Blast hole filling material and preparation method thereof, and blast hole filling method

A technology for filling materials and blast holes, which is applied in the fields of preparation, blast hole packing materials and blast hole packing, can solve the problems of increasing the difficulty of packing, easy dry shrinkage of the blast mud, loss of clogging effect, etc., so as to improve the construction efficiency and shorten the filling time. , the effect of low reaction heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

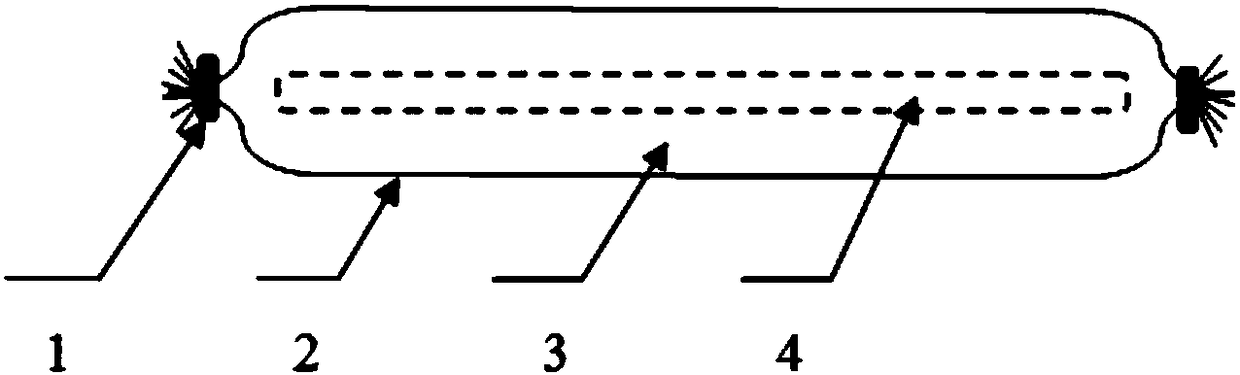

[0041] figure 1 The bagged blast hole packing material is prepared based on the method for preparing the blast hole packing material provided in the embodiments of the present invention. Such as figure 1 As shown, 1 is a sealing aluminum buckle, 2 is a packaging bag, 3 is a sealing material, and 4 is an internal support rod.

[0042]According to the preparation method of the blasthole filling material provided in the embodiment of the present invention, after mixing the components of the blasthole filling material according to a preset ratio, put it into a packaging bag, put a support rod in the packaging bag, and seal it. Based on the preparation method of the blasthole filling material provided by the embodiment of the present invention, through reasonable proportioning and preparation process, the blasthole filling material can meet the blasting construction requirements and the performance requirements of the filling material, and has the characteristics of no stirring, e...

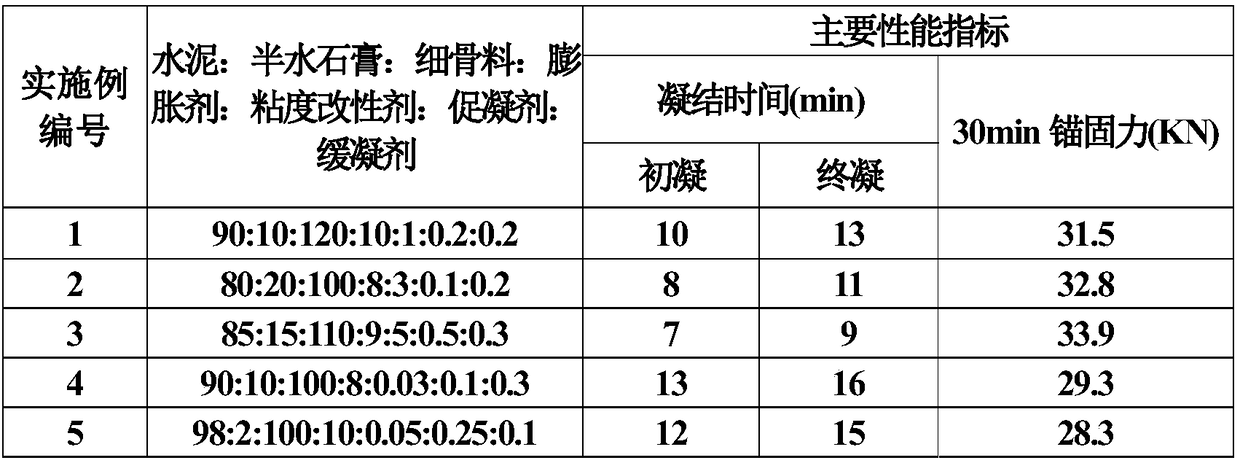

Embodiment 1

[0045] Cement, hemihydrate gypsum, fine aggregate, expansion agent, viscosity modifier, coagulant, retarder according to figure 1 Among them, the cement is selected from 52.5 sulfoaluminate cement, the hemihydrate gypsum is selected from α hemihydrate gypsum, the fine aggregate is selected from quartz sand with a particle size of 0.15mm-2.36mm, and the expansion agent is selected from UEA common type expansion agent , The viscosity modifier is selected from inorganic thixotropic agent, the coagulation accelerator is selected from lithium chloride, and the retarder is selected from tartaric acid. The performance test is carried out on the blasthole filling material formed after mixing, wherein the setting time of the test is carried out according to the GB / T1346-2011 standard test method.

[0046] 30min anchoring force test method, soak the blasthole plugging material in water and insert it into a rock hole with a diameter of 60mm, and use a press to test its anchoring force af...

Embodiment 2-3

[0050] According to the ingredients listed in Example 1, after changing the distribution ratio of each component, mix them. The mixing ratio and performance of each component are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com