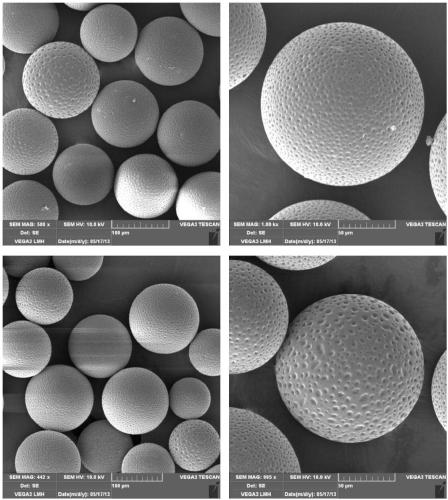

Surface pinhole sunken porous resin sphere and preparation method

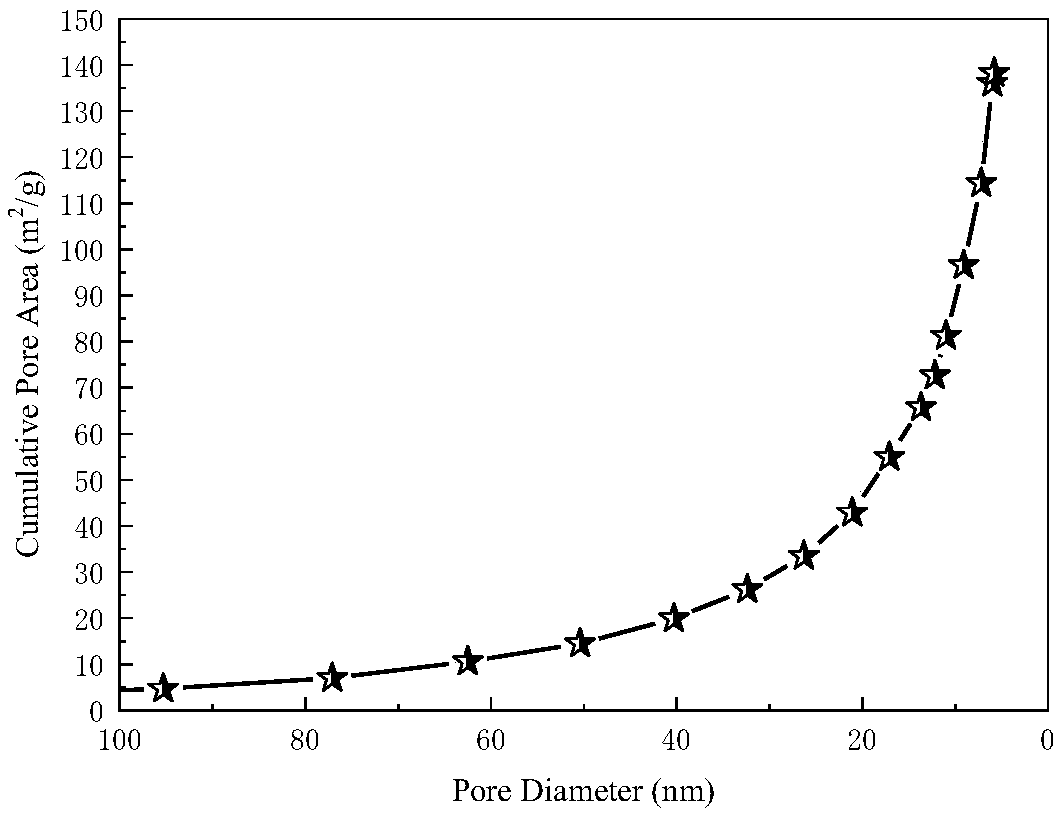

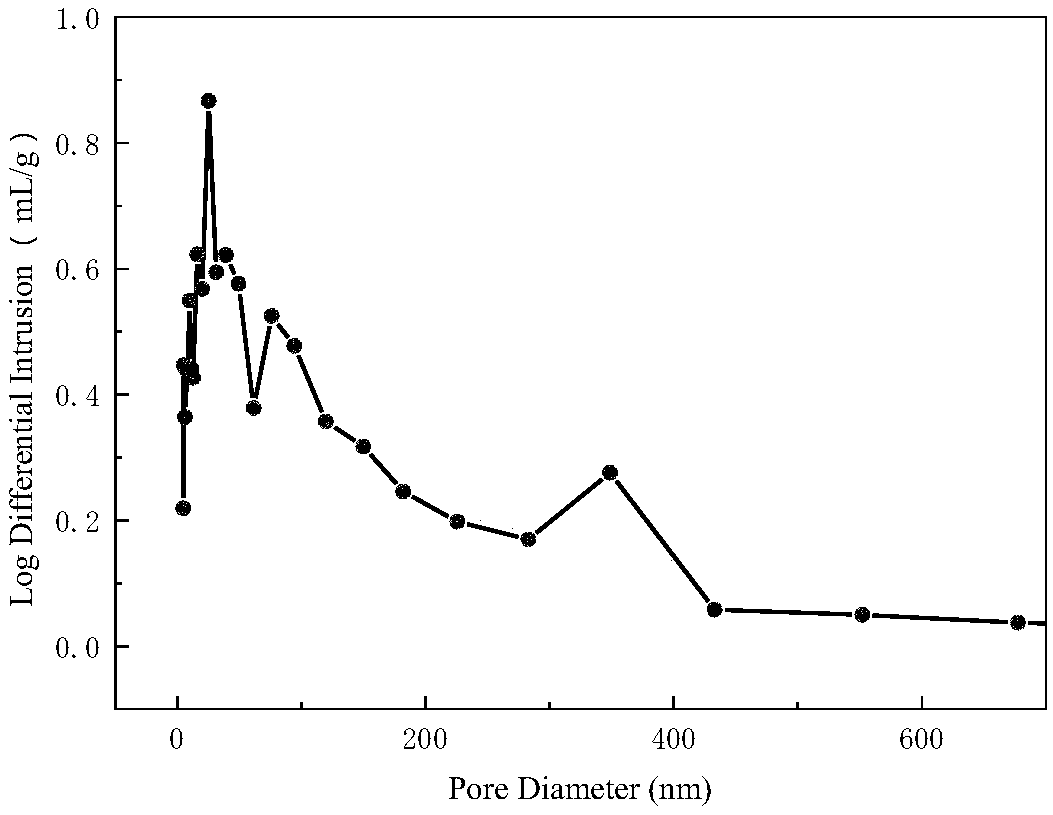

A porous resin and pinhole technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as porous polymer microspheres that have not yet been seen, and achieve the convenience of large-scale production, Ease of mass transfer, high external area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Preparation of Surface Pinhole-like Depressed Porous Resin Balls

[0023] Take by weighing the aqueous solution 250g that is 1.75% gelatin, 0.2% polyvinyl alcohol (alcoholysis degree 80-88%, polymerization degree 1500-2000) and 0.5% sodium chloride that mass concentration is equipped with, add and be equipped with stirring and condensation In the three-necked bottle; weigh 0.70g of benzoyl peroxide, 7.00g of glycidyl methacrylate, 28.00g of styrene, 14.18g of ethylene glycol diacrylate, and 35.12g of toluene, fully dissolve and mix them into the three-necked bottle In the bottle, stand still for 5 minutes, start stirring at a stirring speed of 520rpm, after stirring for 30 minutes, raise the temperature of the system to 85°C, and react at a constant temperature for 6 hours; After treatment, the surface pinhole-shaped concave porous resin ball P (GMA-St-EGDA) can be obtained.

Embodiment 2

[0024] Example 2: Preparation of Surface Pinhole-like Depressed Porous Resin Balls

[0025] Take by weighing the aqueous solution 250g that is 1.75% gelatin, 0.2% polyvinyl alcohol (alcoholysis degree 80-88%, polymerization degree 1500-2000) and 0.5% sodium chloride that mass concentration is equipped with, add and be equipped with stirring and condensation In the three-necked bottle; weigh 0.76g of benzoyl peroxide, 7.60g of glycidyl methacrylate, 30.40g of styrene, 19.14g of ethylene glycol diacrylate, and 42.10g of toluene, fully dissolve, mix well and add to the three-necked bottle In the bottle, stand still for 5 minutes, start stirring at a stirring speed of 550rpm, after stirring for 30 minutes, raise the temperature of the system to 85°C, and react at a constant temperature for 6 hours; After treatment, the surface pinhole-shaped concave porous resin ball P (GMA-St-EGDA) can be obtained.

Embodiment 3

[0026] Example 3: Preparation of Surface Pinhole-like Depressed Porous Resin Balls

[0027] Take by weighing the aqueous solution 250g that is 1.75% gelatin, 0.2% polyvinyl alcohol (alcoholysis degree 80-88%, polymerization degree 1500-2000) and 0.5% sodium chloride that mass concentration is equipped with, add and be equipped with stirring and condensation In the three-necked bottle; weigh 1.00g of benzoyl peroxide, 10.00g of glycidyl methacrylate, 40.00g of styrene, 20.00g of ethylene glycol diacrylate, and 54.00g of toluene, fully dissolve and mix them into the three-necked bottle In the bottle, stand still for 5 minutes, start stirring at a stirring speed of 500 rpm, after stirring for 30 minutes, raise the temperature of the system to 85°C, and react at a constant temperature for 6 hours; After treatment, the surface pinhole-shaped concave porous resin ball P (GMA-St-EGDA) can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com