Shifting force detecting, positioning and clamping device of gear pawl lever, and shifting force detection and correction method of gear pawl lever

A technology of positioning clamping and shifting force, which is applied in the direction of measuring device, workpiece clamping device, force/torque/power measuring instrument, etc., can solve the problems of inequal application and different shifting force, and avoid the process long-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

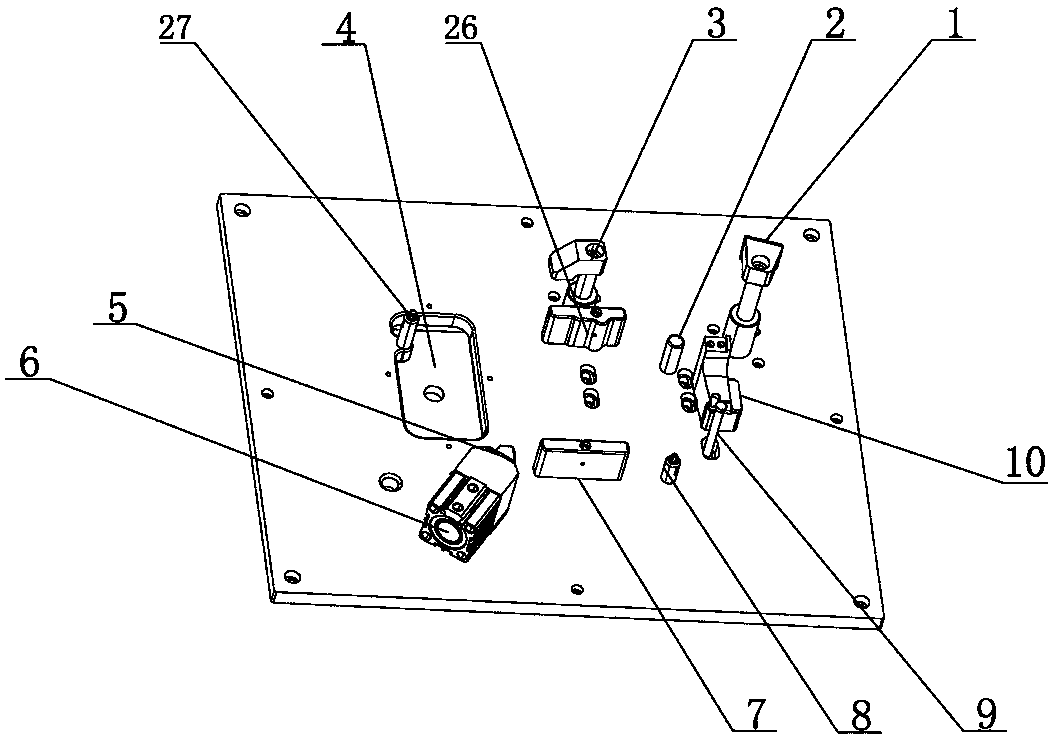

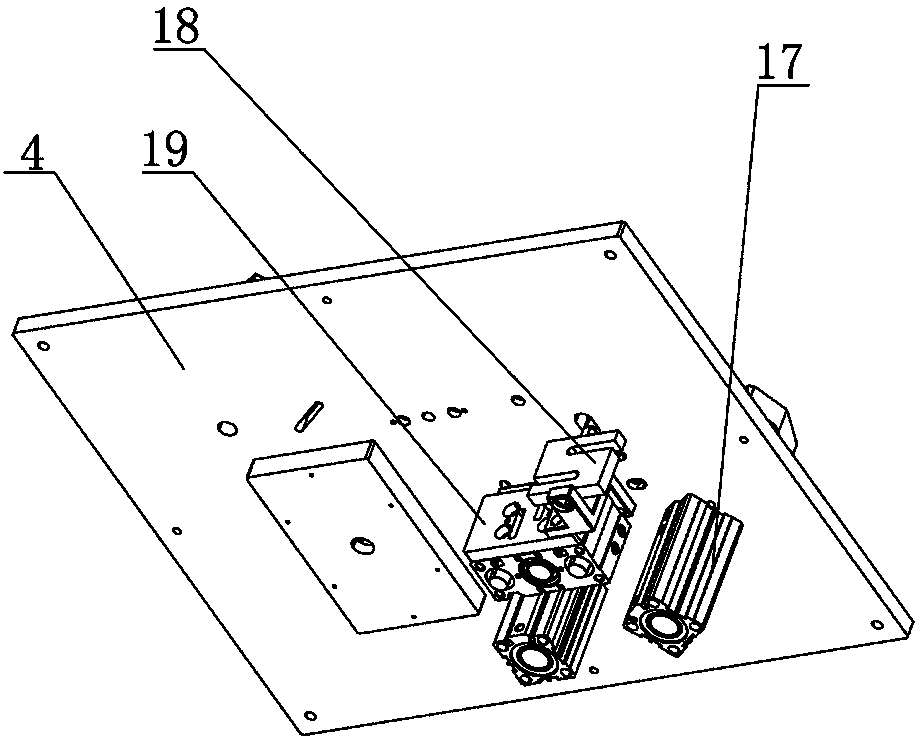

[0041]Put the valve body on the operation platform of the pawl piece selection machine, use the left positioning pin 27, the lower positioning block 7, the upper positioning block 26, the right positioning column 2 and the lower positioning pin 8 on the platform to provide positioning for the valve body assembly , to limit the degree of freedom of the valve body in the horizontal direction. At this time, the shift force test rod 9 is just below the card wheel 24 at the tail end of the pawl spring assembly, and the six variable flow solenoid valves 15 are just located in the concave of the variable flow solenoid valve. In slot 4;

[0042] Press the two start buttons at the same time, the clamping claw 3 of the valve body assembly will rotate clockwise 90° under the action of the lower rotary clamping cylinder 25 and move downward at the same time, pressing the upper part of the valve body, and the valve body assembly pushes the block 5 Driven by the action of the cylinder, move...

Embodiment approach 1

[0045] If the feedback elastic force is within the range of 39.5±0.5N, it is qualified. The pressing claw 3 of the valve body assembly, the clamping claw 1 of the ratchet spring assembly, and the pushing block 5 of the valve body assembly return to the initial position under the action of the corresponding control cylinder. Lift up the valve body assembly and move to the next station;

Embodiment approach 2

[0047] If the feedback elastic force is within the range of 38-39N, if it is unqualified, the pressing claw 3 of the valve body assembly, the clamping claw 1 of the ratchet spring assembly, and the pushing block 5 of the valve body assembly will return to the initial state under the action of the corresponding control cylinder Position, lift the valve body assembly, reduce the adjustment gasket 4.5mm to 4mm, repeat the above test process, the feedback elastic force is within the range of 39.5±0.5N, qualified;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com