Washing machine and water inlet control method thereof

A technology for water inlet control and washing machine, applied in the control device of washing machine, other washing machines, washing devices, etc., can solve the problems of washing machine rust, pollution shock absorber, foam overflowing into the interior of the washing machine, etc., to improve the control effect and guarantee longevity and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

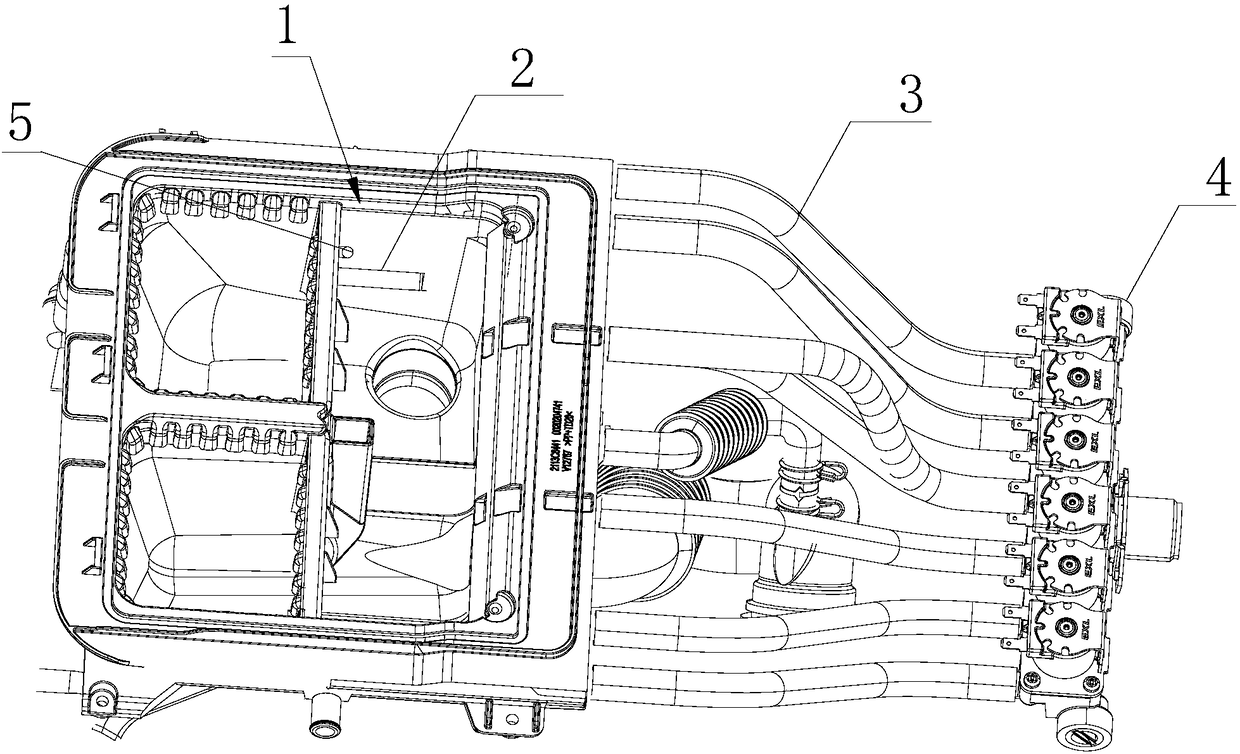

[0047] see figure 1 As shown, this embodiment provides a washing machine, including a water inlet device, the water inlet device includes a water inlet and a water outlet, and the washing machine also includes a foam detection device 5, and the foam detection device 5 passes The measuring signal is transmitted into the water inlet device and the foam height in the water inlet device is determined according to the time of receiving the echo signal. The control device of the washing machine controls the water inlet flow rate of the water inlet device according to the foam height detected by the foam detection device.

[0048] The water inlet device includes a water inlet pipeline and a water storage tank 1 communicated with the water inlet pipeline, and the foam detection device 5 is arranged on the water storage tank 1 and includes a measurement signal transmitting end for transmitting a measurement signal into the water storage tank 1 , the measurement signal transmitting end ...

Embodiment 2

[0055] Embodiment 2 provides a washing machine, including a water inlet device, the water inlet device includes a water inlet and a water outlet, the water inlet is connected to a water source, and the water outlet is connected to the washing chamber of the washing machine, and the washing machine also includes a foam detection device, the foam detection device transmits a measurement signal into the water inlet device and determines the foam height in the water inlet device according to the time of receiving the echo signal, and the control device of the washing machine controls the water inlet according to the foam height detected by the foam detection device water flow to the device.

[0056] The water inlet device includes a water inlet pipeline and a water storage tank 1 communicated with the water inlet pipeline. The water storage tank 1 is used to accommodate the detergent delivery box, and a water inlet valve 4 is arranged on the water inlet pipeline of the washing mach...

Embodiment 3

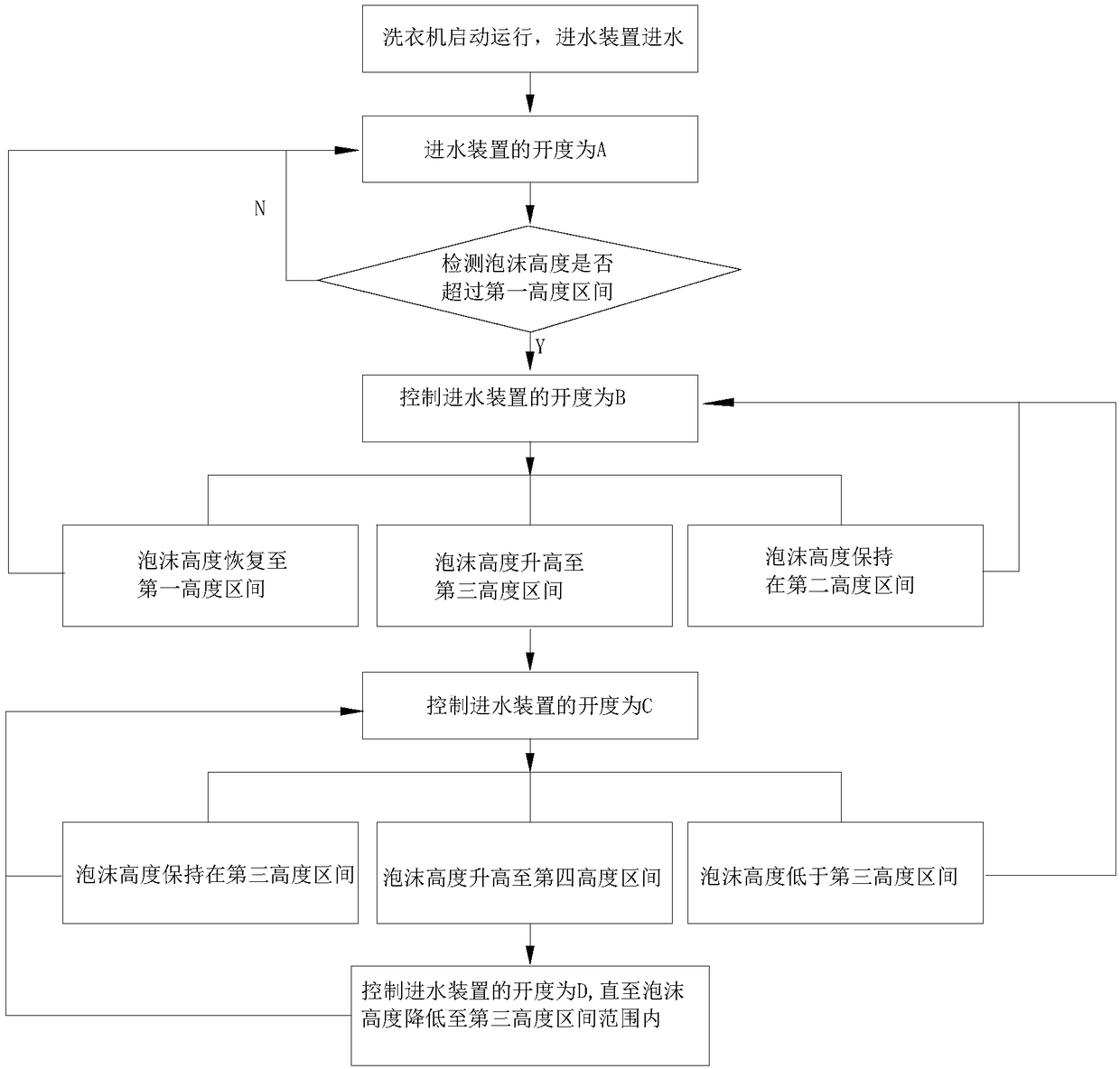

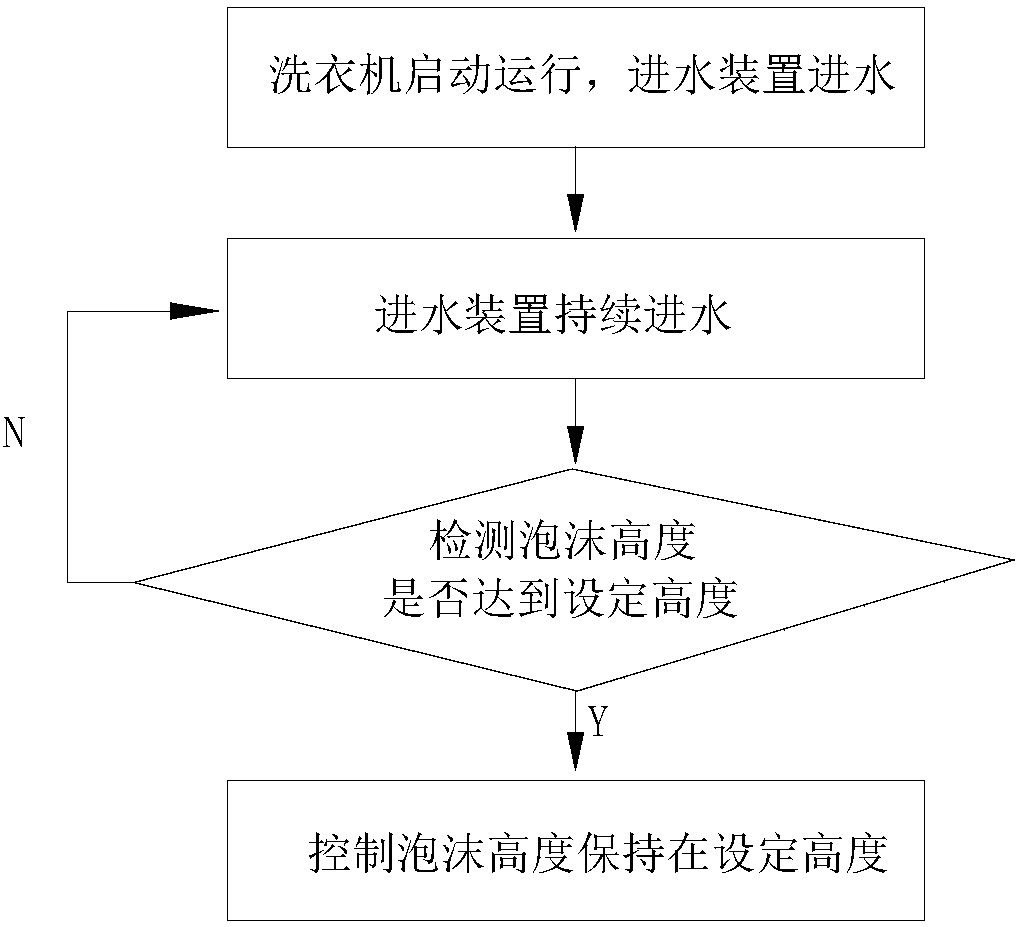

[0065] Embodiment 3 provides a water inlet control method applied to the washing machine in the above embodiment, including: during the water inlet process of the washing machine, the control device controls the water inlet flow rate of the water inlet device according to the foam height detected by the foam detection device 5 , prevent the foam in the water storage tank 1 from overflowing from the overflow port 2.

[0066] Preferably, the foam detection device 5 detects the foam height in real time, and the control device controls the water inlet flow of the water inlet device in real time according to the foam height in the water storage tank 1 detected by the foam detection device 5;

[0067] In the above scheme, because the present invention uses a radar level gauge or an ultrasonic level gauge, it can detect the height of the foam in real time, and can detect foam at any height, so the radar level gauge or the ultrasonic level gauge is used as the foam detection device 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com