Oil-flavored yellow sour soup and preparation method thereof

A yellow acid and oil-flavored technology, which is applied in the direction of oil-containing food ingredients, food ingredients as odor improvers, food ingredients as taste improvers, etc., to achieve the effects of improving immunity, strong spicy smell, and shortening fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

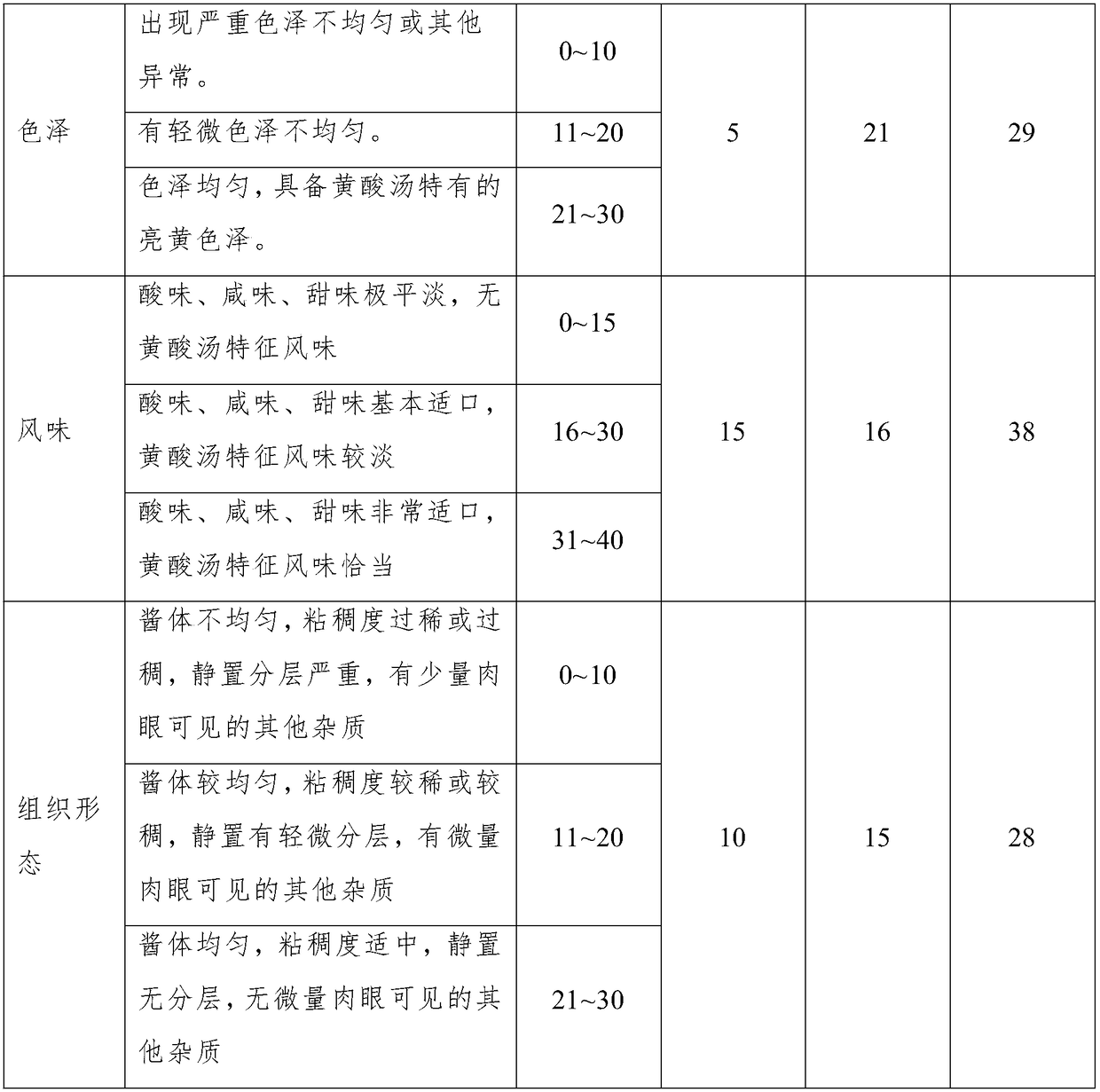

Examples

Embodiment 1

[0032] The oil-flavored yellow sour soup of this embodiment is made of the following raw materials in mass fractions: 21% pumpkin, 9% yellow tomato, 6% salt, 3% red sour soup fermentation liquid, 1.2% small squeezed oil, and 2.8% soybean oil , 1.5% monosodium glutamate, 0.8% white granulated sugar, 0.3% wood ginger oil, and the balance is water.

[0033] The preparation method of above-mentioned oily yellow sour soup, comprises the following steps:

[0034] Step 1, the pumpkins are picked, peeled, seeded, cleaned, cut, and crushed in sequence, and then mixed with water to make raw material A; the yellow tomatoes are washed and crushed in sequence, and then mixed with water to make raw material B;

[0035] Step 2, mix raw material A and raw material B obtained in step 1, add salt and red sour soup fermented liquid, after mixing and stirring for 10 minutes, seal anaerobic fermentation for 3 months, obtain semi-finished product C; described red sour soup fermented liquid The prepa...

Embodiment 2

[0049] The oil-flavored yellow sour soup of this embodiment is made from the following raw materials in mass fraction: 25.5% of pumpkin, 6% of small yellow tomato, 4% of salt, 1% of red sour soup fermentation liquid, 0.9% of small squeezed oil, and 2.1% of soybean oil , 1% monosodium glutamate, 0.6% white granulated sugar, 0.1% wood ginger oil, and the balance is water.

[0050] The preparation method of above-mentioned oily yellow sour soup, comprises the following steps:

[0051] Step 1, the pumpkins are picked, peeled, seeded, cleaned, cut, and crushed in sequence, and then mixed with water to make raw material A; the yellow tomatoes are washed and crushed in sequence, and then mixed with water to make raw material B;

[0052] Step 2, mix raw material A and raw material B obtained in step 1, add salt and red sour soup fermentation liquid, after mixing and stirring for 12.5 minutes, seal anaerobic fermentation for 1 month, and obtain semi-finished product C; the red sour sou...

Embodiment 3

[0063] The oil-flavored yellow sour soup of the present embodiment is made of the following raw materials in mass fraction: 33% of pumpkin, 12% of small yellow tomato, 4% of table salt, 1% of red sour soup fermentation liquid, 1.5% of small squeezed oil, and 3.5% of soybean oil , 1% monosodium glutamate, 0.6% white granulated sugar, 0.1% wood ginger oil, and the balance is water.

[0064] The preparation method of above-mentioned oily yellow sour soup, comprises the following steps:

[0065] Step 1, the pumpkins are picked, peeled, seeded, cleaned, cut, and crushed in sequence, and then mixed with water to make raw material A; the yellow tomatoes are washed and crushed in sequence, and then mixed with water to make raw material B;

[0066] Step 2, mix raw material A and raw material B obtained in step 1, add salt and red sour soup fermented liquid, after mixing and stirring for 15 minutes, seal anaerobic fermentation for 2 months, obtain semi-finished product C; described red ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com