Adjustable double-layer metal rubber damping vibration absorber and working method thereof

A double-layer metal, metal-rubber technology, used in springs/shock absorbers, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve problems such as short service life, narrow operating temperature range, and impact on the performance of shock absorbers. , to achieve the effect of improving comprehensive performance, expanding application fields and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

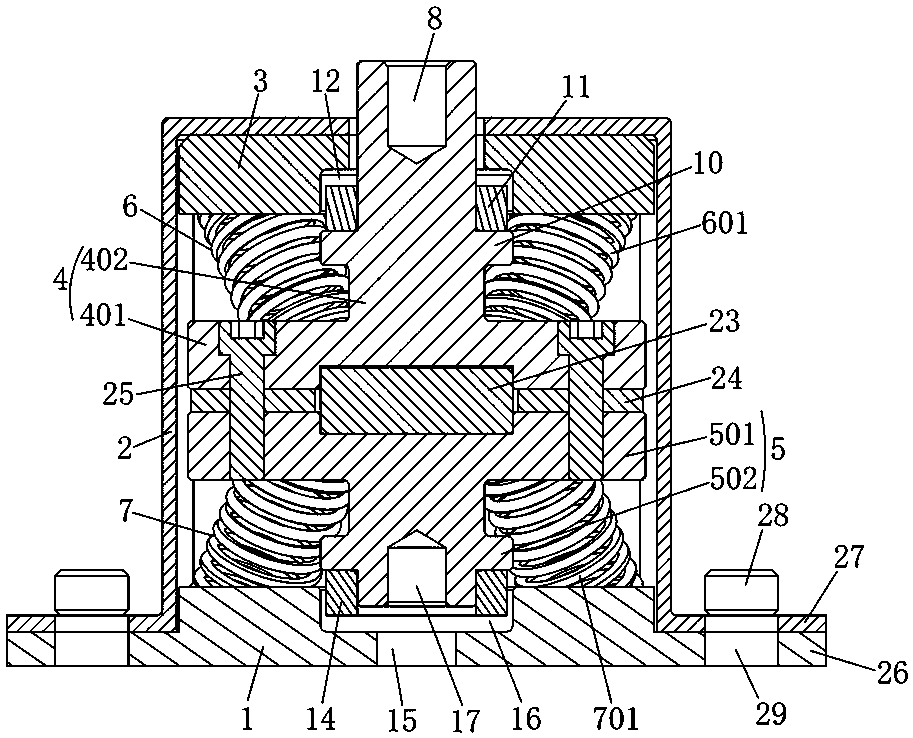

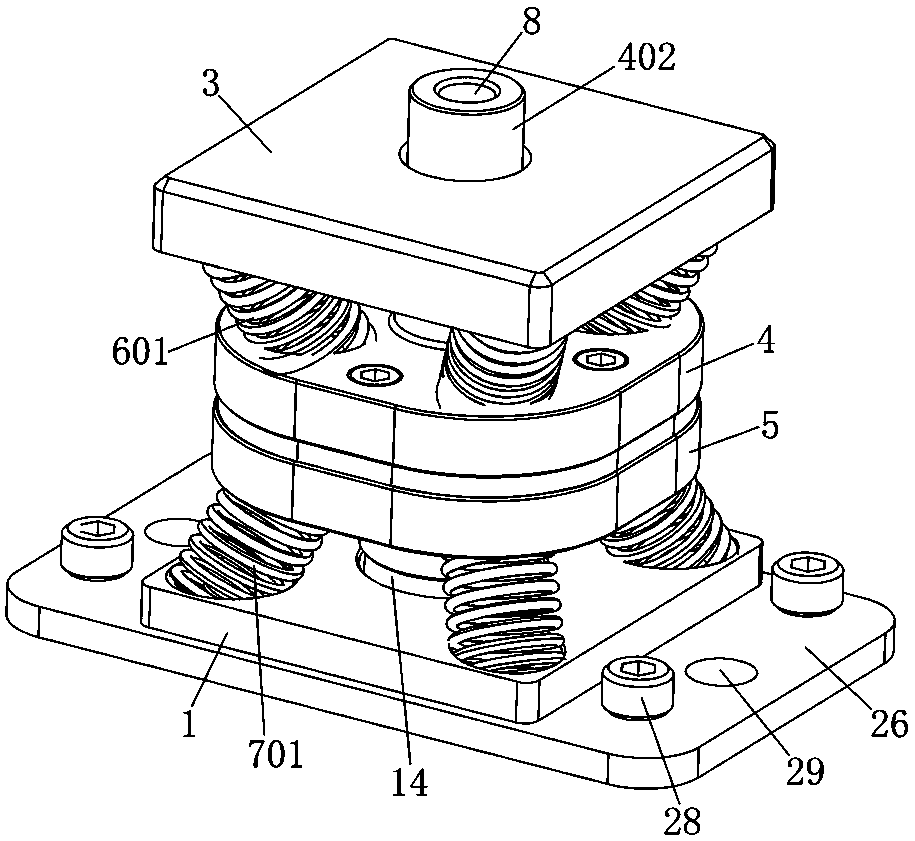

[0029] In order to explain the present invention more clearly, the present invention will be further described below in conjunction with the drawings and embodiments. Obviously, the drawings listed below are only some specific embodiments of the present invention.

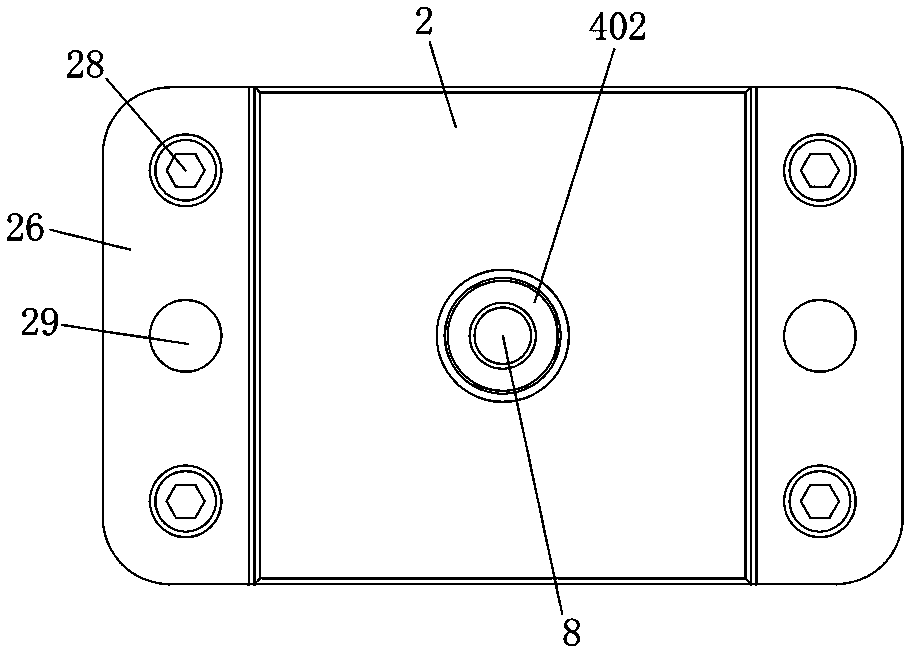

[0030] Such as Figure 1-8 As shown, an adjustable double-layer metal rubber damping shock absorber of the present invention includes a base 1 and a shell 2 fixedly connected to the base 1, and the inner top surface of the shell 2 and the base 1 are sequentially arranged from top to bottom. Coaxially provided with end cover 3, upper fixed bracket 4 and lower fixed bracket 5, upper spring assembly 6 is connected between described end cover 3 and upper fixed bracket 4, between described upper fixed bracket 4 and lower fixed bracket 5 A metal rubber damping element is provided, and a lower spring assembly 7 is connected between the lower fixing bracket 5 and the base 1 .

[0031] In this embodiment, the upper fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com