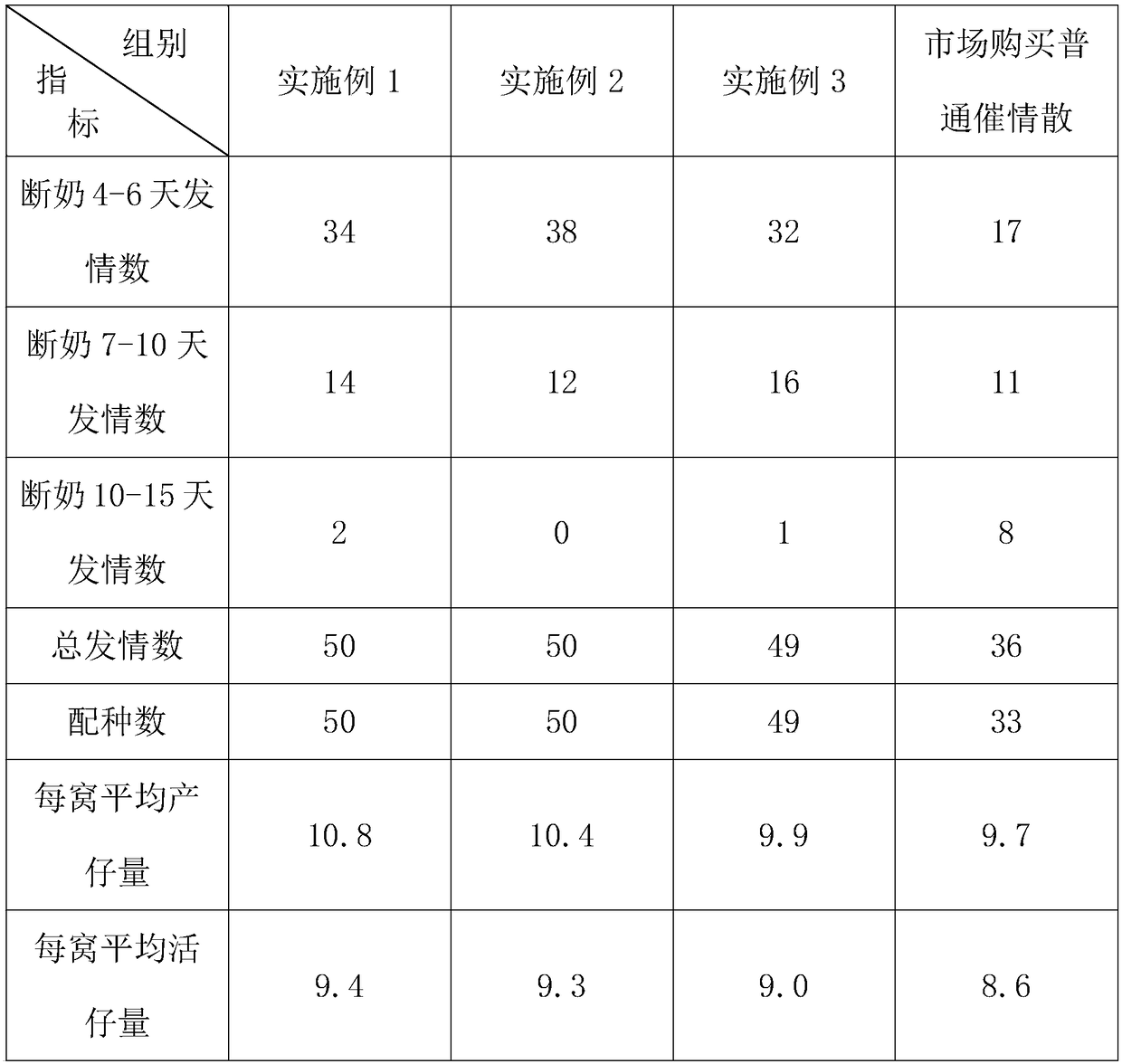

Examples

Embodiment 1

[0029] A kind of mother animal aphrodisiac powder superfine powder, its preparation raw material comprises 10 parts of epimedium, 5 parts of actinolite (wine quenching), 3 parts of angelica, 3 parts of Cyperus cyperi, 3 parts of motherwort, 1 part of cornus in parts by weight Meat, 1 portion of Limedong, 1 portion of Pearl Ginseng, 1 portion of Polygonatum odoratum.

[0030] The preparation method of the above-mentioned female animal aphrodisiac powder superfine powder, the steps include

[0031] Step 1. Soak each raw material in deionized water at 35°C, and perform ultrasonic treatment. The power of ultrasonic treatment is 300W, the frequency is 30kHz, and the time is 10min;

[0032] Step 2. After ultrasonic treatment, dry each raw material to a moisture content of 25%, cut into 0.5cm long sections, then dry to a moisture content of 7%, then coarsely powder to 40 mesh, and mix evenly;

[0033] Step 3. Add cellulase to the coarse powder for enzyme activation treatment. The en...

Embodiment 2

[0036] An ultrafine powder of mother animal aphrodisiac powder, the preparation raw materials include 15 parts of epimedium, 8 parts of actinolite (wine quenching), 6 parts of angelica, 5 parts of Cyperus cyperi, 4 parts of motherwort, and 3 parts of cornus by weight. , 3 parts of Limedong, 2 parts of Pearl Ginseng, and 2 parts of Polygonatum Polygonatum.

[0037] The preparation method of the above-mentioned female animal aphrodisiac powder superfine powder, the steps include

[0038] Step 1. Soak each raw material in deionized water at 38°C, and perform ultrasonic treatment. The power of ultrasonic treatment is 300W, the frequency is 30kHz, and the time is 15min;

[0039] Step 2. After ultrasonic treatment, dry each raw material to a moisture content of 27%, cut into 0.8cm long sections, then dry to a moisture content of 8%, and then coarsely powder to 45 mesh, and mix evenly;

[0040] Step 3. Add cellulase to the coarse powder for enzyme activation treatment. The enzyme ac...

Embodiment 3

[0043] A kind of mother animal aphrodisiac powder superfine powder, its preparation raw material comprises 20 parts of epimedium, 10 parts of actinolite (wine quenching), 10 parts of angelica, 8 parts of Cyperus cyperi, 5 parts of motherwort, and 5 parts of cornus by weight. Meat, 5 parts of Limedong, 4 parts of pearl ginseng, and 3 parts of Polygonatum odoratum.

[0044] The preparation method of the above-mentioned female animal aphrodisiac powder superfine powder, the steps include

[0045] Step 1. Soak each raw material in deionized water at 40°C, and perform ultrasonic treatment. The power of ultrasonic treatment is 300W, the frequency is 30kHz, and the time is 20min;

[0046] Step 2. After ultrasonic treatment, dry each raw material to a moisture content of 30%, cut into 1cm long sections, then dry to a moisture content of 10%, and then coarsely powder to 50 mesh, and mix evenly;

[0047] Step 3. Add cellulase to the coarse powder for enzyme activation treatment. The en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Enzyme activity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com