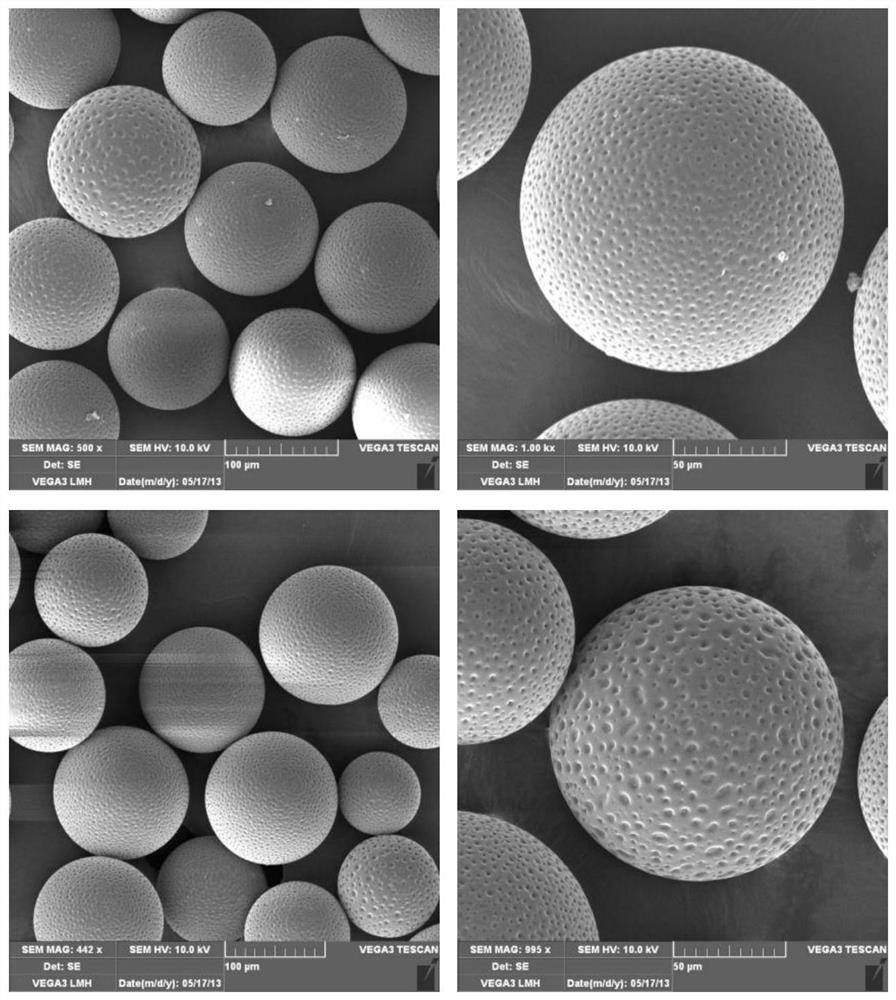

A pinhole-like depressed porous resin ball on the surface and its preparation method

A porous resin and pinhole technology, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve problems such as porous polymer microspheres that have not yet been seen, and achieve large-scale production, mass transfer, and Effect of high external surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Preparation of Surface Pinhole-like Depressed Porous Resin Balls

[0023] Take by weighing the aqueous solution 250g that is 1.75% gelatin, 0.2% polyvinyl alcohol (alcoholysis degree 80-88%, polymerization degree 1500-2000) and 0.5% sodium chloride that mass concentration is equipped with, add and be equipped with stirring and condensation In the three-necked bottle; weigh 0.70g of benzoyl peroxide, 7.00g of glycidyl methacrylate, 28.00g of styrene, 14.18g of ethylene glycol diacrylate, and 35.12g of toluene, fully dissolve and mix them into the three-necked bottle In the bottle, stand still for 5 minutes, start stirring at a stirring speed of 520rpm, after stirring for 30 minutes, raise the temperature of the system to 85°C, and react at a constant temperature for 6 hours; After treatment, the surface pinhole-shaped concave porous resin ball P (GMA-St-EGDA) can be obtained.

Embodiment 2

[0024] Example 2: Preparation of Surface Pinhole-like Depressed Porous Resin Balls

[0025] Take by weighing the aqueous solution 250g that is 1.75% gelatin, 0.2% polyvinyl alcohol (alcoholysis degree 80-88%, polymerization degree 1500-2000) and 0.5% sodium chloride that mass concentration is equipped with, add and be equipped with stirring and condensation In the three-necked bottle; weigh 0.76g of benzoyl peroxide, 7.60g of glycidyl methacrylate, 30.40g of styrene, 19.14g of ethylene glycol diacrylate, and 42.10g of toluene, fully dissolve, mix well and add to the three-necked bottle In the bottle, stand still for 5 minutes, start stirring at a stirring speed of 550rpm, after stirring for 30 minutes, raise the temperature of the system to 85°C, and react at a constant temperature for 6 hours; After treatment, the surface pinhole-shaped concave porous resin ball P (GMA-St-EGDA) can be obtained.

Embodiment 3

[0026] Example 3: Preparation of Surface Pinhole-like Depressed Porous Resin Balls

[0027] Take by weighing the aqueous solution 250g that is 1.75% gelatin, 0.2% polyvinyl alcohol (alcoholysis degree 80-88%, polymerization degree 1500-2000) and 0.5% sodium chloride that mass concentration is equipped with, add and be equipped with stirring and condensation In the three-necked bottle; weigh 1.00g of benzoyl peroxide, 10.00g of glycidyl methacrylate, 40.00g of styrene, 20.00g of ethylene glycol diacrylate, and 54.00g of toluene, fully dissolve and mix them into the three-necked bottle In the bottle, stand still for 5 minutes, start stirring at a stirring speed of 500 rpm, after stirring for 30 minutes, raise the temperature of the system to 85°C, and react at a constant temperature for 6 hours; After treatment, the surface pinhole-shaped concave porous resin ball P (GMA-St-EGDA) can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com