Stain-resistant nanometer garment fabric and preparation method thereof

A nano-technology, anti-fouling technology, applied in the field of clothing fabrics, can solve the problems of reduced anti-fouling performance, reduced anti-fouling performance, etc., to achieve the effect of improving anti-fouling ability, high hydrophobic anti-fouling performance, and achieving anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

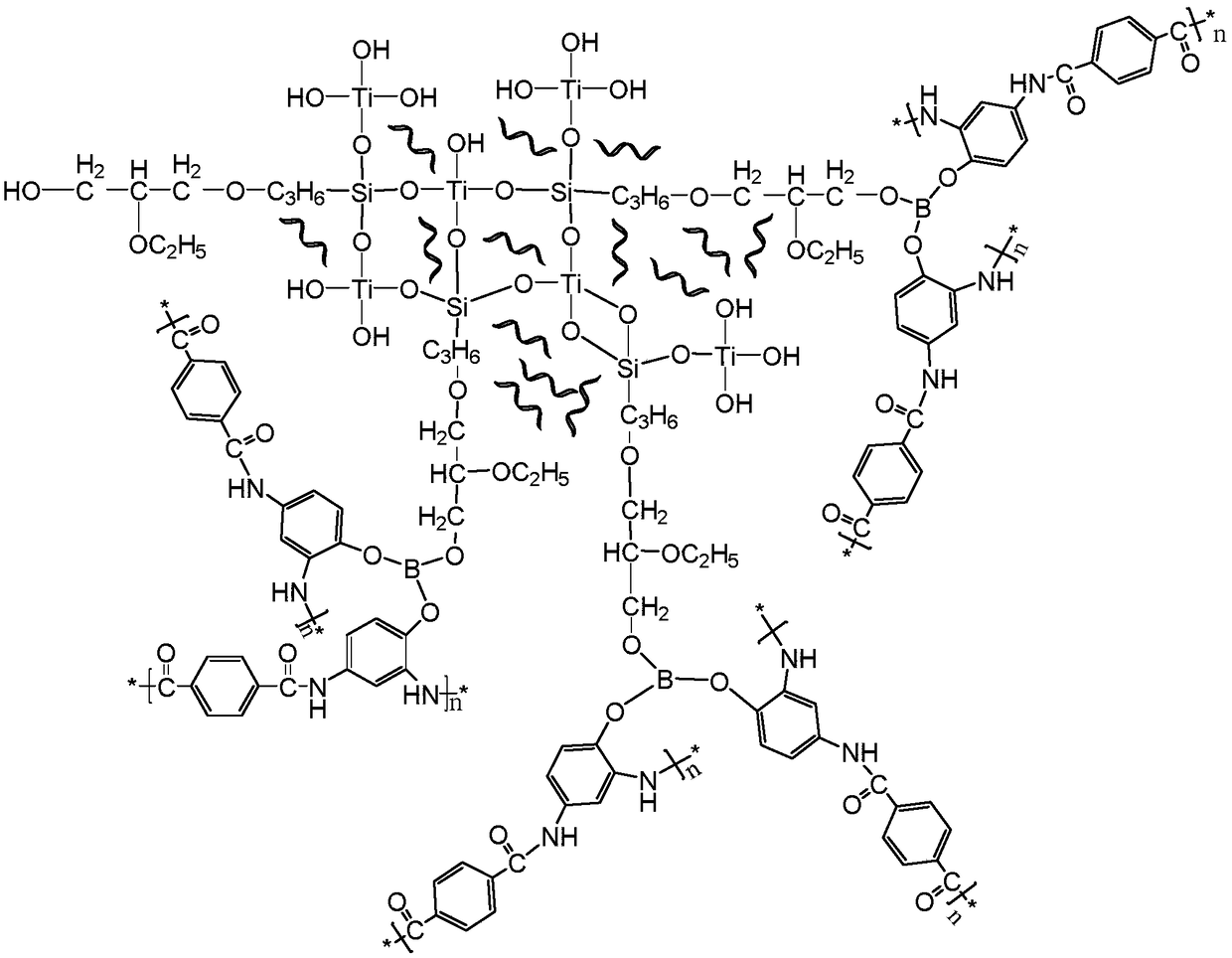

[0033] The specific preparation process of composite blended cellulose acetate is as follows:

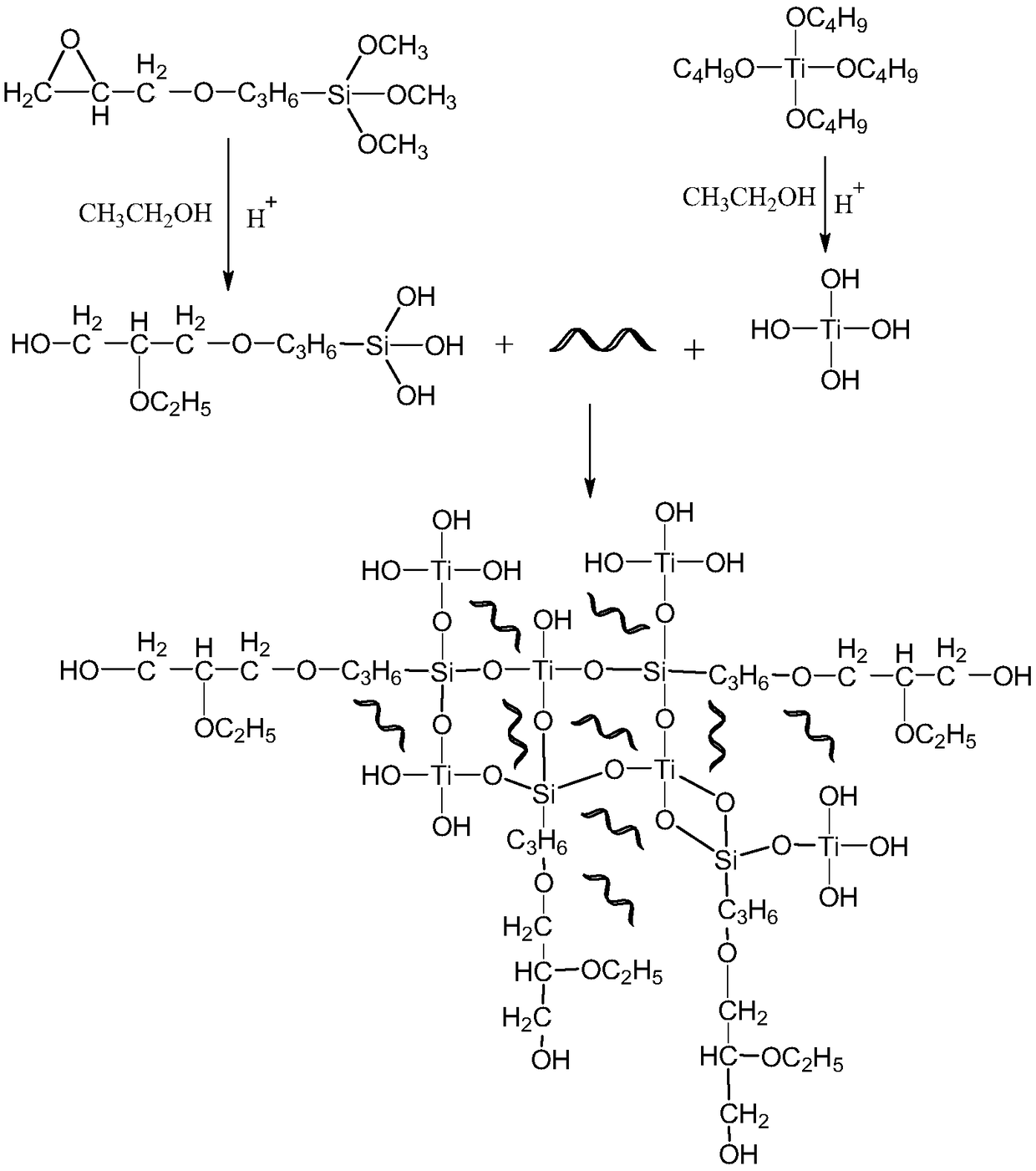

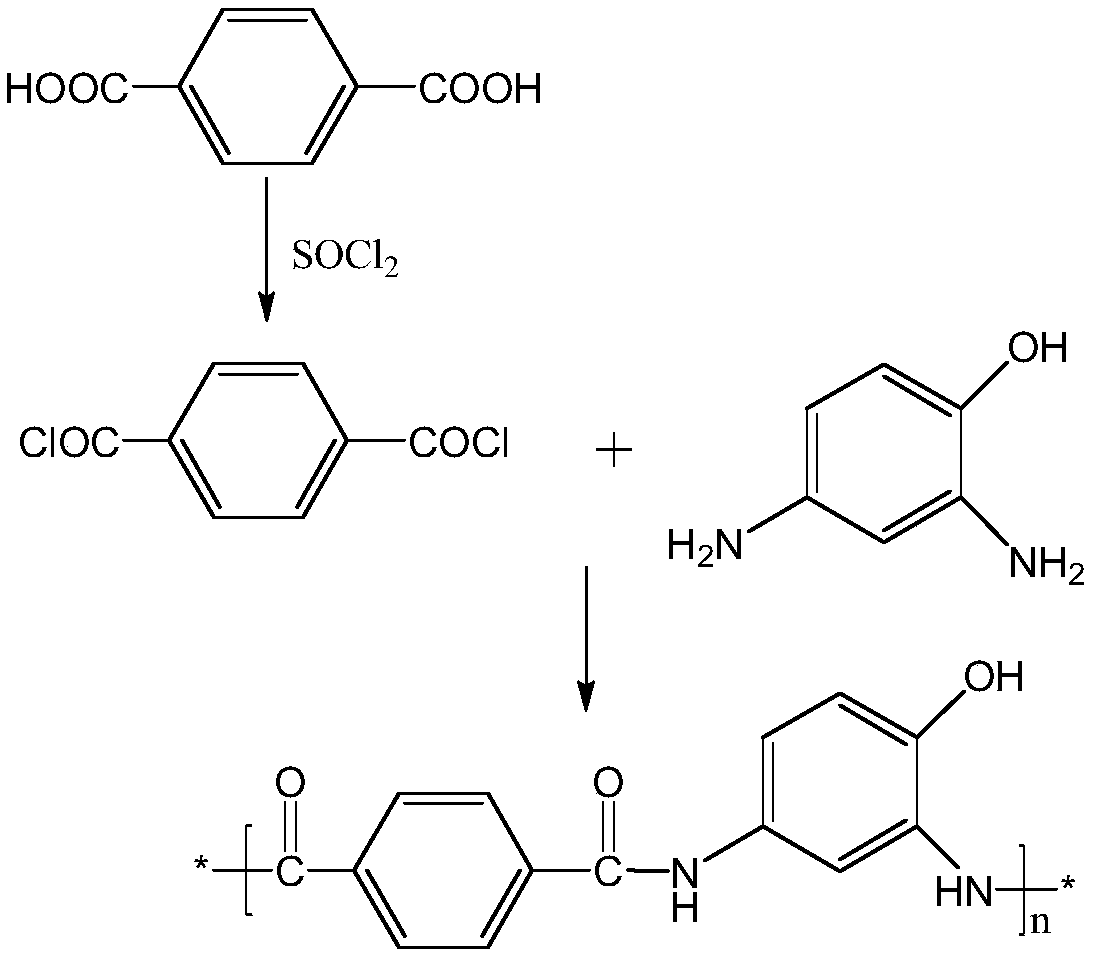

[0034] Step 1: Add 1kg of γ-(2,3-glycidoxy)propyltrimethoxysilane and 10L of absolute ethanol into the reaction vessel, raise the temperature to 60°C for reflux reaction for 2 hours, and add hydrochloric acid to it at the same time to control the concentration of the reaction solution. pH=2, obtain silica gel solution;

[0035] Step 2: Dissolve 1kg of cellulose acetate in 10L of acetone, add the dissolved cellulose acetate solution into the reaction vessel, add 5.6kg of silica colloid solution and 0.3kg of dibutyltin dilaurate to it at the same time, stir and mix and heat up to 70°C , then add 0.61kg tetrabutyl titanate to the reaction vessel, and add hydrochloric acid therein to adjust the pH=3 of the solution, control the temperature to keep the reflux reaction for 4-5h, and obtain a viscous composite fiber colloid solution;

[0036] Step 3: Pour the viscous composite fiber collo...

Embodiment 2

[0043] The specific preparation process of composite blended cellulose acetate is as follows:

[0044] Step 1: Add 1kg of γ-(2,3-glycidoxy)propyltrimethoxysilane and 12L of absolute ethanol into the reaction vessel, raise the temperature to 60°C for reflux reaction for 2 hours, and add hydrochloric acid to it at the same time to control the concentration of the reaction solution. pH=2, obtain silica gel solution;

[0045] Step 2: Dissolve 1kg of cellulose acetate in 10L of acetone, add the dissolved cellulose acetate solution into the reaction vessel, add 5.8kg of silica colloid solution and 0.3kg of dibutyltin dilaurate to it at the same time, stir and mix, then heat up to 70°C , then add 0.63kg tetrabutyl titanate to the reaction vessel, and add hydrochloric acid therein to adjust the pH=3 of the solution, control the temperature to keep the reflux reaction for 4-5h, and obtain a viscous composite fiber colloid solution;

[0046] Step 3: Pour the viscous composite fiber col...

Embodiment 3

[0053] The specific preparation process of composite blended cellulose acetate is as follows:

[0054] Step 1: Add 1kg of γ-(2,3-glycidoxy)propyltrimethoxysilane and 10L of absolute ethanol into the reaction vessel, raise the temperature to 60°C for reflux reaction for 2 hours, and add hydrochloric acid to it at the same time to control the concentration of the reaction solution. pH=2, obtain silica gel solution;

[0055] Step 2: Dissolve 1kg of cellulose acetate in 10L of acetone, add the dissolved cellulose acetate solution into the reaction vessel, add 3.5kg of silica colloid solution and 0.3kg of dibutyltin dilaurate to it at the same time, stir and mix, then heat up to 70°C , then add 0.41kg tetrabutyl titanate to the reaction vessel, and add hydrochloric acid therein to adjust the pH=3 of the solution, control the temperature to keep the reflux reaction for 4-5h, and obtain a viscous composite fiber colloid solution;

[0056] Step 3: Pour the viscous composite fiber col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com