A kind of diffusion film and its application

A technology of diffuser film and diffuser coating, which is applied to instruments, optics, diffusing components, etc., can solve the problems of increasing the specific surface area of the coating surface, increasing the surface tension of the coating, and poor adhesion between the diffusing film and the ink coating. The effect of improving the poor adhesion of the coating, increasing the surface tension of the coating, and excellent diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

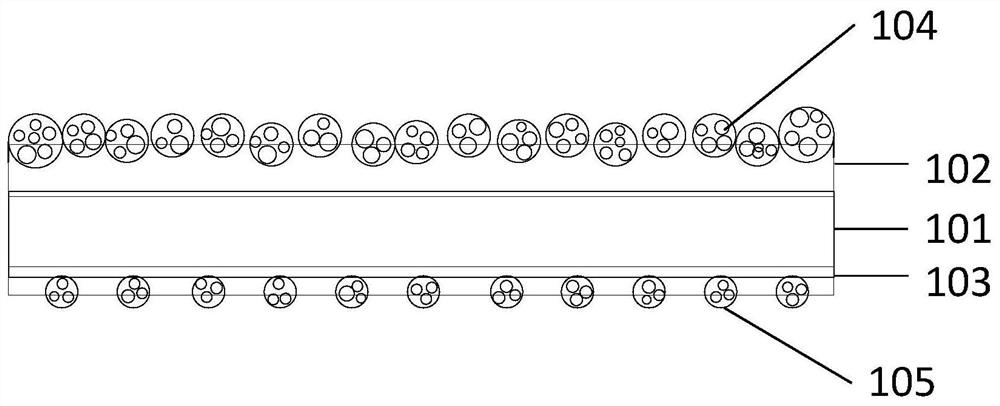

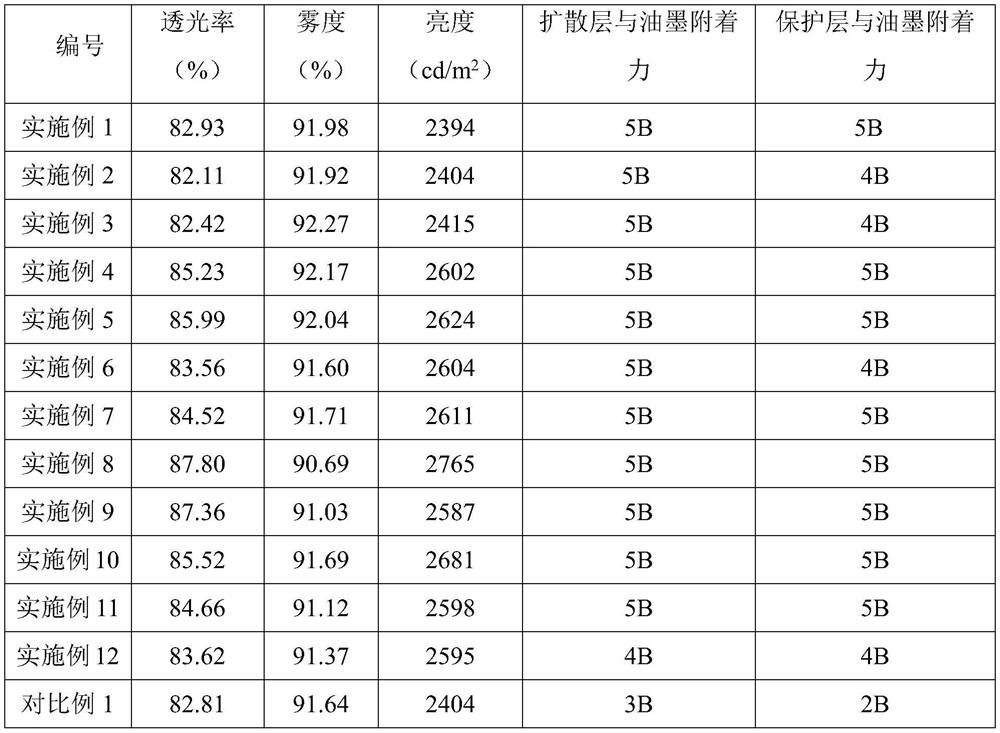

[0046] The invention provides a diffusion film, which comprises a transparent substrate, a diffusion coating and a protective coating; the diffusion coating and the protective coating are respectively located on the upper and lower surfaces of the transparent substrate. Wherein, the transparent substrate is polyethylene terephthalate, and the thickness of the transparent substrate is 25um; the diffusion coating contains: 100 parts by mass of polyacrylic resin adhesive, 30 parts by mass of polyacrylic resin adhesive with a particle size of 3um Diffused porous particles, the diffused porous particles are polymethyl methacrylate; the protective coating contains: 100 parts by mass of polyurethane adhesive, 0.5 parts by mass of anti-blocking porous particles with a particle size of 1um, the anti-blocking The cohesive porous particles are polymethyl methacrylate.

Embodiment 2

[0048] As in the diffusion film provided in Example 1, wherein the transparent substrate is polyethylene, and the thickness of the transparent substrate is 75 μm; the diffusion coating contains: 100 parts by mass of polyurethane adhesive, 50 parts by mass of diffusion film with a particle size of 10 μm Porous particles, the diffusion porous particles are polymethyl methacrylate; the protective coating contains: 100 parts by mass of polyurethane adhesive, 1 part by mass of anti-blocking porous particles with a particle size of 3 μm, the anti-blocking The porous particles are polybutyl methacrylate.

Embodiment 3

[0050] The diffusion film provided in Example 1, wherein the transparent substrate is polycarbonate, and the thickness of the transparent substrate is 80 μm; the diffusion coating contains: 100 parts by mass of polyurethane adhesive, and the particle size of 100 parts by mass is 15 μm The diffusion porous particles, the diffusion porous particles are polymethyl methacrylate; the protective coating contains: 100 parts by mass of polyacrylic resin adhesive, 2 parts by mass of anti-blocking porous particles with a particle size of 5 μm, The anti-blocking porous particles are polyamide resins.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com