Waterproof coil construction method

A construction method and technology for waterproofing membranes, which are applied in infrastructure engineering, tools for roof engineering, and roofs using flexible materials, etc., can solve problems such as construction difficulties, hidden dangers of water seepage, and narrow operating space, and achieve low construction costs. , Waterproof effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

[0034] A method for waterproofing membrane construction, comprising the following steps:

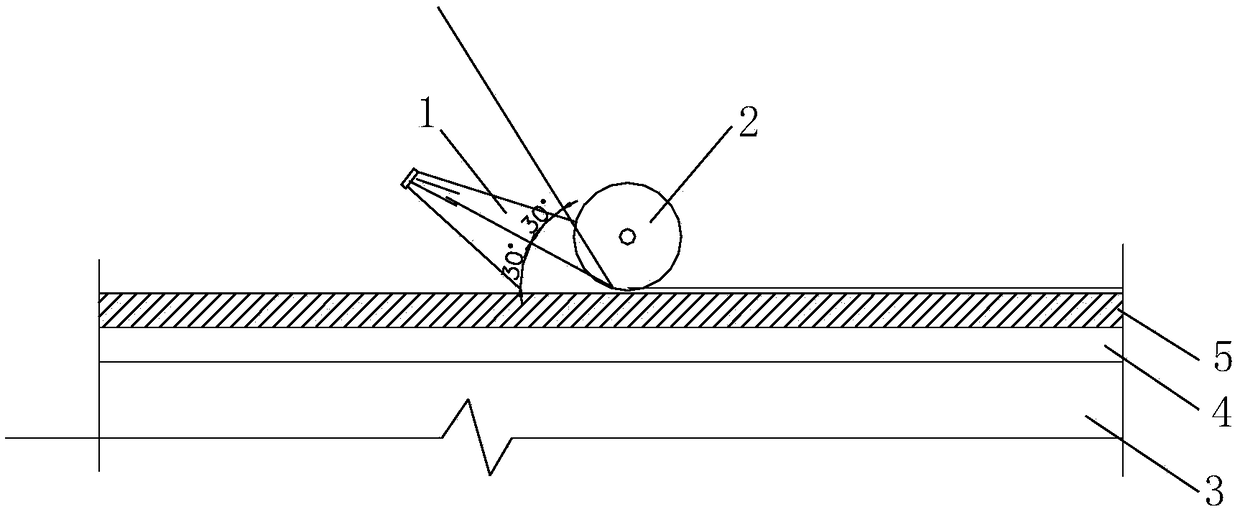

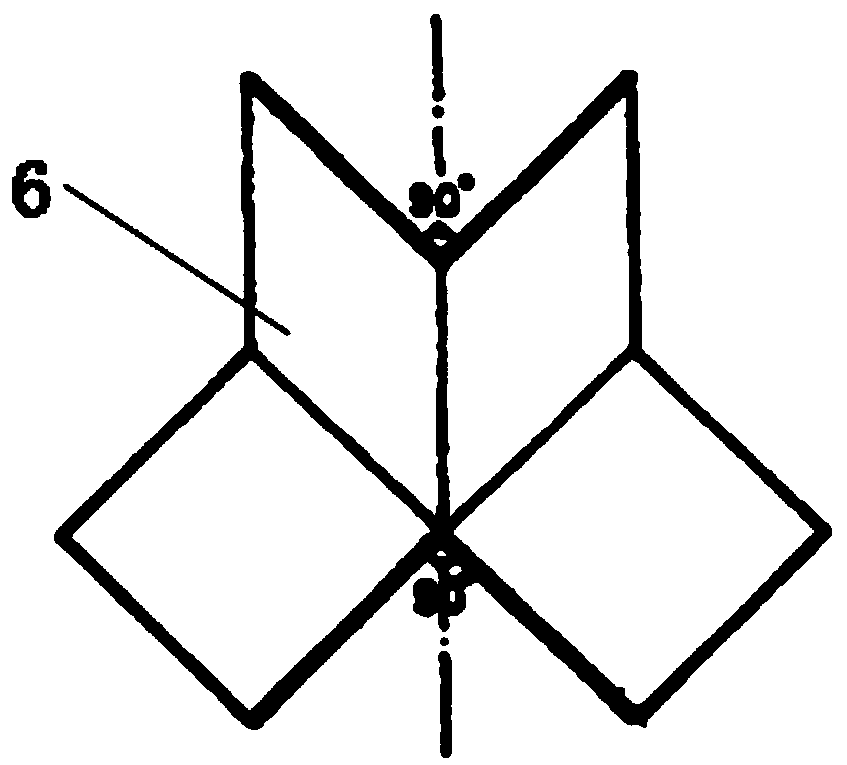

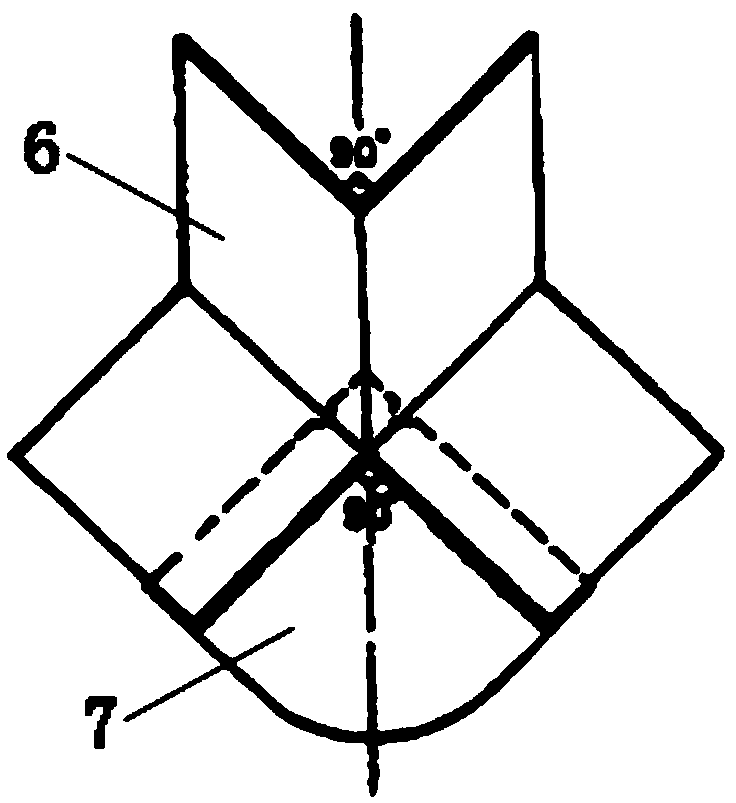

[0035] 1) The base layer 3 is cleaned up, the base surface is treated flat, and the yin and yang corners are made into a circular arc or 135° angle; the surface of the base layer 3 is flat, smooth, and free of looseness. flatten;

[0036] 2) The surface of the base layer 3 is dry, and the moisture content is not more than 9%. Cover the surface of the base layer 3 completely with the coiled material 2 and let it stand for more than 3 hours. Dew phenomenon, that is, the moisture content of the base layer 3 is considered to be less than 9%;

[0037] 3) Brush the base treatment agent 4: use a brush to paint the cold base oil on the surface of the base 3, use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com