Honey peanut and production technology thereof

A production process and peanut technology, applied in food science, food coating, application and other directions, can solve problems such as easy falling off and uneven coating, and achieve the effect of simple preparation process, ensuring appearance consistency, and promoting human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

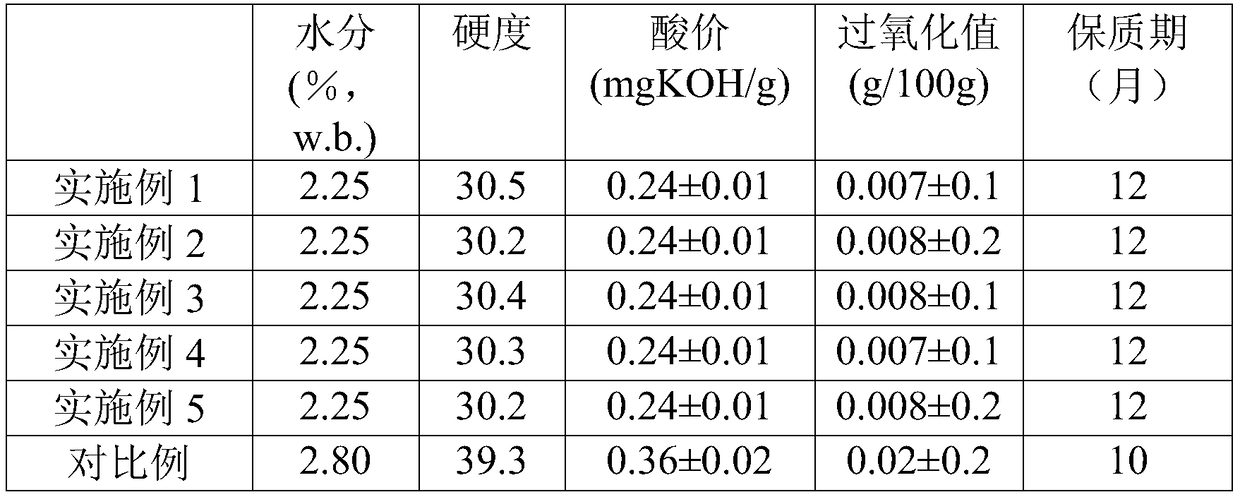

Examples

Embodiment 1

[0037] The preparation process of honey peanuts is as follows: step (1): weigh 900kg of peanut kernels, 63kg of water, 0.45kg of xanthan gum, 2.7kg of maltose syrup, 244.85kg of white granulated sugar, 9kg of honey, and 10kg of edible salt;

[0038] Step (2): Mix the above-mentioned xanthan gum, maltose syrup, white granulated sugar, honey and water, stir evenly, and prepare a coating solution for later use, wherein the temperature of the water is 60°C, and the water, xanthan gum, and maltose syrup , The weight ratio of white sugar and honey is 63:0.45:2.7:14.85:9;

[0039] Step (3): Mix the above-mentioned white granulated sugar and edible salt, stir evenly, and prepare the front powder for later use;

[0040]Step (4): Put the peanut kernels in the wrapping tube, and the inner wall of the wrapping tube is arranged with triangular protrusions at equal intervals along the horizontal and vertical sides of the barrel, and the adjacent triangular protrusions are fixed with elastic...

Embodiment 2

[0047] The preparation process of honey peanuts is as follows: Step (1): Weigh 1000kg of peanut kernels, 70kg of water, 0.5kg of xanthan gum, 3kg of maltose syrup, 276.5kg of white granulated sugar, 10kg of honey, and 13kg of edible salt;

[0048] Step (2): Mix the above-mentioned xanthan gum, maltose syrup, white granulated sugar, honey and water, stir evenly, and prepare a coating solution for later use, wherein the temperature of the water is 65°C, and the water, xanthan gum, and maltose syrup , The weight ratio of white sugar and honey is 70:0.5:3:16.5:10;

[0049] Step (3): Mix the above-mentioned white granulated sugar and edible salt, stir evenly, and prepare the front powder for later use;

[0050] Step (4): Put the peanut kernels in the wrapping tube, and the inner wall of the wrapping tube is arranged with triangular protrusions at equal intervals along the horizontal and vertical sides of the barrel, and the adjacent triangular protrusions are fixed with elastic she...

Embodiment 3

[0057] The preparation process of honey peanuts is as follows: Step (1): Weigh 1100kg of peanut kernels, 77kg of water, 0.55kg of xanthan gum, 3.3kg of maltose syrup, 298.3kg of white granulated sugar, 11kg of honey, and 15kg of edible salt;

[0058] Step (2): Mix the above-mentioned xanthan gum, maltose syrup, white granulated sugar, honey and water, stir evenly, and prepare a coating solution for later use, wherein the temperature of the water is 70°C, and the water, xanthan gum, and maltose syrup , The weight ratio of white sugar and honey is 77:0.55:3.3:18.3:11;

[0059] Step (3): Mix the above-mentioned white granulated sugar and edible salt, stir evenly, and prepare the front powder for later use;

[0060] Step (4): Put the peanut kernels in the wrapping tube, and the inner wall of the wrapping tube is arranged with triangular protrusions at equal intervals along the horizontal and vertical sides of the barrel, and the adjacent triangular protrusions are fixed with elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com