Optical fiber sensing system and measurement method for simultaneous measurement of liquid level and liquid temperature

An optical fiber sensing system and liquid temperature technology, applied in the optical fiber sensing system and its measurement field, can solve the problems of small measurement range, easily affected by the external environment, low measurement accuracy, etc., and achieve a wide range of high-precision liquid The effect of level and liquid temperature monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

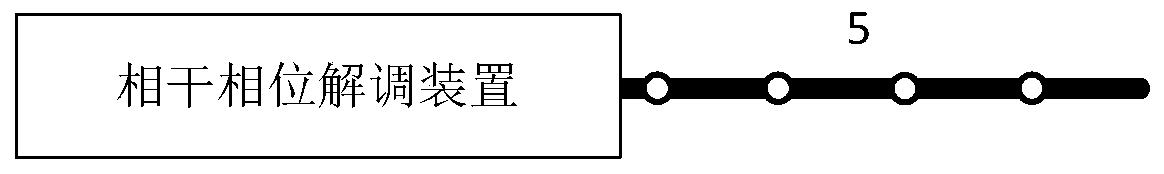

[0026] The invention relates to an optical fiber sensing system for simultaneous measurement of liquid level and liquid temperature, such as figure 1 As shown, this embodiment includes: a threaded package tube, a microstructured optical fiber 5 and a coherent phase demodulation device. Use a 248nm UV laser to focus the beam and write scatter enhancement points on the anti-bending single-mode fiber to make microstructure fiber 5. The distance between adjacent scatter enhancement points is 2m, and the reflectivity is -50dB; the threaded package tube is made of aluminum with an outer diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com