Ganoderma spore wall breaking method

A technology of Ganoderma lucidum spores and Ganoderma lucidum spore powder, which can be used in pharmaceutical formulations, plant raw materials, plant/algae/fungus/moss components, etc. It can solve the problems of loss of active ingredients of Ganoderma lucidum spores, low wall breaking rate, etc., to reduce the difficulty of dissolution, The effect of improving the wall breaking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

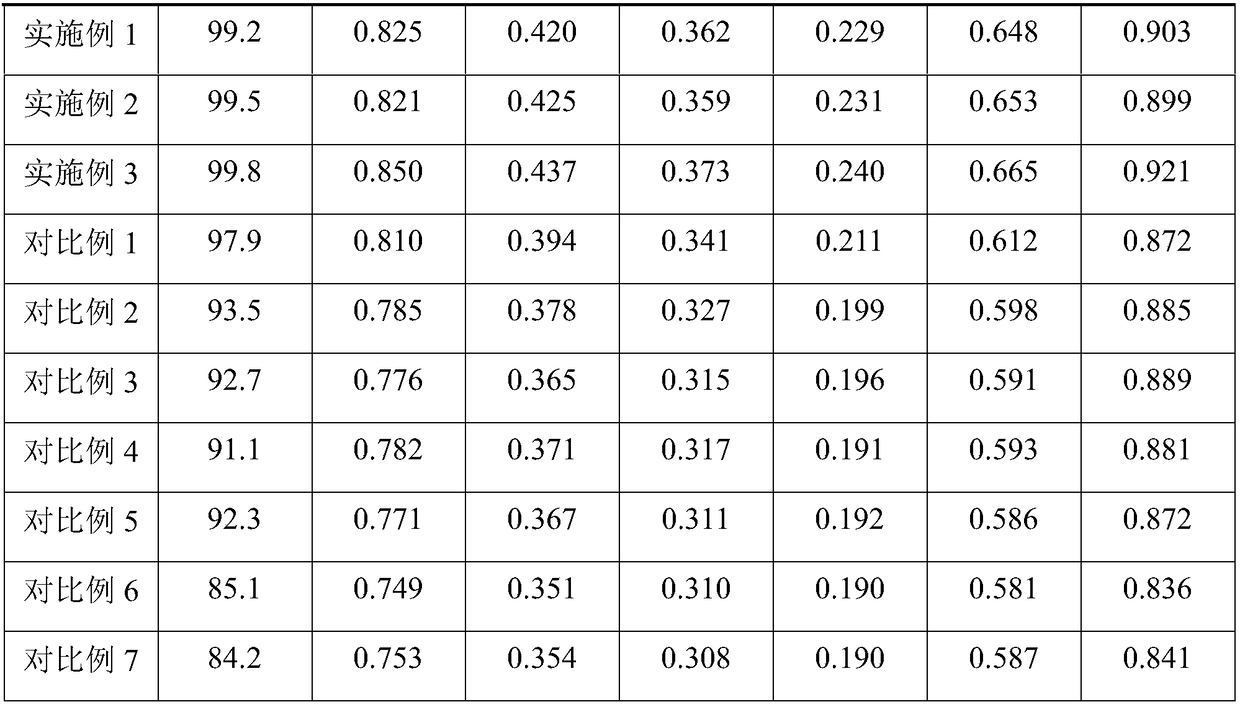

Embodiment 1

[0029] A method for breaking ganoderma spores, comprising the following steps:

[0030] (1) Pulverization: pulverize the ganoderma spores, and cross a 60-80 mesh sieve to obtain the ganoderma spore powder;

[0031] (2) Oscillation: mix Ganoderma lucidum spore powder, distilled water, and lysozyme in a weight ratio of 1:2:0.01, and oscillate at 25°C for 2 hours to obtain an oscillating mixture;

[0032] (3) Enzymolysis: Mix the oscillating mixed solution and the mixed enzyme solution at a mass ratio of 1:0.3 and then perform enzymolysis. The enzymolysis temperature is 40°C and the enzymolysis time is 4 hours to obtain an enzymolysis solution; the mixed enzyme solution Including cellulase, hemicellulase and pectinase, the concentrations of cellulase, hemicellulase and pectinase are 0.5g / L, 0.3g / L, 0.4g / L respectively;

[0033] (4) Ultrasonic treatment: filter the enzymolysis solution, remove the filtrate, mix the obtained solid with the cellulase solution at a weight ratio of 1...

Embodiment 2

[0039] A method for breaking ganoderma spores, comprising the following steps:

[0040] (1) Pulverization: pulverize the ganoderma spores, and cross a 60-80 mesh sieve to obtain the ganoderma spore powder;

[0041] (2) Oscillation: mix Ganoderma lucidum spore powder, distilled water, and lysozyme in a weight ratio of 1:4:0.02, and oscillate at 35°C for 1 hour to obtain an oscillating mixture;

[0042] (3) Enzymolysis: Mix the oscillating mixed solution and the mixed enzyme solution at a mass ratio of 1:0.8 and then perform enzymolysis. The enzymolysis temperature is 50°C and the enzymolysis time is 3 hours to obtain an enzymolysis solution; the mixed enzyme solution Including cellulase, hemicellulase and pectinase, the concentrations of cellulase, hemicellulase and pectinase are 0.8g / L, 0.6g / L, 0.7g / L respectively;

[0043] (4) Ultrasonic treatment: filter the enzymolysis solution, remove the filtrate, mix the obtained solid with the cellulase solution at a weight ratio of 1:...

Embodiment 3

[0049] A method for breaking ganoderma spores, comprising the following steps:

[0050] (1) Pulverization: pulverize the ganoderma spores, and cross a 60-80 mesh sieve to obtain the ganoderma spore powder;

[0051](2) Oscillation: mix Ganoderma lucidum spore powder, distilled water, and lysozyme in a weight ratio of 1:3:0.15, and oscillate at 30°C for 2 hours to obtain an oscillating mixture;

[0052] (3) Enzymolysis: Mix the oscillating mixed solution and the mixed enzyme solution at a mass ratio of 1:0.5 and then perform enzymolysis. The enzymolysis temperature is 45°C and the enzymolysis time is 4 hours to obtain an enzymolysis solution; the mixed enzyme solution Including cellulase, hemicellulase and pectinase, the concentrations of cellulase, hemicellulase and pectinase are 0.6g / L, 0.5g / L, 0.6g / L respectively;

[0053] (4) Ultrasonic treatment: filter the enzymatic solution, remove the filtrate, mix the obtained solid with the cellulase solution at a weight ratio of 1:6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com