A method for increasing the bulkiness and aroma components of reconstituted tobacco leaves

A technology of aromatizing components and reconstituted tobacco leaves, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of not being able to participate in cigarette burning and not being enough, and achieve the effect of improving aroma quality, aromatizing components, and internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

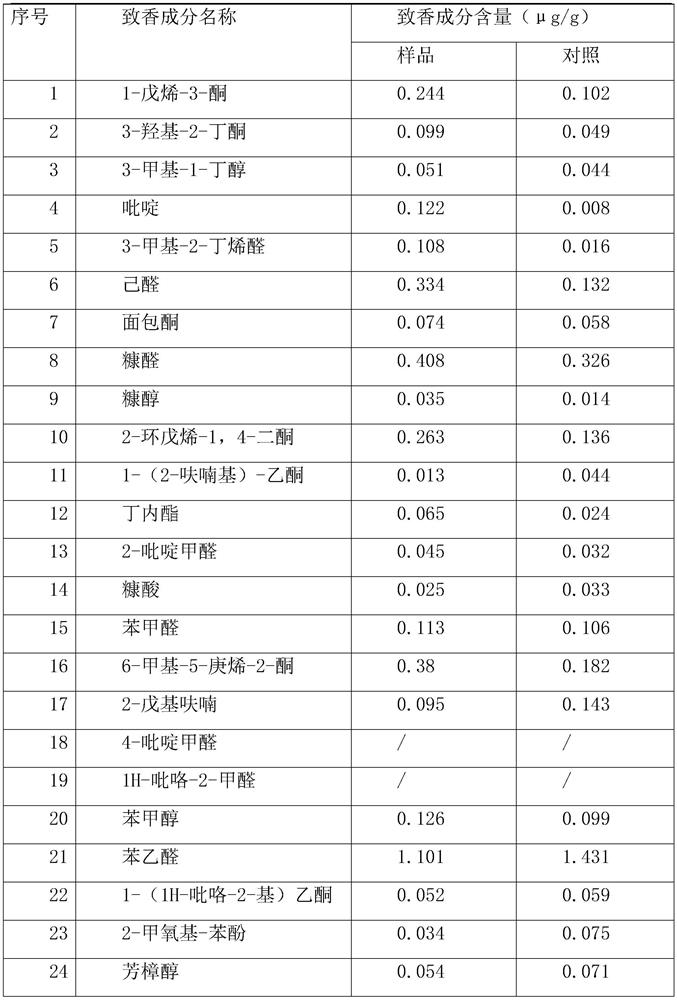

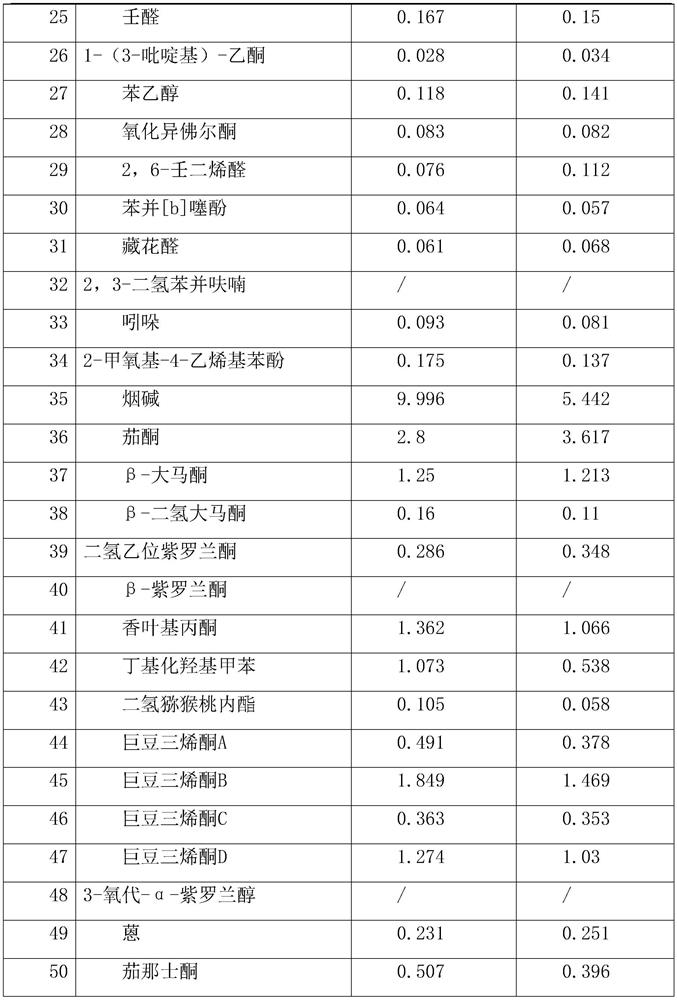

[0026] The steps for improving the bulkiness and aroma components of reconstituted tobacco leaves are as follows:

[0027] 1. The threshed red-cured tobacco stems are expanded by a microwave expansion process, and then granulated to make microwave expanded stems with a particle size of 40-60 mesh.

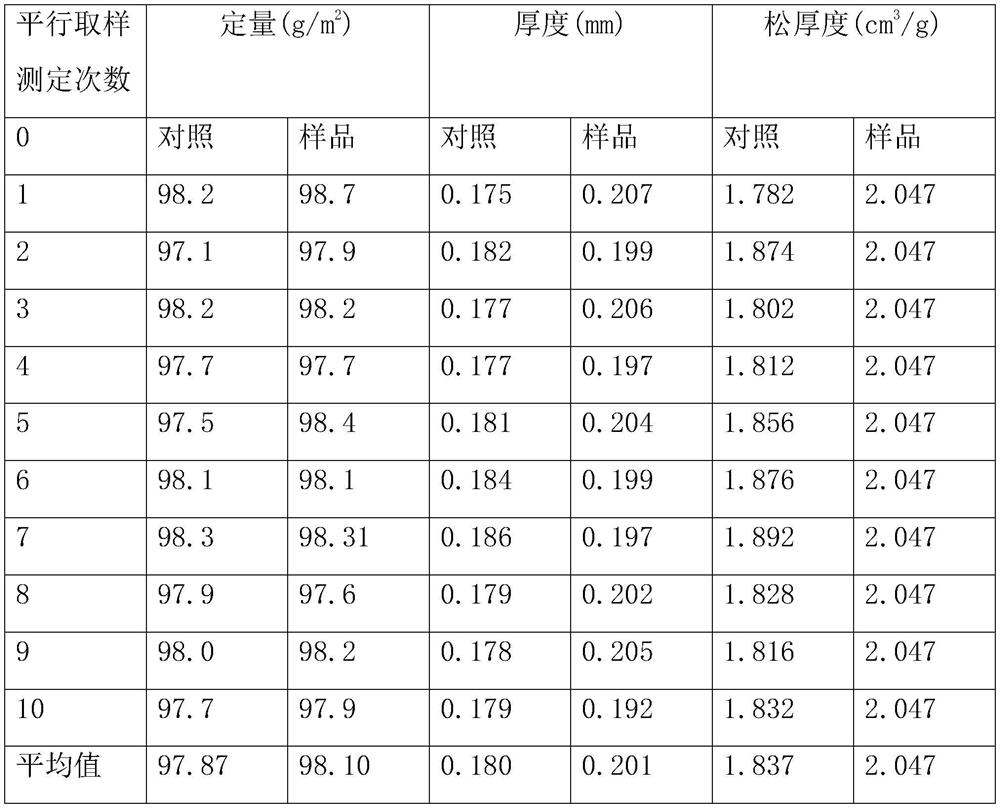

[0028] 2. According to the tobacco raw material formula and production process of the reconstituted tobacco leaves by the papermaking method, the tobacco raw material is extracted and solid-liquid separated, and the solid part of the extracted tobacco raw material is made into tobacco pulp according to the pulping process (tobacco pulp refers to dry tobacco pulp); microwave expanded stalk grains are added to the mixture of tobacco pulp and bleached softwood pulp in the forebay to prepare paper base; the weight ratio of the tobacco pulp, bleached softwood pulp and microwave expanded stalk grains is 70: 20:10.

[0029] 3. The paper base is continued to be coated, dried, and sliced ...

Embodiment 2

[0036] The steps for improving the bulkiness and aroma components of reconstituted tobacco leaves are as follows:

[0037] 1. Recycling waste smoke from the dry ice expanded shredded tobacco production line after screening, crushing and screening to prepare dry ice expanded tobacco powder particles of 60-80 mesh.

[0038] 2. According to the tobacco raw material formula and production process of the reconstituted tobacco leaf by the papermaking method, the tobacco raw material is extracted and solid-liquid separated, and the solid part of the extracted tobacco raw material is made into tobacco pulp according to the pulping process; The pulp box is added to the mixture of tobacco pulp and unbleached softwood pulp to prepare a paper base; the weight ratio of the tobacco pulp, unbleached softwood pulp and dry ice expanded tobacco powder particles is 66:22:12.

[0039] 3. The paper base is continued to be coated, dried, and sliced according to the conventional procedures of reco...

Embodiment 3

[0056] The steps for improving the bulkiness and aroma components of reconstituted tobacco leaves are as follows:

[0057] 1. Co-expand the fennel stalks with microwave / superheated steam, and then granulate to make plant expansion granules with a particle size of 50-60 meshes. This granule is combined with the dry ice expanded smoke particles described in Example 2. 40:60 weight ratio mixed evenly to form mixed expanded particles.

[0058] 2. According to the tobacco raw material formula (wherein the weight ratio of flue-cured tobacco raw material and sun-cured tobacco raw material is 40:60) and the production process of the reconstituted tobacco leaf by the papermaking method, the tobacco raw material is extracted, and the solid-liquid separation is carried out, and the solid part of the extracted tobacco raw material is prepared according to the production process. Pulp technology is made into tobacco pulp; the mixed expanded particles are added to the mixture of tobacco pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com