Installation and positioning construction method of buried rubber waterstop

A technology of rubber waterstop and construction method, which is applied in the processing of building materials, construction, building components, etc., can solve the problems of increasing operation and maintenance costs, not stopping water, hidden dangers of buildings, etc., and can improve the quality of installation and use , The ability of external force is increased, and the effect of not easy displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0037] The present invention is achieved through the following technical solutions:

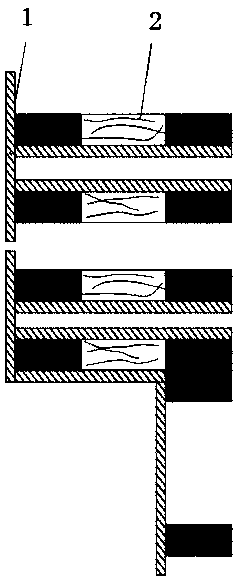

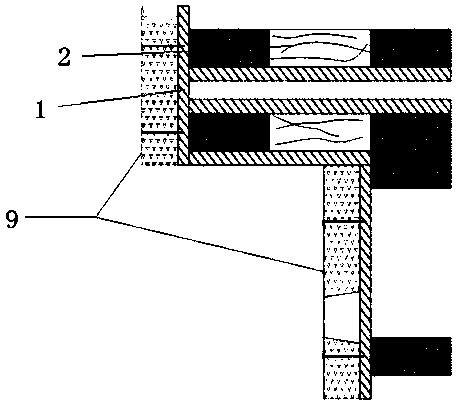

[0038] (1) According to the requirements of the design drawings, the upper and lower positioning templates of the buried rubber waterstop are processed. Each template is fixed with plywood 1 and sub-keel 2. See details figure 1 ;

[0039] (2) According to the size of the deformation seam, cut the polyethylene foam plastic board as the filling material for the deformation seam, and then use the foam electric knife to combine the polyethylene foam plastic board with the middle hollow ring of the buried rubber waterstop 7, According to the diameter of the hollow ring, cut a semicircular groove of the same diameter on the edge of the polyethylene foam plastic plate, that is, the corresponding seat groove;

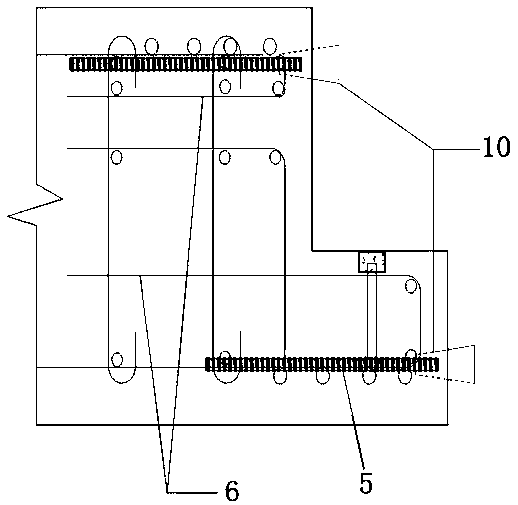

[0040] (3) Bind the steel bar 6 of the water stop belt,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com