Block splicing type PC component universal mold

A general-purpose mold, block-type technology, applied in the direction of molds, mold trays, mold panels, etc., can solve the problems of different degrees of standardization, non-reusability, and poor versatility of prefabricated component molds, and achieve the ability to reuse and expand and upgrade. Guaranteed service life and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

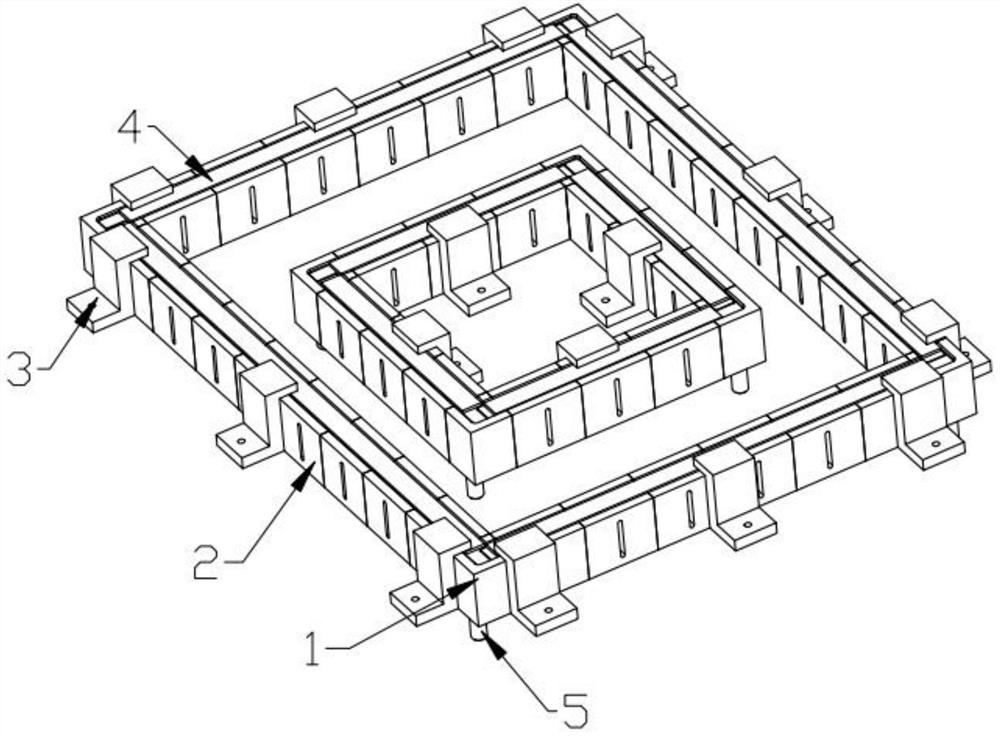

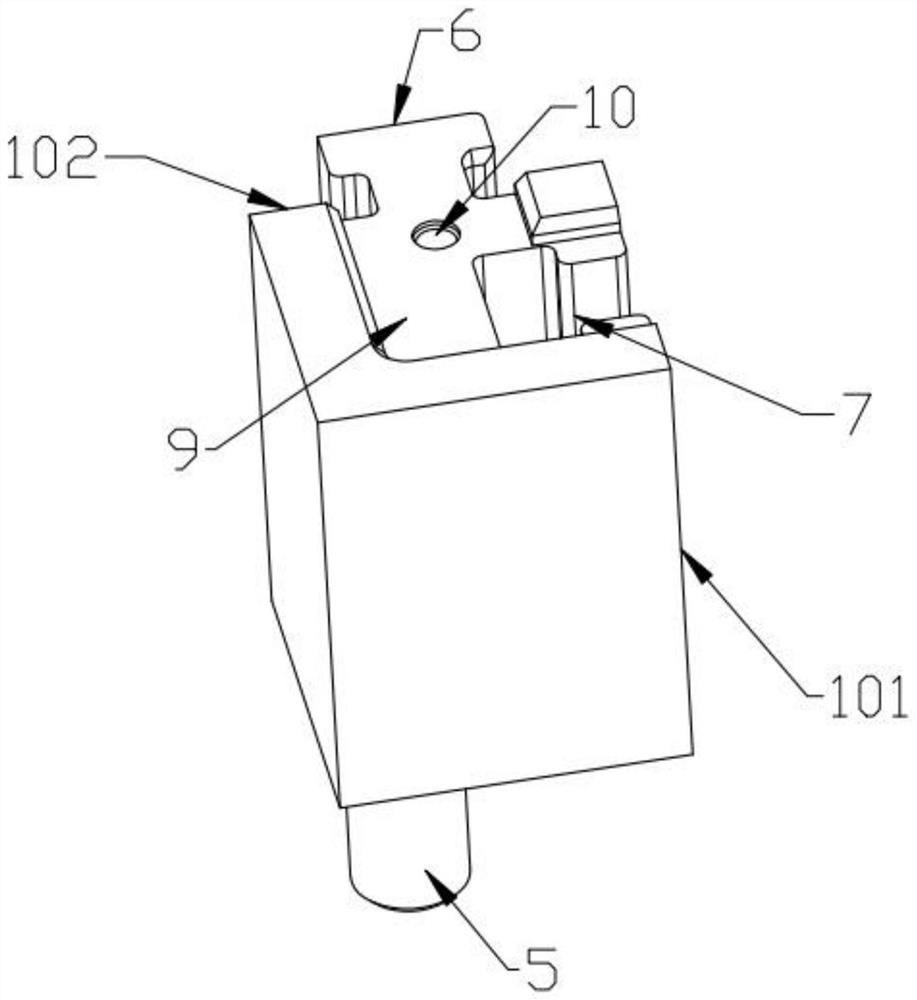

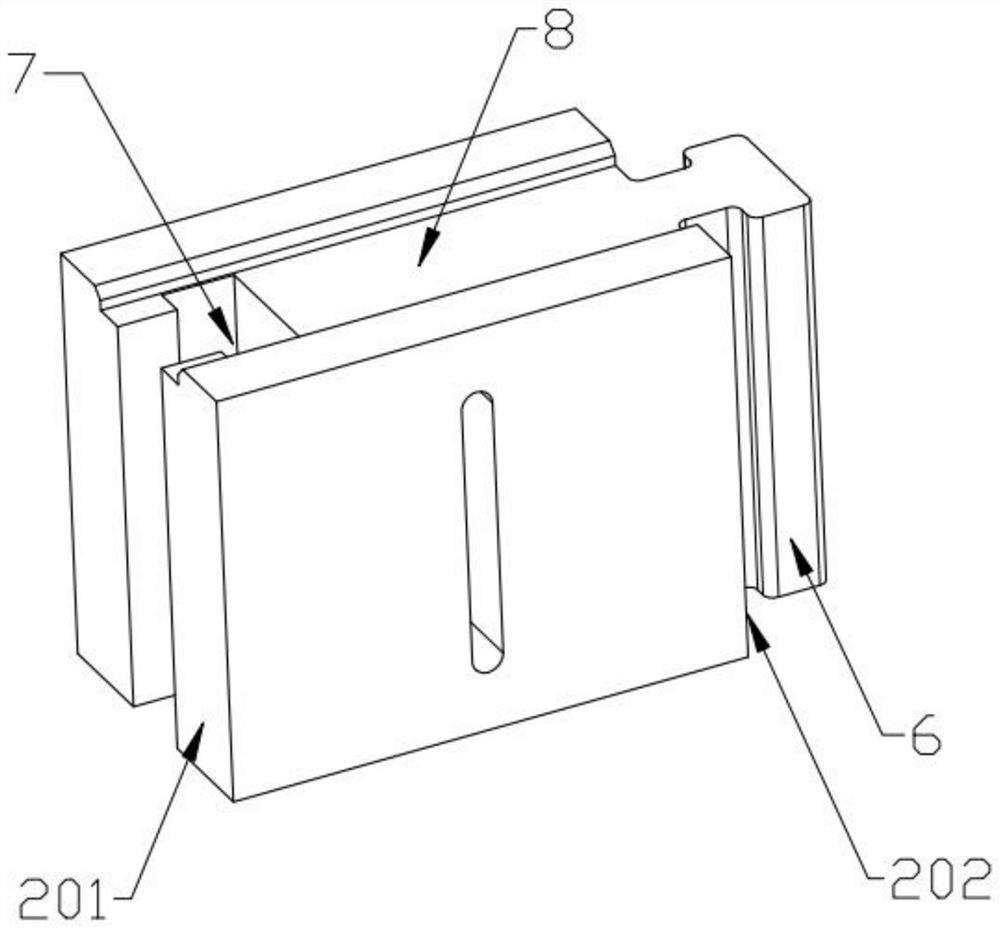

[0028] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings and embodiments.

[0029] like Figures 1 to 3 As shown in the figure, the general mold of the block-type PC component includes: a corner module 1, the corner module 1 has a first connecting surface 101 and a second connecting surface 102 that are perpendicular to each other, the first connecting surface 101 is provided with a female connector 7, and the first connecting surface 101 is provided with a female connector 7. The two connection surfaces 102 are provided with a male connector 6; the side module 2 has a first connection end 201 and a second connection end 202, and the second connection end 202 is on the side module 2 away from the first connection end 201 One end of the first connection end 201 is provided with a female connector 7, and the end surface of the second connection end 202 is provided with a male connector 6; the male connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com